TM 1-1500-204-23-1

6

Set calibrated scale until zero mark

on scale and scribe on pointer are aligned.

7

Move pointer back to top of slot or

until it contacts pivot arm.

8

Turn

crankshaft

in

direction

opposite normal rotation until pivot arm returns to top of

slot.

9

Recheck zero mark of calibrated

scale against reference mark on slide pointer.

10

Move slide pointer to top of slot or

until it contacts pivot arm.

11

Rotate crankshaft In direction of

rotation. Movement of slide pointer by the pivot arm will

Indicate crankshaft position In relation to true top dead

center on the calibrated scale.

(e)

Alternate methods of locating leaky

intake exhaust valves. Alternate methods of locating

leaky intake and exhaust valves are listed In the following

paragraphs.

1

Engine run test. Prior to stopping

engine, run it up to 1000 rpm and move mixture control to

IDLE CUT-OFF. The engine will turn over six or more

revolutions after combustion ceases. A very slight

burning of an exhaust valve will be evidenced by a

pronounced slush from the affected cylinder This sound

occurs each second revolution of the engine.

2

Wheeze test Perform wheeze test

for locating leaky intake and exhaust valves by pulling

piston to top dead center, locate faulty valve by listening

for noise in exhaust collector or Intake duct which

indicates air leaking past respective valve.

3

Compressed

air

test

Admit

compressed air into cylinder through spark plug hole

Restrain piston at top of dead center Locate leaking valve

by listening for noise in exhaust collector and intake duct.

