TM 55-4920-328-13

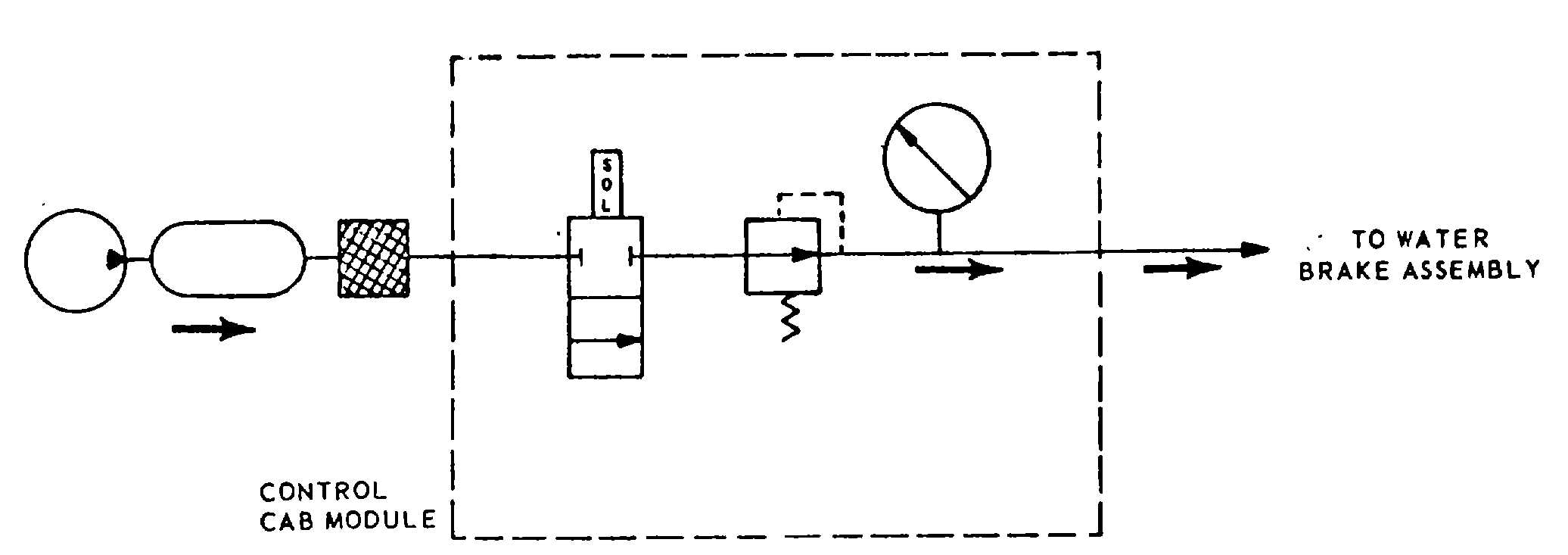

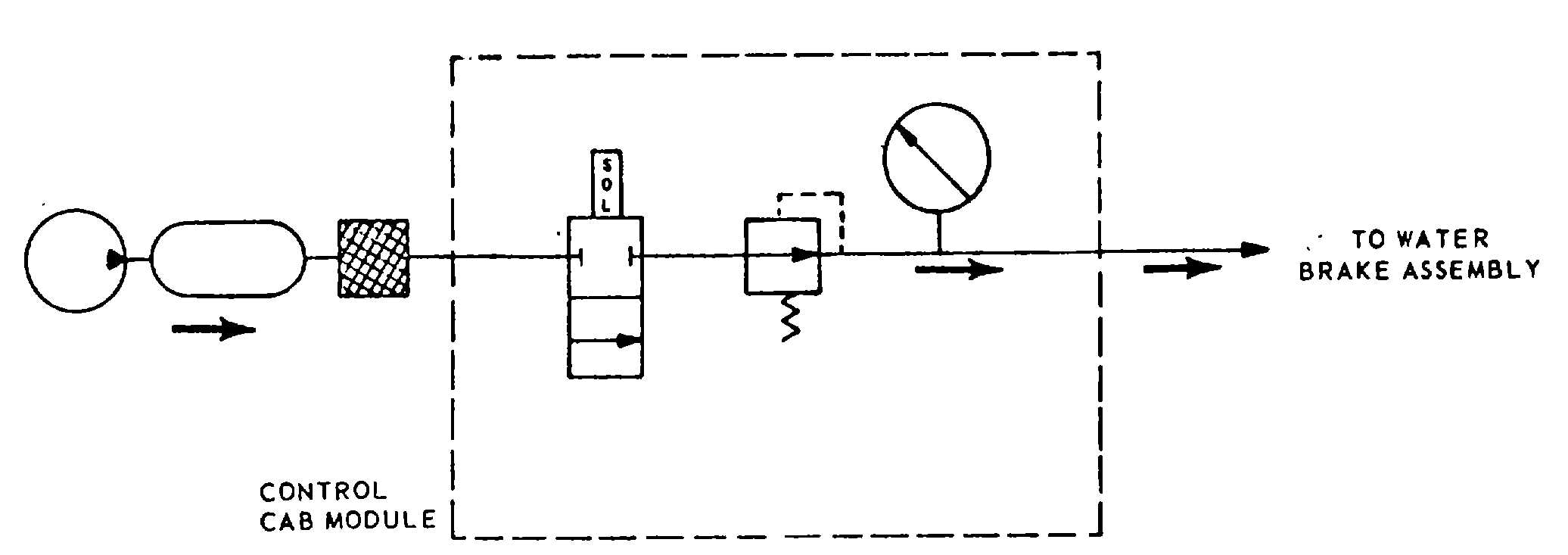

Figure 1-20. Test Trailer Air System Schematic Diagram.

Diagnostic Sub-Module (Unit 1) (13) (e)

Analyzer Sub-Module (Unit 2) (20) (f)

Operator's Sub-Module (Unit 3) (18) (g)

Services Sub-Module (Unit 4) (17) (h)

Control Power Module (Unit 5) (15) (i)

Starter and Contactor Compartment (Unit 6)

(24) (a)

Barrier Strip Junction Box Assembly (Unit 7)

(10) (d)

Left Hand Castle Assembly (Unit 8) (14) (j)

Right Hand Castle Assembly (Unit 9) (16) (k)

Test Trailer Bulkhead Box Assembly (Unit

10) (11) (d)

Generator Fault Indicator Panel (22) (b)

Generator Control Panel (23) (b)

Circuit Breaker Panel Assembly (25) (c)

(a) Starter and contactor compartment (unit

6). The starter and contactor compartment (24, figure 1-

21), located below the rear writing surface assembly in

the control cab module, houses the 4 starters and 2

contactors used in the METS auxiliary systems, except

for the water system. The six units are essentially

heavy-duty relays consisting of two or more sets of

magnetic

contacts,

depending

on

the

service

requirements of each circuit. With the exception of

starter K5 used in the oil preheat circuit and contactor

K6 used in the trickle charger circuit, all units are

provided with thermal element overload protection. The

oil preheat circuit is not provided with a set of overload

contacts; the other five are so equipped. These

overload contacts open on an overload to remove

ground from the relay coil to deenergize the relay and

disable the affected circuit. Refer to chapter 5 for circuit

