TM 55-2840-254-23

2-65

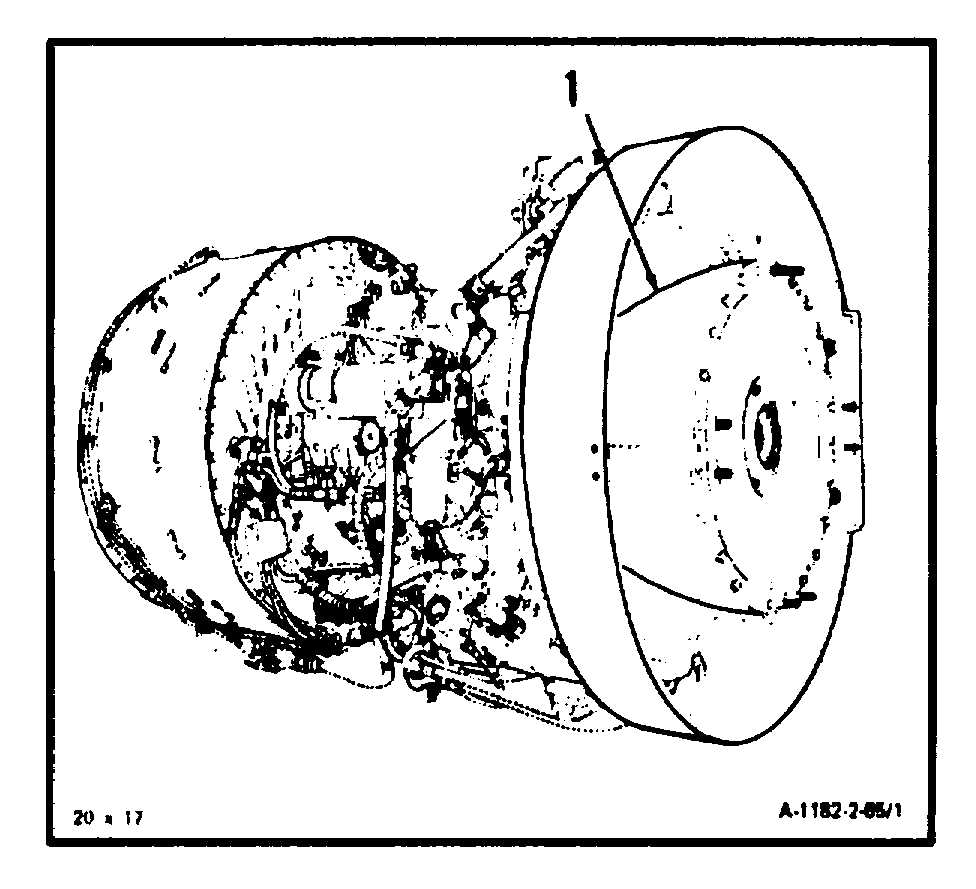

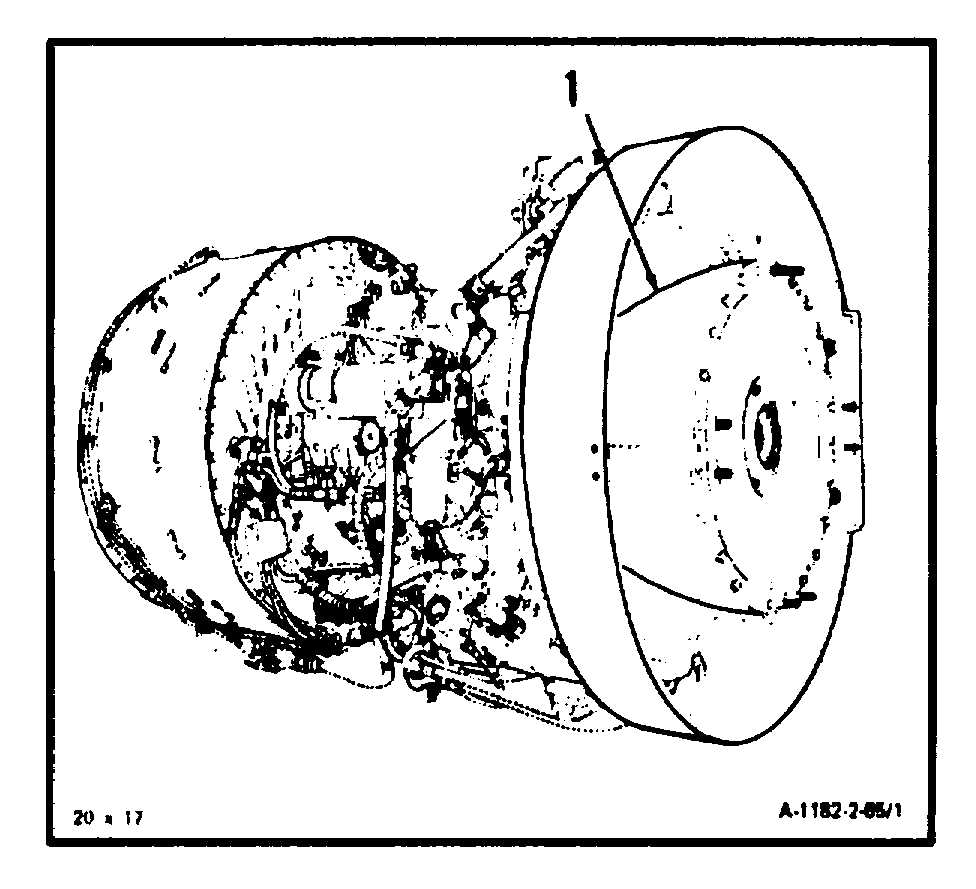

INSPECT AIR INLET HOUSING ASSEMBLY

2-65

INITIAL SETUP

Materials:

Applicable Configurations:

None

All

Personnel Required:

Tools:

68B10 Aircraft Powerplant Repairer

Technical Inspection Tool Kit,

References:

NSN 5180-00-323-5114

Task 1-92

Task 1-119

NOTE

If there is foreign object damage (FOD),

look for more FOD throughout engine.

Perform a FOD inspection (Ref. Task 1-

92).

1.

Inspect air inlet housing assembly (1), using

strong light beam.

a.

There shall be no cracks or FOD.

b.

There shall be no paint damage.

c.

Corrosion shall be treated using touch-up

procedure for magnesium and magnesium

alloys (Ref. Task 1- 119).

(1)

Visually inspect inlet housing for

corrosion.

(2)

A cumulative total of 8 inches of

missing material as measured around

the flange circumference is allowed.

(3)

Individual defects shall not exceed 4

inches in length.

(4)

Individual defects must be separated

by a minimum of 1 inch of unaffected

material.

(5)

If within preceding limits, repair as

outlined in Task 1-119.

(6)

Any number of random minor corroded

areas

not

exceeding

0.25

inch

diameter are acceptable with repair.

(7)

One

single

corroded

area

is

acceptable after repair provided the

area does not exceed 4 inches in

length, 1.375 inches in width and

0.070 inch in depth at deepest point.

(8)

Forward

engine

to

overhaul

if

preceding limits are exceeded.

(9)

If within preceding limits repair as out-

lined in Task 1-119.

GO TO NEXT PAGE

2-498 Change 6