TM 55-2840-241-23

Change 23 7-19

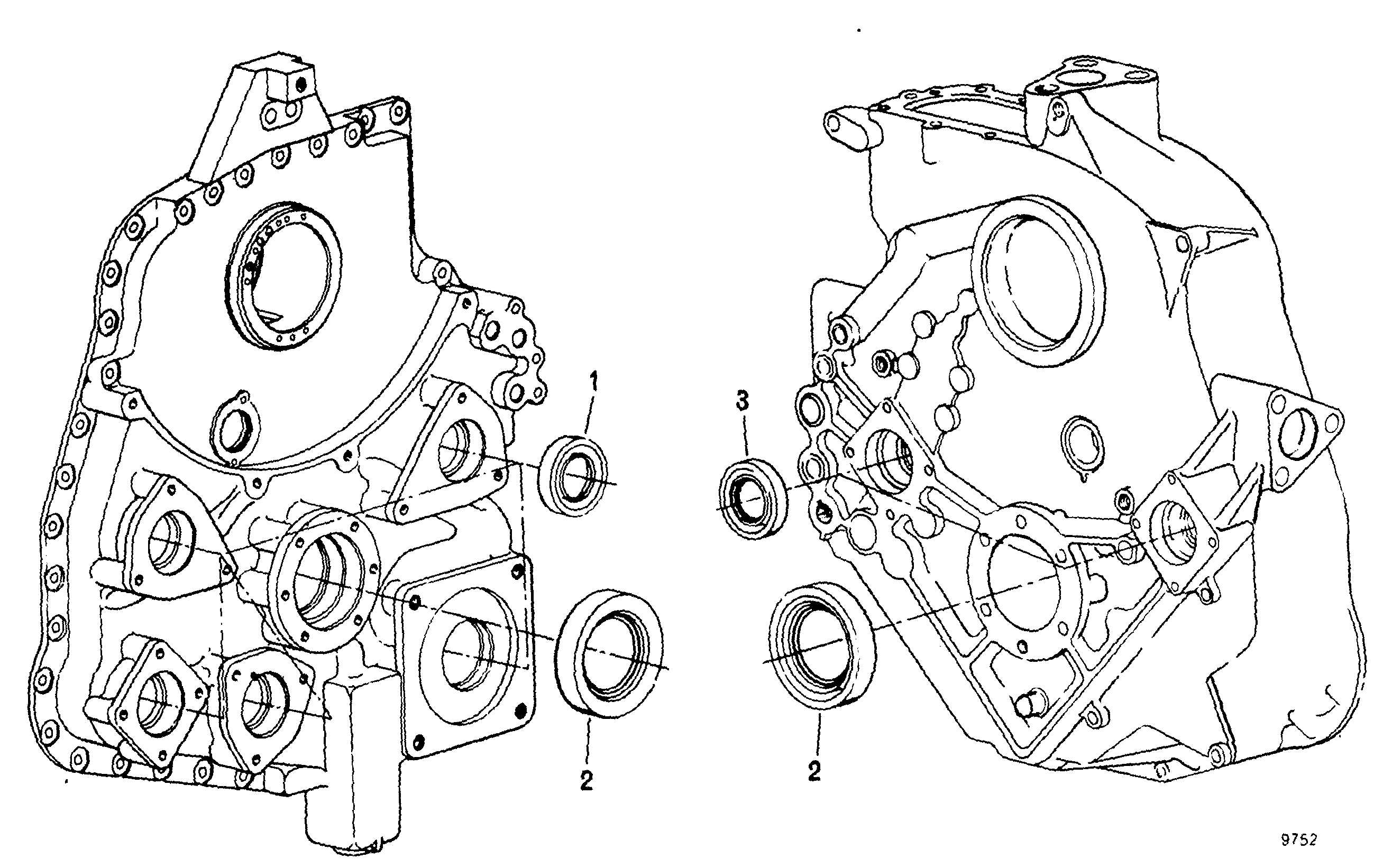

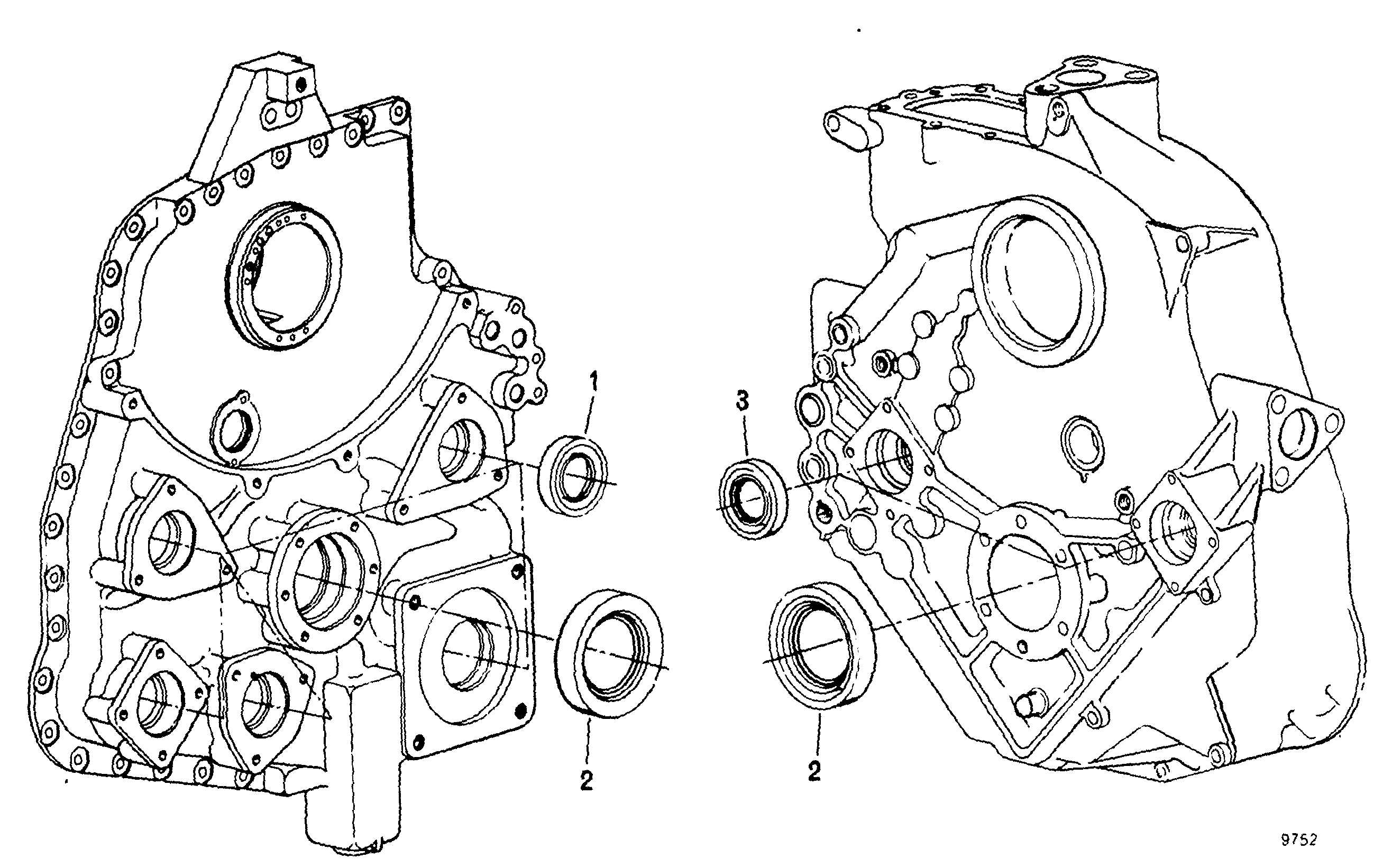

1.

Accessory pad seals

2.

Power takeoff pad seals

3.

Tachometer pad seals

Figure 7-15. Gearbox External Seals

7-29. Gearbox Housing and Cover Painting.

Repair damaged paint on the external surfaces of the

gearbox housing and cover as follows:

a.

Clean the damaged area with a clean cloth satu-

rated with solvent (item 3, table 2-2).

b.

Using emery cloth (item 23, table 2-2), abrade an

area slightly larger than the damaged area. Feather the

edges of the abraded area.

c.

Clean the area as in step a and dry using a blast

of clean compressed air.

d.

Chrome pickle the cleaned area per TM

1-1500-344-23.

e.

Wipe the abraded area with paint thinner (item

24, table 2-2) .

f.

Apply medium gray corrosion resistant paint (item

25, table 2-2) to the abraded area,

g.

Air dry at least one hour before handling. Heat

may be applied with a heat lamp to speed up curing;

however, do not exceed 300 F. Approximately 20 min-

utes will be required for the heat cure.

7-30. Outer Combustion Case Weld Repair.

Weld repair cracks in the outer combustion case as

follows: (See figure 7-5.)

a.

Remove surface contamination using a stainless

steel wire brush.

b.

Clean the area with acetone (item 28, table 2-2)

using a clean cloth for the application.

c.

Weld cracks using inert gas arc and class 6 weld

rod (item 29, table 2-2) . Apply 1/8 in. wide stringer bead

using medium heat input. Cool each bead with a wet cloth

immediately. Do not apply another bead until cool

enough to touch by hand.

d.

Inspect the weld for undercut, cracking, and dis-

continuities. There must be not evidence of undercutting

and cracking. If cracks in the well are suspected, refer

7-31.Compressor Discharge Air Tube Weld Repair.

Weld repair cracks in the compressor discharge air

tubes as follows:

to TM 1-1520-254-23, Technical Manual Aviation Unit

Maintenance (AVUM) and Aviation Intermediate Main-

tenance (AVIM) Manual Nondestructive Inspection

Procedure for OH-58 Helicopter Series.