TM 1-1500-204-23-1

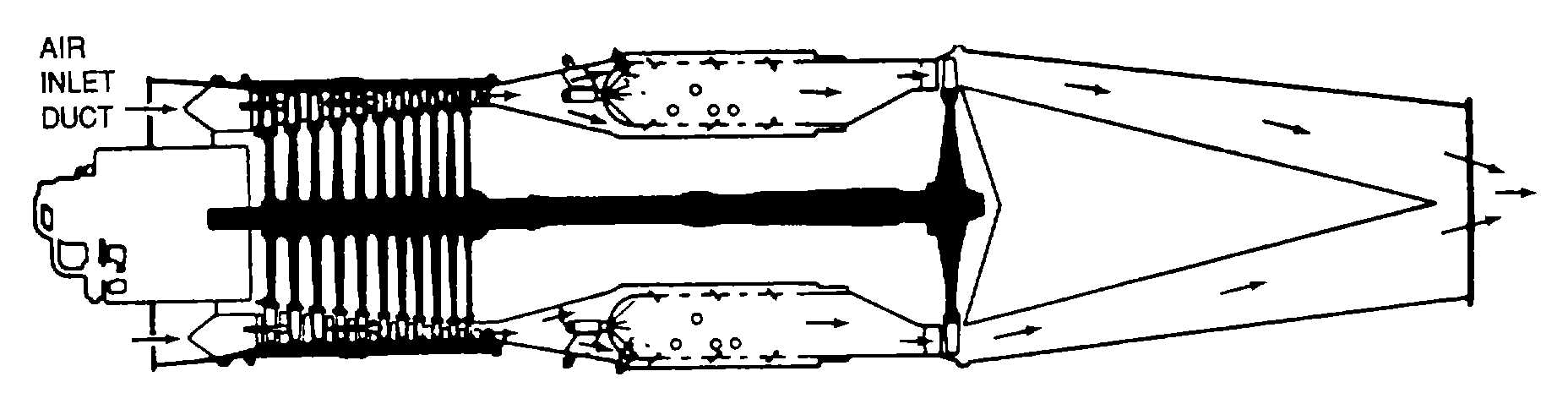

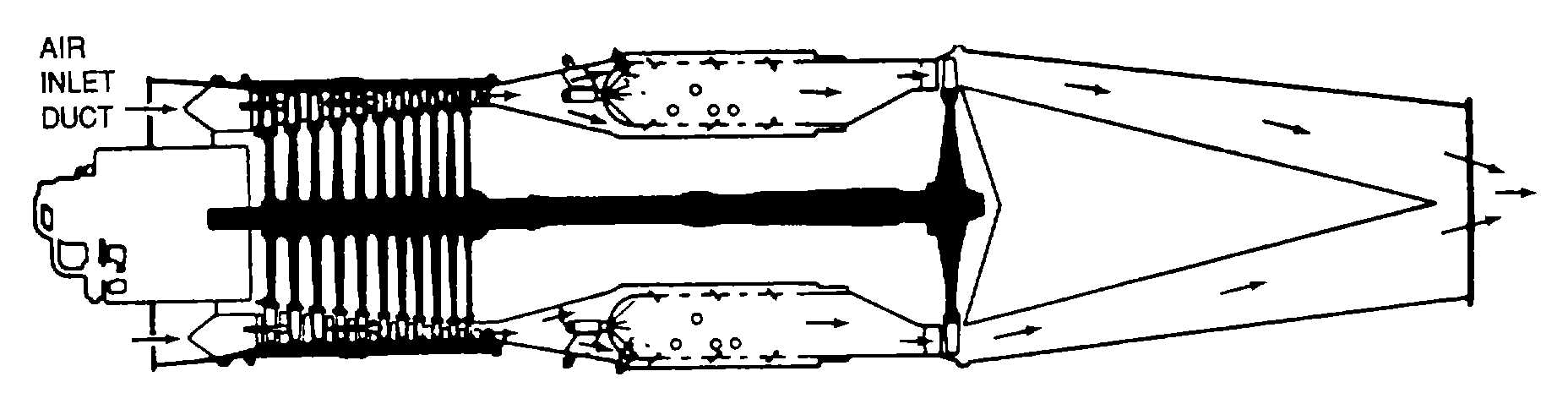

Figure 8-3. Single Entrance Inlet Duct (Axial-Flow Engine)

