TM 55-4920-328-13

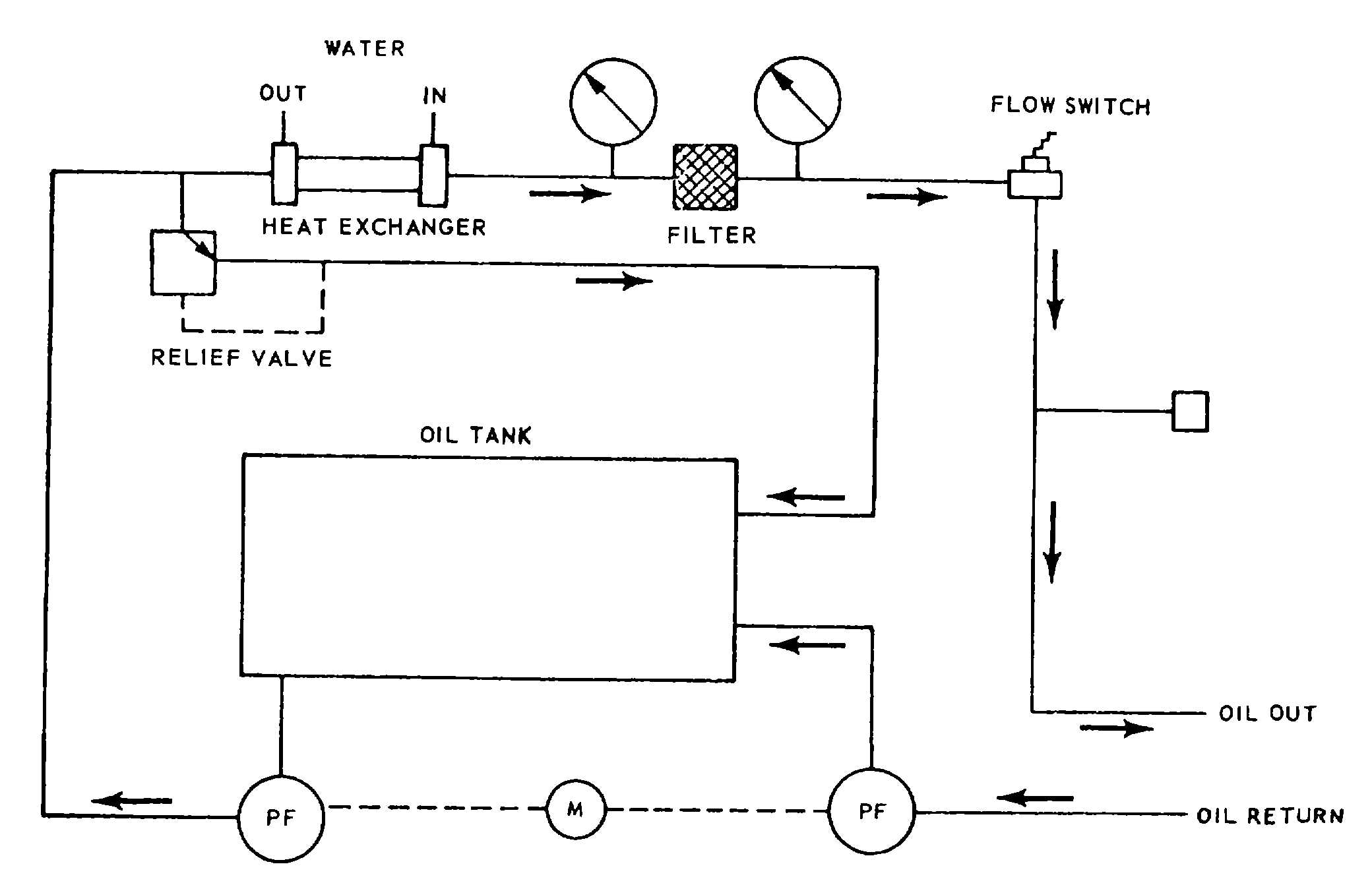

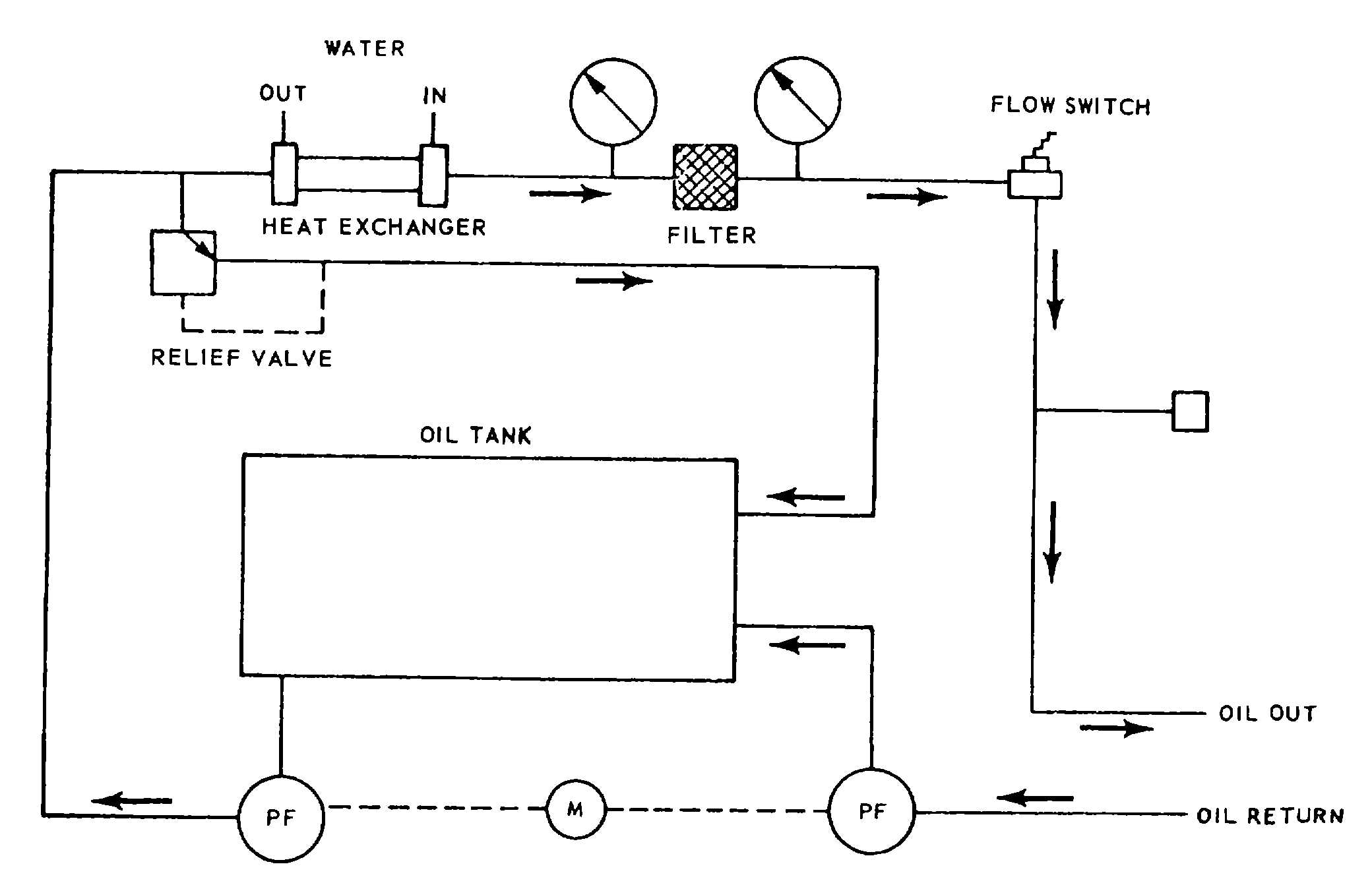

Figure 1-15. Portable Oil Unit Schematic Diagram.

operated by action of the hydraulic servo loops

controlled by two master control units (19, figure 1-21) in

the control cab module. These master control units are

installed on the forward writing surface assembly (12,

figure 1-21).

(b) As shown schematically in figure 1-17,

inlet water under pressure is obtained from the cold well

on the auxiliary trailer through a 30-foot long hose

assembly. Four supply and three return branches are

connected to the system downstream from the strainer.

The water brake assembly water-in branch is routed

through the hydraulically-controlled inlet control valve

and terminates in a quick-disconnect fitting. A second

branch is routed through the filter and in-line flow

switches and terminates at a quick-disconnect fitting to

which a water brake bearing supply hose, assembly is

connected prior to a test. The water system supply line

then divides to branch through the oil system heat

exchanger and oil system temperature regulating valve,

and also flows through the heat exchanger in the

portable oil unit. These branches and the water brake

assembly water out branch converge at the return leg of

the system which terminates at a quick-disconnect

fitting. A second 30-foot long hose assembly transfers

the heated water from the two heat exchangers and

from the water brake assembly to the auxiliary trailer hot

water well. The flow switch to be used depends on the

particular engine being tested One of the two normally-

closed spat flow switches opens on increasing flow of

4.0 to 4.4 gpm. The other flow switch opens on

increasing flow of 0.9 to 1.3 gpm. Closure of the flow

switch during water system operation completes a circuit

to illuminate the WATER BRAKE BRG H2O indicator

DS5 (21, figure 1-25) on the ALARM DISPLAY section

of the upper panel assembly on the services sub-

module. This action simultaneously causes the audible

alarm to sound to alert the test technician of a low flow

condition. Controls for operation of the water system

are depicted in figure 1-26 and are located on the No. 1

power control panel assembly.

(10) Test trailer air system.

(a) The test trailer air system (figure 1-18)

provides pressurized air to the water brake assembly

when testing certain engines, and to the PI air bellows

connection when a T53 engine is to be

1-20 Change 3