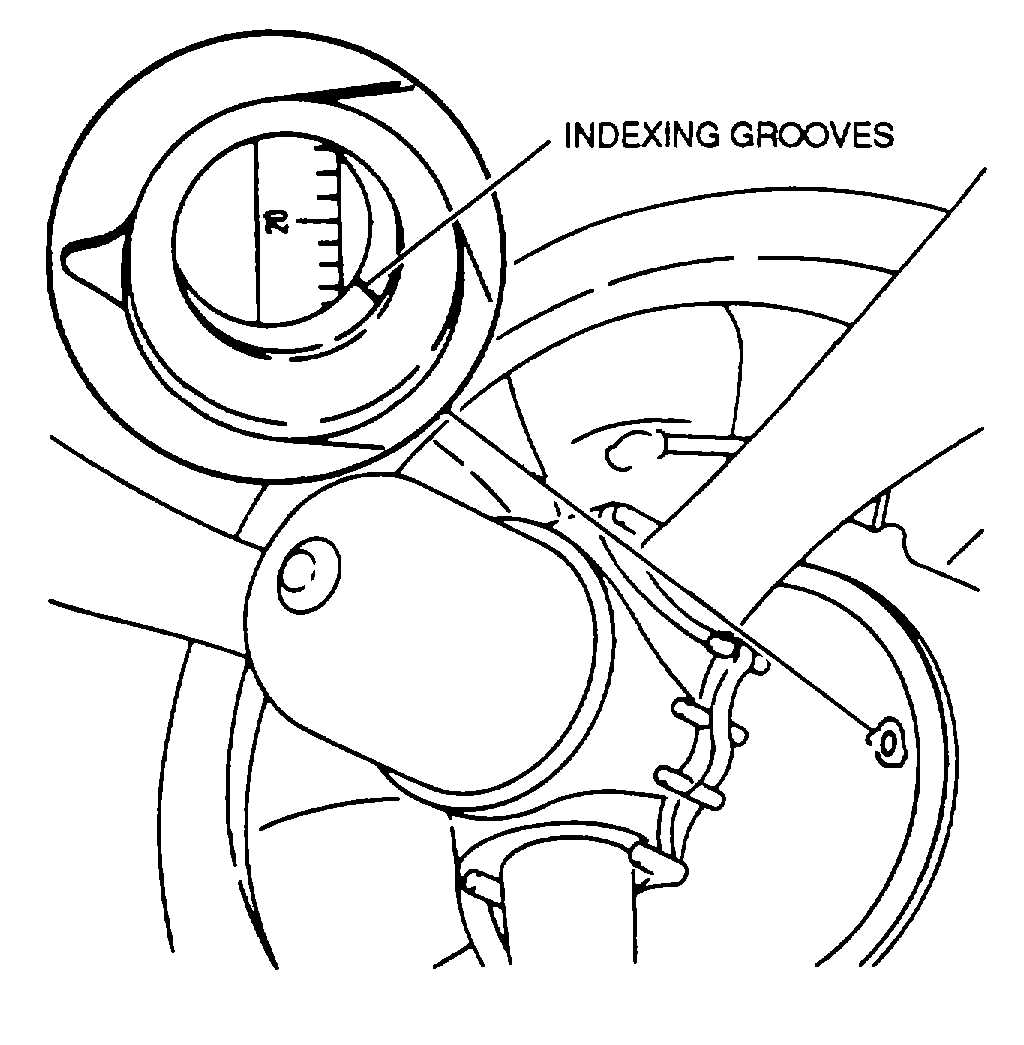

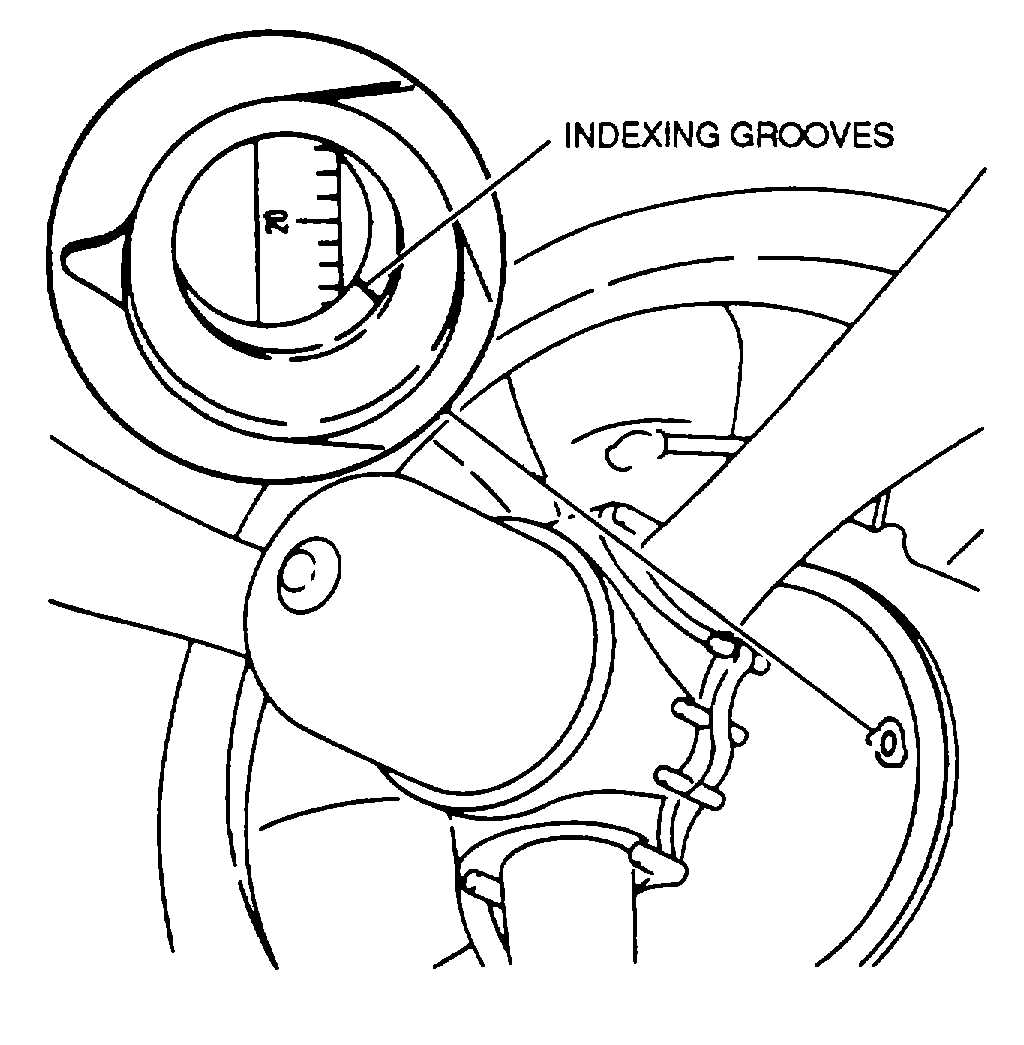

(f)

Built-m timing marks. Some engines

have reference timing marks built into the engine, as

shown in figure 7-17. Engines without a propeller

reduction gear will have the timing mark, a scribe mark or

a pin, on the propeller shaft and a corresponding

reference mark on the surface of the nose section next to

the shaft. Refer to the applicable maintenance manual

for location of such marks.

NOTE

When using timing marks to position

the crankshaft, sight straight across

the stationary pointer or mark on the

nose section to the other mark. Any

angle incurred in sighting will cause

error when positioning the crankshaft.

h.

Accessories. Accessory units such as fuel

pumps,

vacuum

pumps,

oil

pumps,

generators,

alternators, magnetos, starters, filters, superchargers, and

turbochargers are attached to the engine. Refer to the

applicable maintenance manual for specific maintenance

procedures

i.

Ignition System. The ignition system must deliver

a high-tension spark to each cylinder of the engine in

firing order at a predetermined number of degrees ahead

of true top dead center. Voltage output of the system

must be such that the spark will jump the spark plug gap

under all operating conditions with no tendency for

electrical leaks. Timing and replacement of parts make

up most of the Ignition system maintenance.

(1) Magneto system. The magneto, a special type of

engine-driven ac generator, uses a permanent magnetic

source. The magneto develops the high voltage which

forces a spark to jump across the spark

Figure 7-17. Built-In Timing Marks

7-17