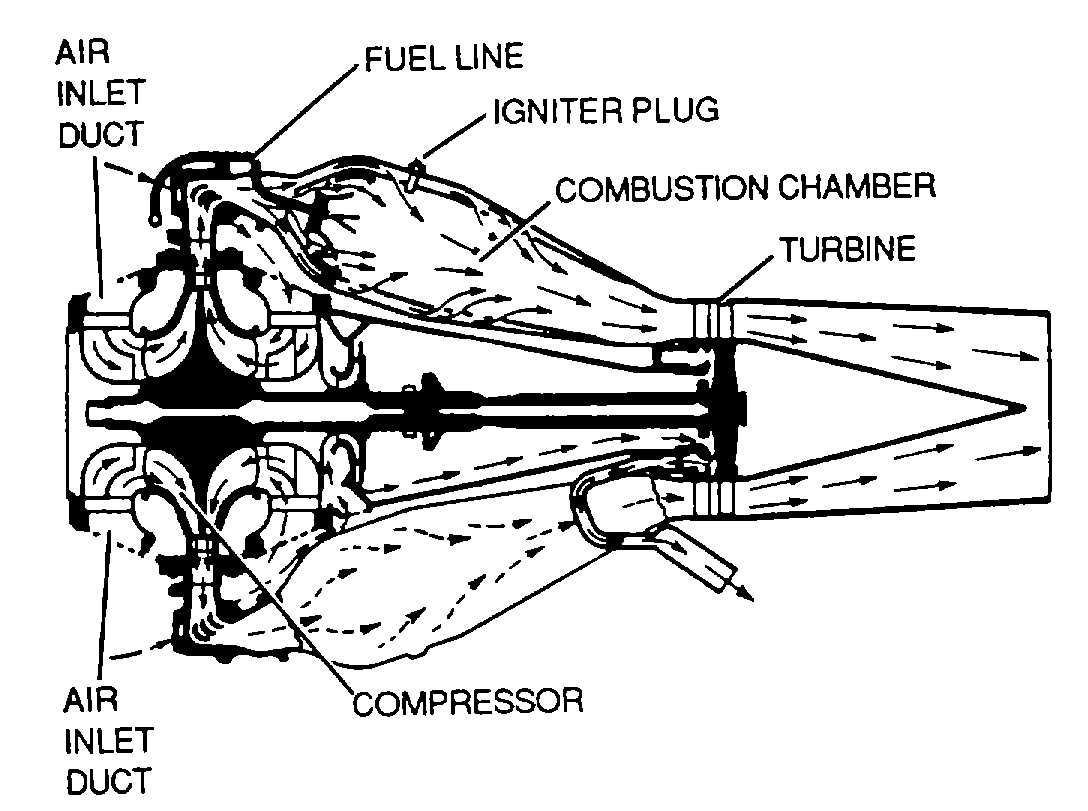

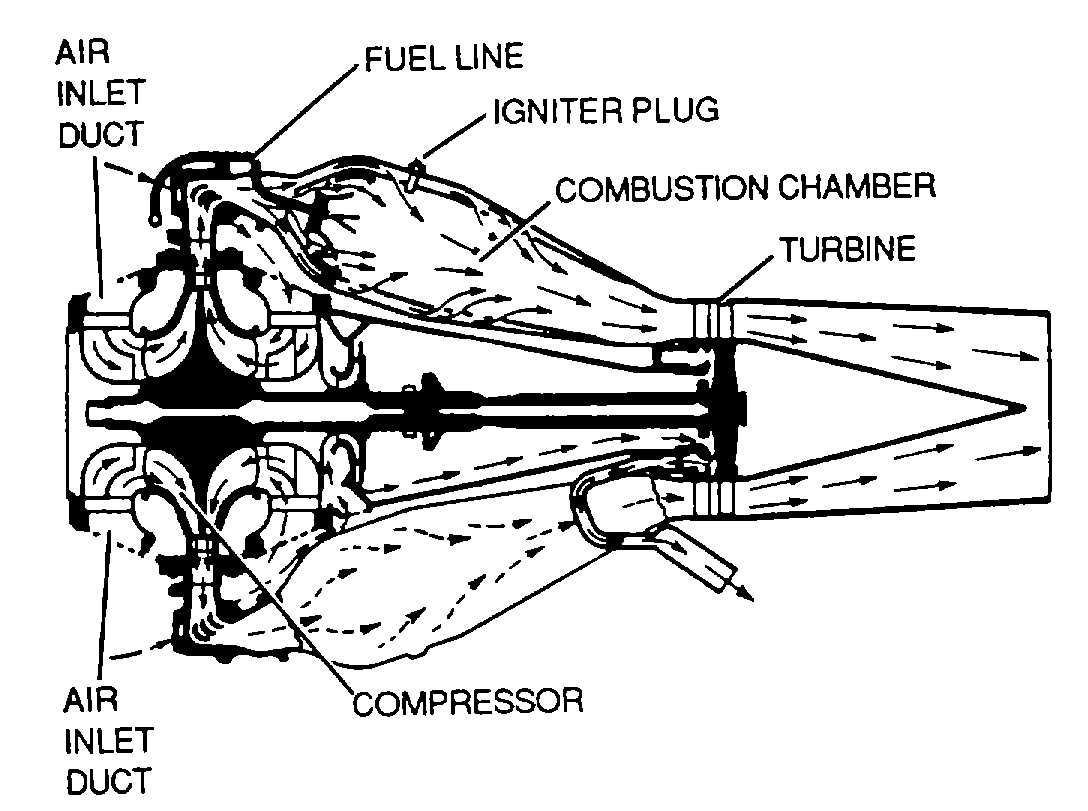

Figure 8-4. Divided Entrance Inlet Duct

(Centrifugal-Flow Engine)

b Particle Separators. Particle separators, as shown

in figure 8-5, prevent foreign particles from entering the

compressor section of turbine engines. Air enters the

engine through the swirl frame. Swirl vanes direct the

air into a rotating or swirling pattern. Sand, dust, and

other foreign objects are separated by centrifugal action.

These objects are carried to the outer section of the

main frame and into the scroll case. Particles are drawn

from the scroll case by the blower and are blown out the

aircraft discharge duct. The relatively clean air that

remains after particles are separated is carried to the

front frame deswirl vanes, which straighten the air flow

before it enters the compressor inlet.

c. Compressor Section. The compressor section of a

turbine engine has many functions. Its primary

functions is to supply air in sufficient quantity to satisfy

the requirements of the combustion burners. The

compressor must increase the pressure of the mass of

air received from the air inlet duct and then discharge it

to the burners in the quantity and at the pressure

required. A secondary function of the compressor is to

supply bleed-air for various purposes In the engine and

aircraft.

(1) Centrifugal-flow compressor. The centrifugal-

flow compressor consists basically of an Impeller (rotor),

a diffuser (stator), and a compressor manifold, as shown

In figure 8-6. The compressor achieves its purpose by

picking up the entering air and accelerating it outwardly

by centrifugal action.

(2) Axial-flow compressor. In the axial-flow engine,

the air is compressed while continuing in its original

direction of flow, thus avoiding the energy loss caused

by turns. From inlet to exit the air flows along an axial

path and is compressed at a ratio of approximately

1.25.1 per stage. The axial-flow compressor has two

main elements, a rotor and a stator, as shown in figure

8-7. The rotor has blades fixed on a spindle. These

blades Impel air rearward in the same manner as a

propeller because of their angle and airfoil contour. The

rotor, turning at high speed, takes In air at the

compressor inlet and impels it through a series of

stages. The action of the rotor increases the

compression of the air at each stage and accelerates it

rearward through several stages With this increased

velocity, energy is transferred from the compressor to

the air in the form of velocity energy. The stator blades

act as diffusers at each stage, partially converting high

velocity to pressure. Each consecutive pair of rotor and

stator blades constitutes a pressure stage. The number

of rows of blades (stages) is determined by the amount

of air and total pressure rise required. The greater the

number of stages, the higher the compression ration.

8-4