TM55-2840-251-23

6-8

COMBUSTOR DRAIN VALVE (Continued)

6-8-3 INSPECTION

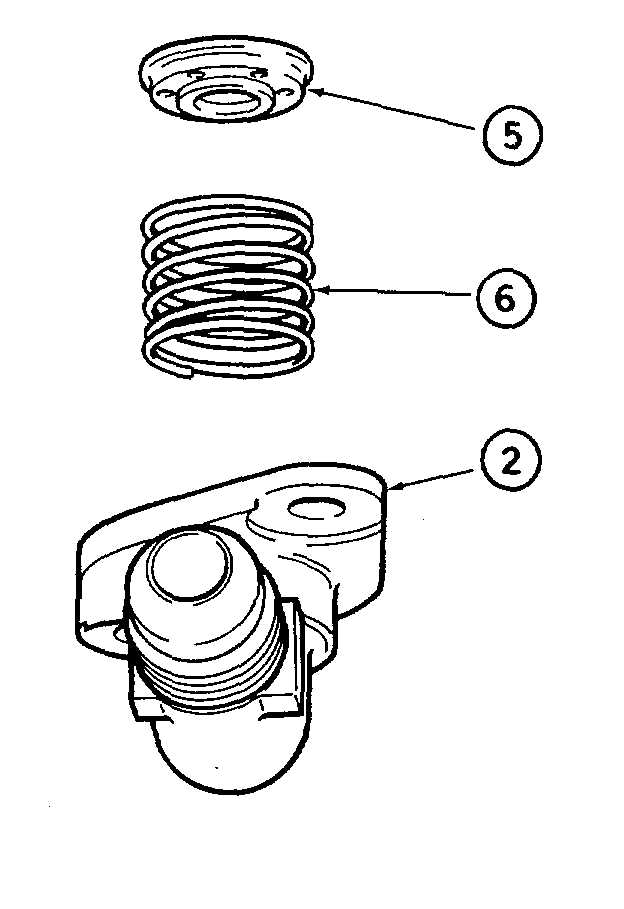

1.

Inspect surface of valve (5) for nicks, gouges,

scores, scratches and burrs. Particular attention must

be given to sealing surface around counterbore in spring

side of valve.

2. Check for blockage of six holes in valve. Holes

which are blocked, may be cleared by passing a No. 58

drill (0.042 inch) through by hand.

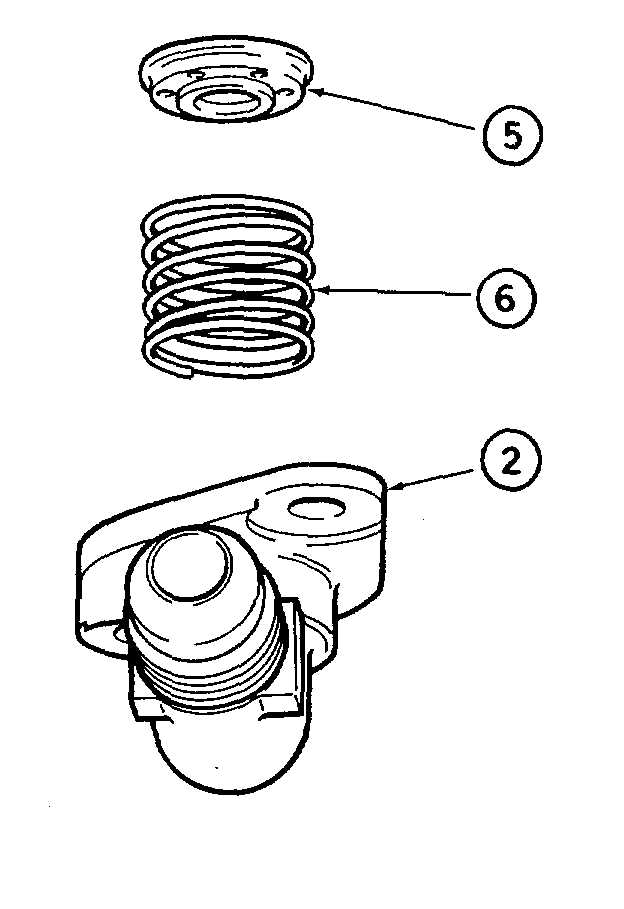

3.

Check for blockage in valve body (2). Clear any

blockage with clean, filtered, dehydrated compressed

air.

4. Check large bore of valve body for surface defects,

especially on sealing surface of projection.

5. Check spring (6) for distortion. Spring must pass

freely over a 0.530 inch dia gage rod and through a

0.600 inch gage tube. Reject spring if distorted.

6. Check compression loading of spring. Load

required to compress spring to 0.250 inch length should

be 4 oz. to 8 oz. Reject spring if not within limits.

7.

Examine spring for uniformity of coil spacing and

insure that surfaces are free from pits, scratches, nicks

and other defects, which may be detrimental to the

fatigue resistance of the spring.

GO TO NEXT PAGE

6-39