information on the six starters and contactors. The units

identified by reference designations are used in the

following circuits:

K1 Air System Compressor Motor

K2 Fuel System Pump Motor

K3 Oil System Pump Motor

K4 Portable Oil Unit Pump Motor

K5 Oil System Oil Pre-Heat Unit

K6 Electric Start System Trickle Charger

(b) Generator control and fault indicator

panels. Primary electrical power, provided by the

generator set mounted on the auxiliary trailer assembly,

is remotely controlled within the control cab assembly.

The generator control panel (23, figure 1-21) and

generator fault indicator panel (22) were originally

installed in the diesel engine generator set on the

auxiliary trailer assembly. For operator convenience,

these panels have been relocated within the control cab

assembly. The controls and indicators for each panel

are located and identified in figure 2-8. Refer to TM 5-

6115425-12 for further information.

(c)

Control

cab

circuit

breaker

panel

assembly. The circuit breaker panel assembly (25,

figure 1-21) consists of a rectangular panel assembly

and enclosure which mounts a main ac circuit breaker

and 13 facility service circuit breakers. Contained in the

panel are 5 triple-pole circuit breakers, 3 double-pole

circuit breakers, and 6 single-pole circuit breakers. After

the main ac circuit breaker is energized the 13 auxiliary)

service circuit breakers can be energized as required to

supply power to the control power module switches

contained in Unit 5. The circuit breakers listed below

control the following facility services and systems:

1-25