TM 1-1500-204-23-1

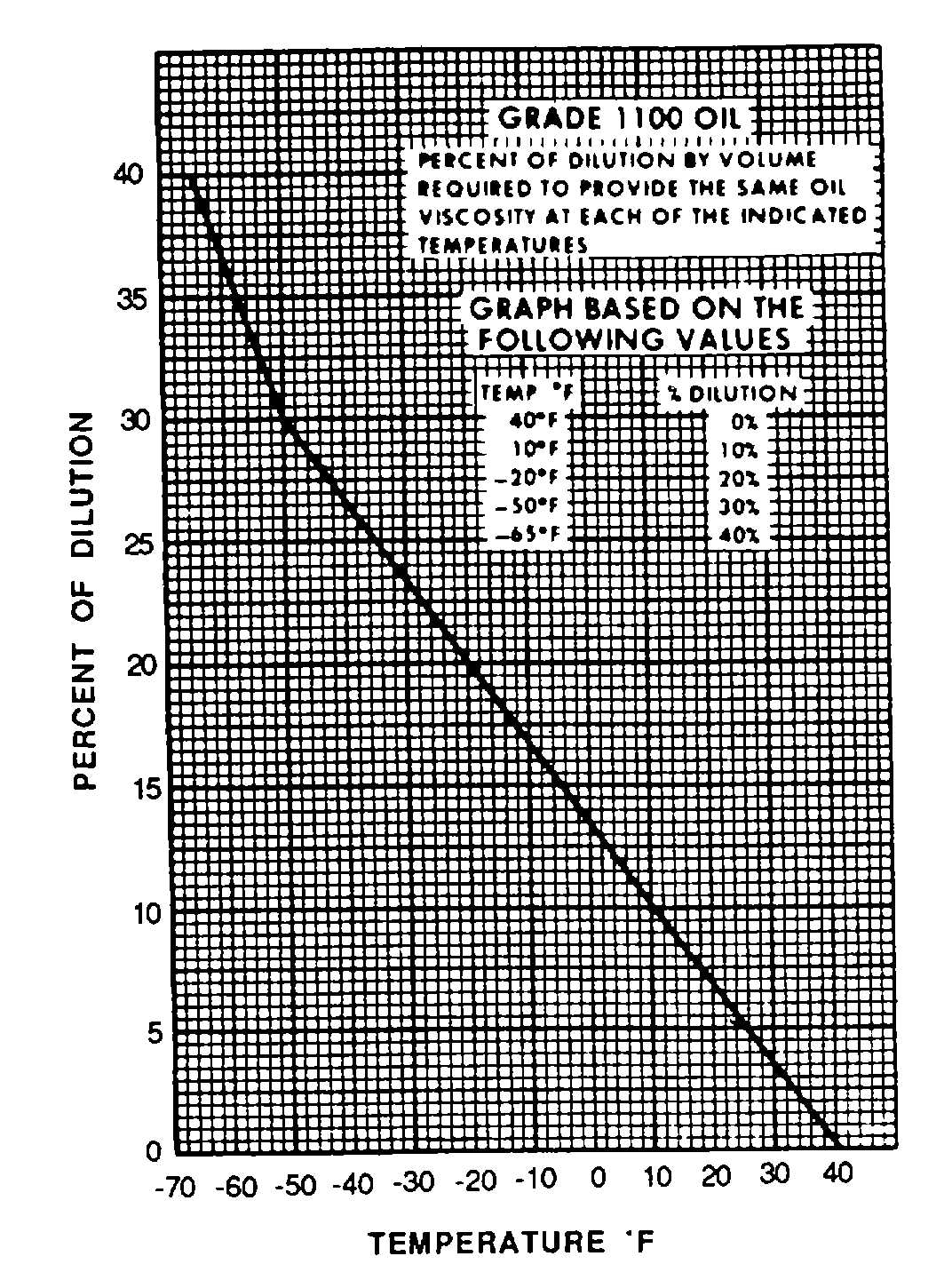

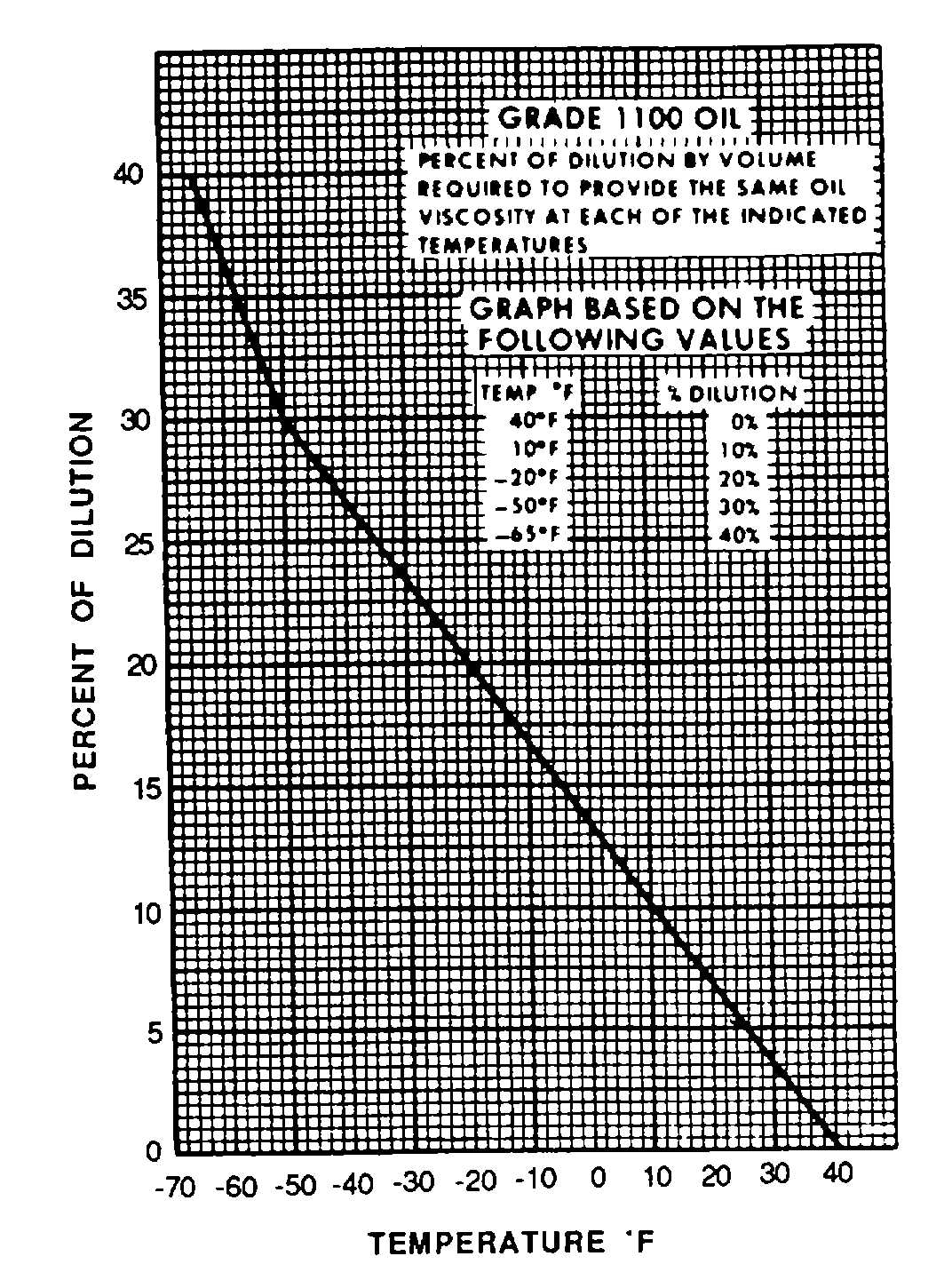

Figure 7-25. Percent Dilution Versus Temperature for Grade 1100 Oil

(c) Connect preoiler to preoiling fitting.

(d) Rotate engine with starter and commence

preoiling until oil is flowing freely from sump plug holes

and pressure Is indicated on oil pressure gauge in

aircraft.

(e) Cease operation and replace sump plugs.

(f) Remove rocker box covers from number one

cylinder or both top covers on double row engines and

continue preoiling until oil is obtained from all rocker

arms that have been removed.

(g) Disconnect preoiler and reinstall all parts

removed.

NOTE

Newly installed engines will be given

an initial start as soon as possible,

but not later than 4 hours after

preoiling has been accomplished.

When any period of time in excess of

4 hours has elapsed since engine

was preoiled, complete preoiling

procedure

shall

again

be

accomplished

before

attempting

initial start of engine.

b Depreservation Run. The depreservation run

eliminates the necessity of removing or draining Intake

pipes prior to installation of engine in the aircraft.

Perform

depreservation

run

using

the

following

procedures:

7-46