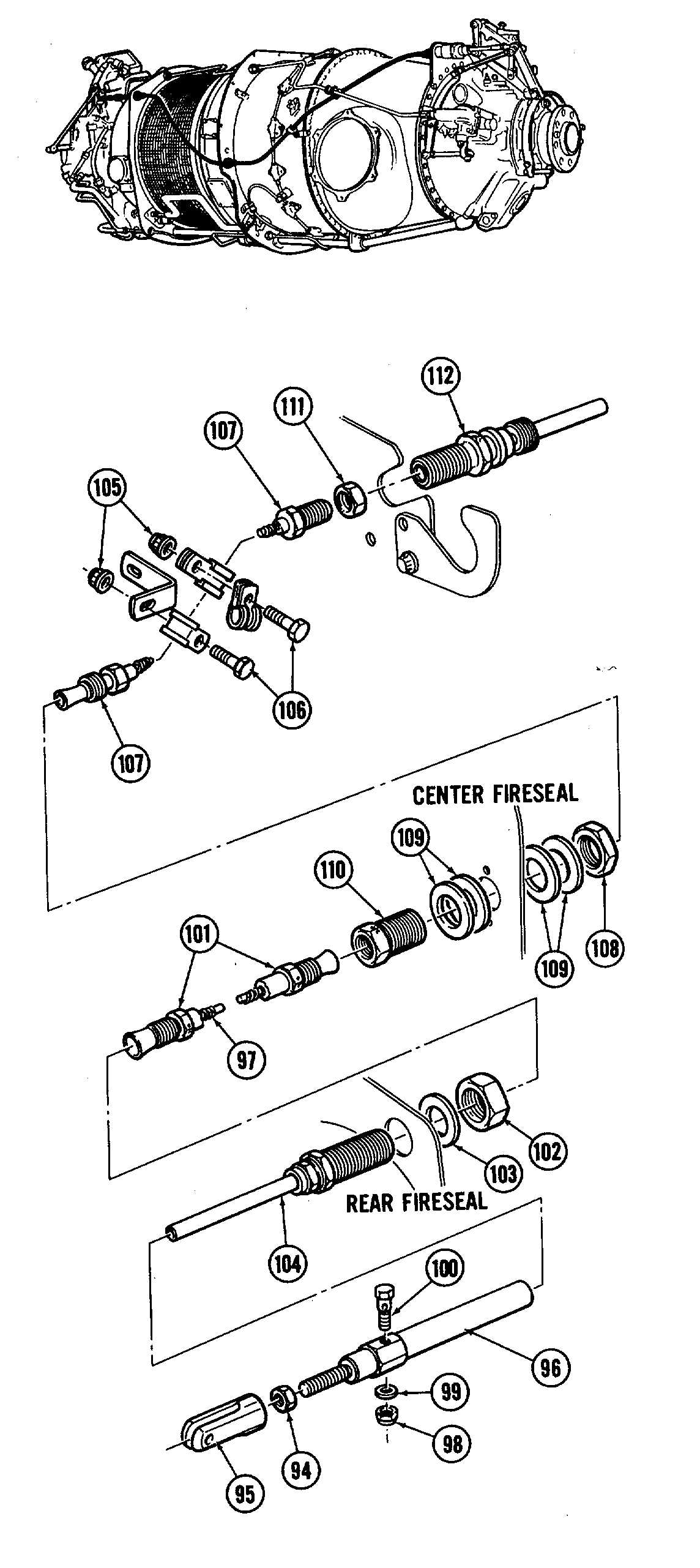

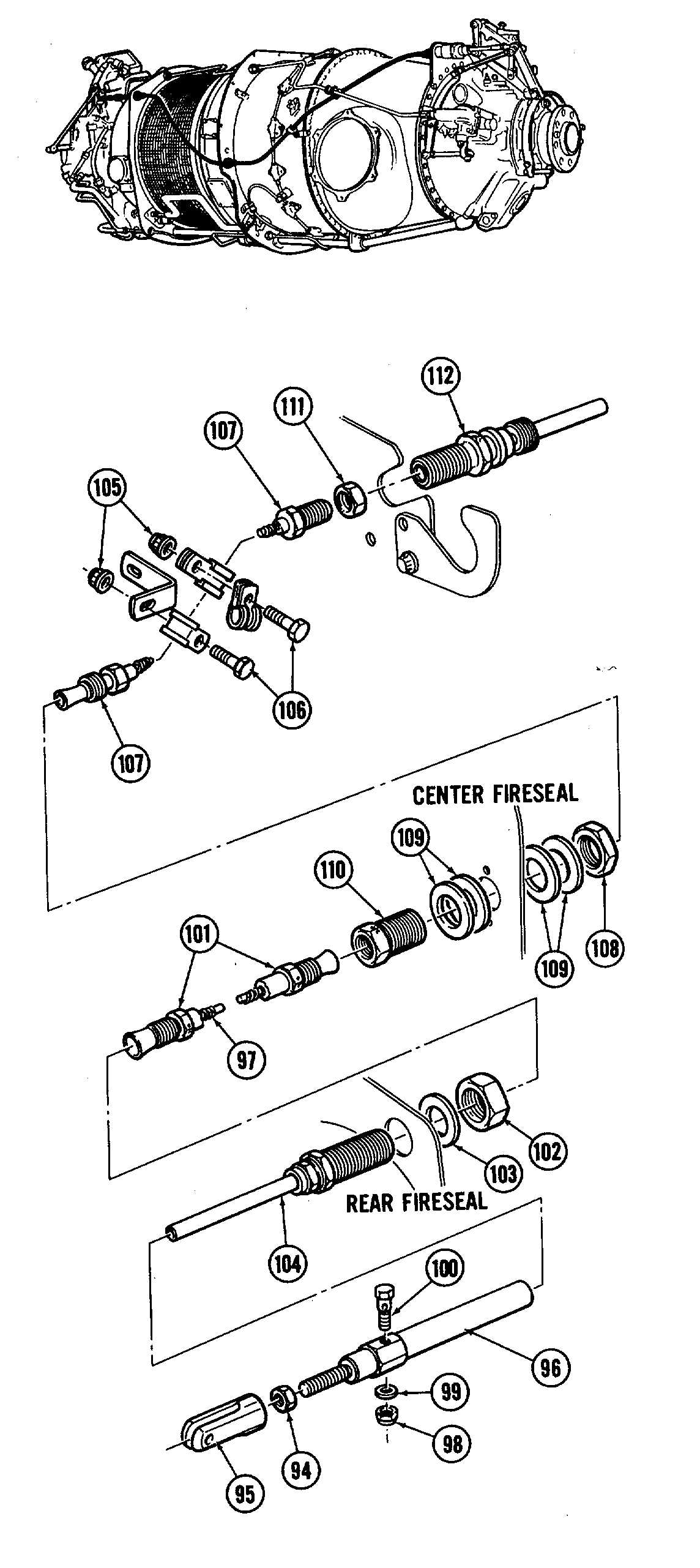

TM55-2840-251-23

10-3 PROPELLER REVERSING GEAR (Continued)

10-3-3 INSTALLATION

1.

Lubricate (E. 81) and install swivel (112) and nut

(111). Torque to 80 to 100 inch-pounds and lockwire

(E. 5).

2.

Install bushing (110), washers (109) and nut (108).

Torque bushing and nut to 80 to 100 inch-pounds and

lockwire (E. 5).

3.

Install casing (107). Torque casing to 40 to 60

inch-pounds and lockwire (E. 5).

4.

Install bolt (106) and nut (105). Torque nut to 32

to 36 inch-pounds.

5.

Install swivel (i04), washer (103) and nut (102).

Torque nut to 80 to 100 inch-pounds and lockwire (E.

5).

6.

Install casing (101). Torque casing to 40 to 60

inch-pounds and lockwire (E. 5).

7.

Install clamp (100), wire rope (97) in terminal (96)

insuring that wire rope passes safety hole in terminal.

Inspect.

8.

Install washer (99) and nut (98). Torque nut to 32

to 36 inch-pounds.

9.

Feed wire rope into swivel (104).

10.

Install clevis (95) and locknut (94). Insure that

threads of terminal pass safety hole in clevis. Inspect.

11. Torque locknut (94) to 16 to 18 inch-pounds and

lockwire (E. 5).

GO TO NEXT PAGE

10-15