TM 1-1500-204-23-1

uniform. Temperature changes affect air-cooled

engines to a greater extent than other engines, and there

must be sufficient valve clearance to prevent valve from

holding open when extreme cold is encountered, since

holding open will make cold weather starting extremely

difficult. Inadequate clearance or excessive clearance is

conducive to valve failure; therefore, proper settings are

essential to engine operation.

(a)

Measuring

and

adjusting

valve

clearance When rough engine operation, backfiring, loss

of compression, hard starting, or any malfunction which

can be attributed to improper operation or clearance of

valves occurs, valve clearance shall be measured and

adjusted, using the following procedures

1

Measure

and

adjust

valve

clearance

in

accordance

with

specific

instructions

contained In applicable engine maintenance manual.

2

Locate top dead center piston

position.

3

Use feeler gauge (shaped so that

end of gauge can be slipped in a straight line between

valve and rocker arm roller or adjusting screw) specified

in tools section of maintenance manual.

NOTE

Do not use excessive force to insert

gauge

between

valve

stem

and

adjustment screw or rocker arm roller.

4

Adjust valve clearances found to be

out of adjustment according to specific procedures in

engine maintenance manual.

(b)

Reclamation

and

disposition

of

sodium-filled valves. The reclamation procedure for

sodium-filled valves consists primarily of rebuilding the

facing of exhaust valves and repairing the stems

WARNING

Do not attempt to mutilate sodium-

filled valves. The metallic sodium

used

in

these

valves,

when

contracting moisture, gives off highly

flammable hydrogen gas, and when

brought into contact with the skin

often results in severe personal injury.

1

Sodium-filled

valves

definitely

determined to be nonrepairable as a result of cracked or

broken stems shall be processed for disposition In

accordance with procedures established by Part 3,

Chapter XV, DOD directive 4160 21M. Disposal of these

nonrepairable valves shall be affected by one of the

following methods.

Burial, at least 30 inches below ground level, in

a select location where future excavation is

unlikely.

By dumping at sea.

2

Values determined to be suitable

for reclamation shall be prepared for shipment in

accordance with provisions of AR 746-1.

(c)

Establishing crankshaft position using

top center indicator and protractor. The proper crankshaft

position must be established prior to checking or setting

valves using the following procedures.

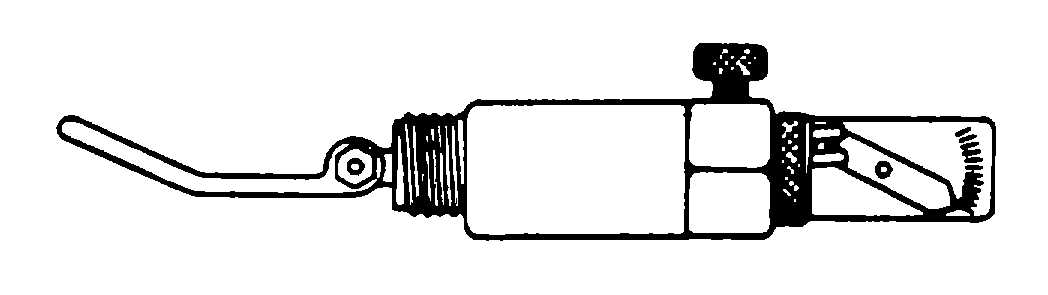

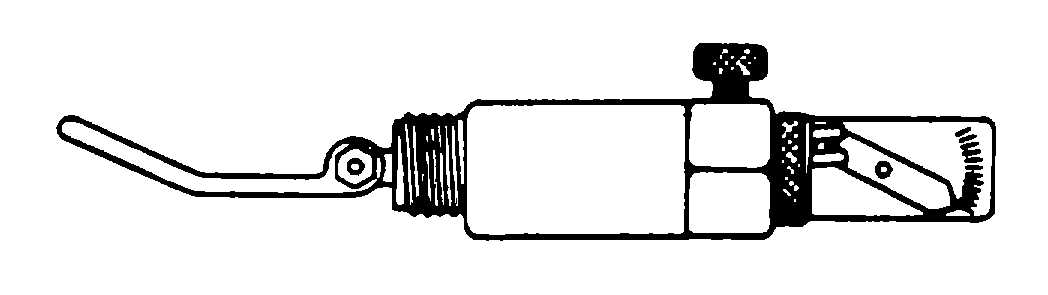

1

Determine

ratio

of

top

center

indicator, as shown in figure 7-15, pointer travel to

crankshaft travel.

2

Install Indicator in either spark plug

hole of number one cylinder.

3

Adjust arm of indicator so that full

scale deflections will be obtained as piston moves through

its full stroke.

4

Install

protractor

and

pointer

specified in engine maintenance manual on one of engine

accessory drive pads.

5

Rotate

crankshaft

in

normal

direction of rotation until piston is coming up on

compression stroke.

Figure 7-15. Top Center Indicator

7-15