TM 1-1500-204-23-1

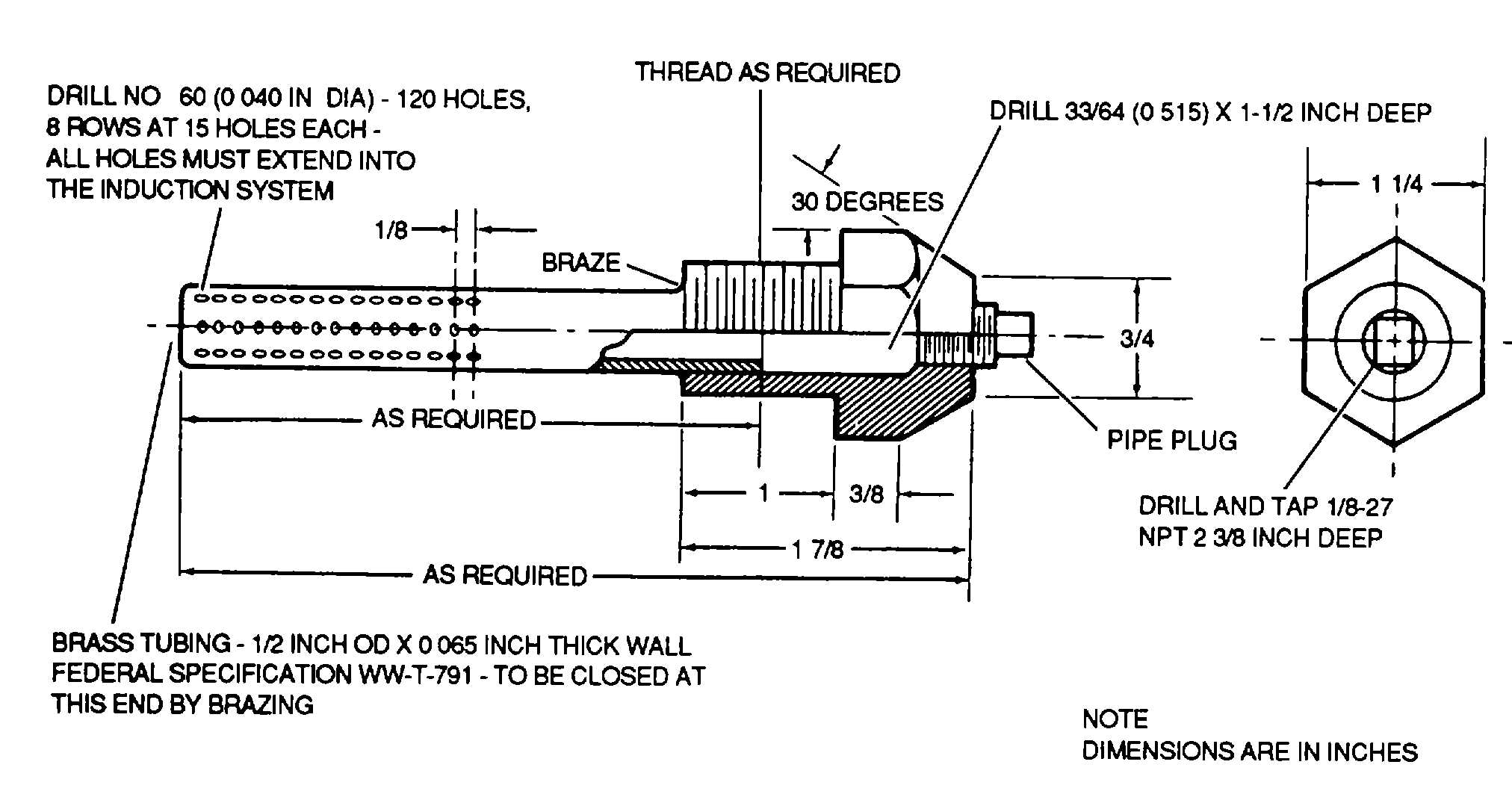

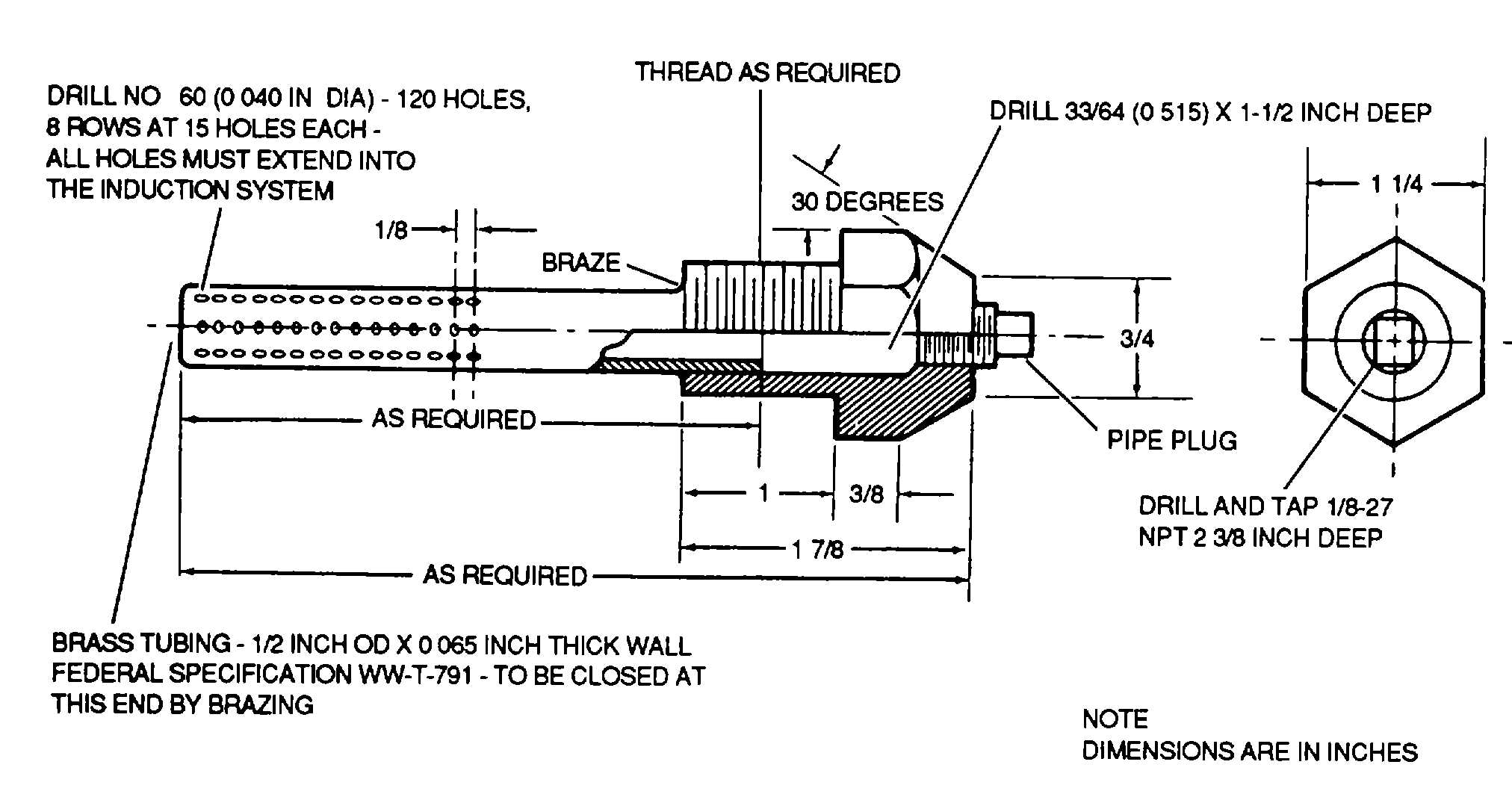

Figure 7-24. Discharge Nozzle for Corrosion Preventive Mixture

(4)

Thermostatically

control

corrosion

preventive supply tank to maintain corrosion preventive,

MIL-C-6529, Type II at a temperature of 221 to 250 °F

(105 to 121 C).

(5)

Connect an air pressure line providing 60

to 80 psi dry compressed air to the tank Mixture capacity

of the tank will be as follows:

· One quart for engines up to 1340 cubic inch

displacement.

· Two quarts for engines up to and including

2000 cubic inch displacement.

· Three quarts for engines up to 3350 cubic

inch displacement.

(6)

Make final engine run with oil system

serviced with corrosion preventive as follows:

CAUTION

At no time will engine be operated in

excess of 1500 rpm while the oil

system Is serviced with corrosion

preventive mixture. Damage may

otherwise result.

(a)

Operate engine on service fuel for a

period of 15 minutes.

(b)

With engine operating at 1500 rpm,

release corrosion preventive mixture through nozzle. As

soon as white smoke appears at upper cylinder exhaust

stacks for radial engines and at all stacks for opposed

engines, move mixture control to IDLE CUT-OFF

position and allow engine to stop. Continue aspiration of

mixture until engine ceases to fire

(7)

Drain

preservation

mixture

from

oil

system while engine Is warm, exercising care to keep

corrosion preventive mixture clean for future use.

(8)

Clean filter and screen and coat with

corrosion preventive mixture and reinstall.

(9)

When rocker box covers have been

removed for any reason, rocker box interior shall be

treated as follows:

(a)

Drain oil from each rocker box from

which cover IS removed

(b)

Spray-coat

rocker

arms,

valve

stems, springs, push rods, rocker box covers, and rocker

boxes with corrosion preventive, ML-C-16173, Grade 2.

7-41