TM55-2840-251-23

10-4

AIR LINES AND FITTINGS (Continued)

10-4-7

TESTING

1.

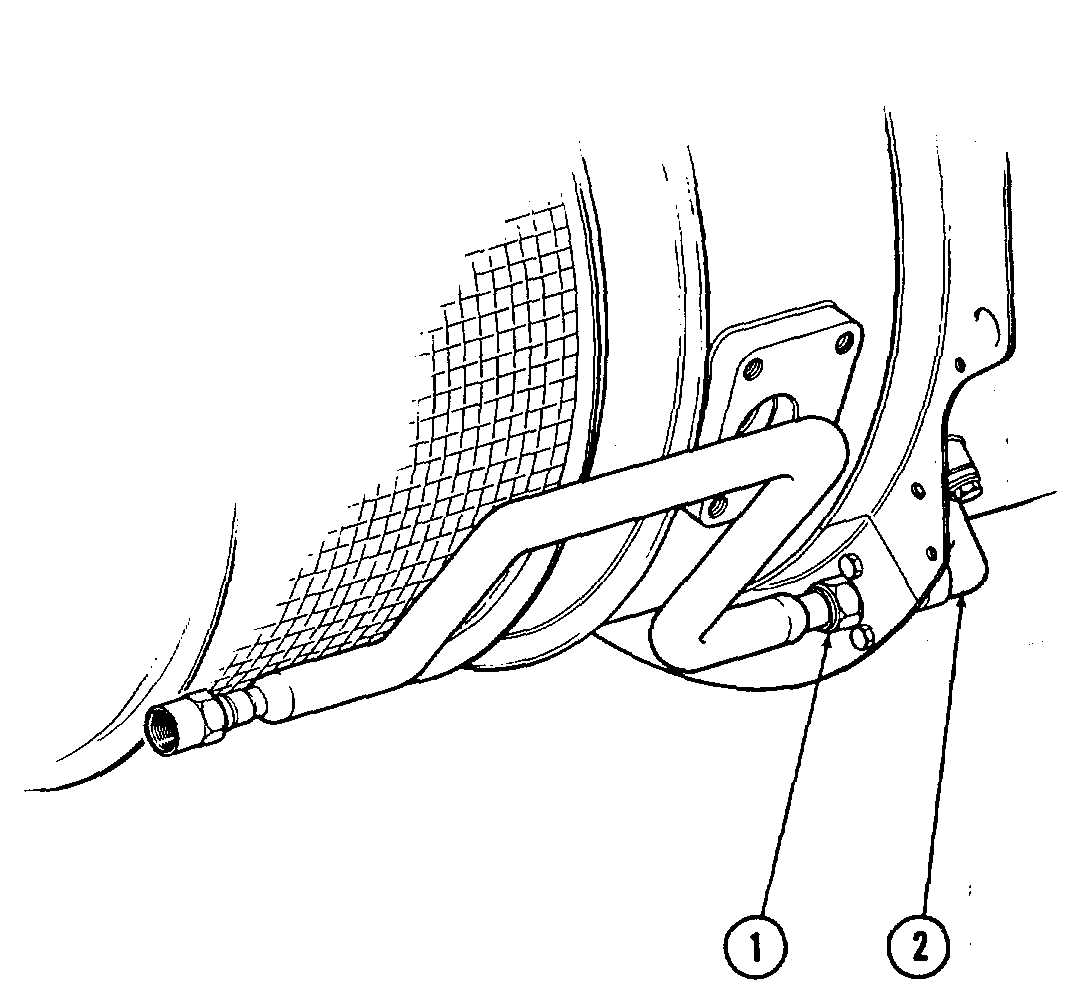

Remove lockwire and disconnect tube nut (1) at

elbow (2).

2.

Install No. 4 union to tube nut (1) and torque tube

nut to 90 to 100 inch-pounds.

WARNING

When

using

compressed

air

for

cleaning, use approved protective

equipment for eyes and face. Do not

use more than 30 psig air pressure.

Do not direct air toward yourself or

another person. Failure to comply

could result in injury, get medical

attention.

3.

Connect an 80 ±

5 psi dry, clean air supply to No.

4 union.

4.

Allow five minute stabilization period, then apply

fluid (E. 38) to entire surface of all connections

throughout pneumatic system to check for leaks.

5.

No leaks are permitted, other than that from

constant bleed hole at base of fuel control unit.

NOTE

Leak testing fluid has a low viscosity

and readily forms an unbroken film

around connections. Any air leaks at

connections

will

produce

distinct

bubbles under film.

6.

Wipe all fluid from connections if no leaks are

detected. If leaks are detected, disconnect faulty

connection and inspect for condition of associated parts.

Install replacement parts as necessary. Retorque and

lockwire.

GO TO NEXT PAGE

10-33