TM 1-1500-204-23-2

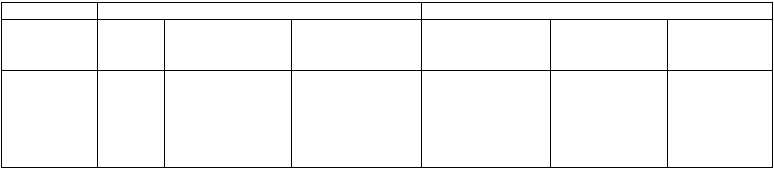

Table 4-27. Hose Cutoff Factors, MIL-H-38360 Hose (In Inches)

MS swivel or fittings

MS flange fittings

Size

A

B

C

A

B

C

ST

45 degrees

90 degrees

ST

45 degrees

90 degrees

—4

.92

2.06

1.69

1.15

2.19

1.69

—6

1.04

32.35

1.92

1.26

2.50

1.92

—8

1.16

2.61

2.10

1.46

2.81

2.10

—10

1.21

2.74

2.26

1.50

2.94

2.26

—12

1.27

3.06

2.40

1.71

3.35

2.40

—16

1.33

3.84

2.74

1.92

3.76

2.74

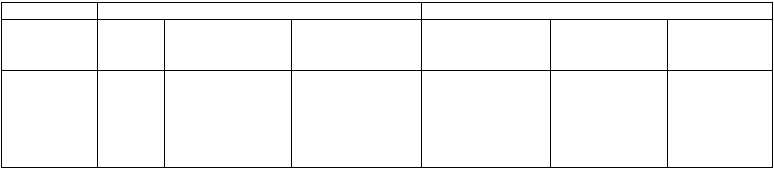

Table 4-28. Proof Test Pressures, High-Pressures Teflon Hose Assemblies

Swivel end

Hose size

fittings

—3

6000 PSI

—4

6000 PSI

—5

6000 PSI

—6

6000 PSI

—8

6000 PSI

—10

6000 PSI

—12

6000 PSI

—16

6000 PSI

—20

6000 PSI

(b)

Inspect. Inspect hose assembly internally for cut or bulged inner tube, obstructions and

cleanliness. Examine hose assemblies and fittings for hose push-out. Inspect for proper gap between nut and socket or

hex and socket Nuts should swivel freely.

(c)

Proof pressure test. All hose assemblies shall be pressure tested to the values specified in

Table 4-28 for not less than 30 seconds and not more than 5 minutes. Test with hydraulic oil conforming to MIL-H-5606

for tests conducted at room temperature. Any evidence of leakage from hose or fittings or any other evidence of

malfunction shall constitute failure.

NOTE

Inspect all hose with fire sleeving after proof testing for fluid contamination. Contaminated sleeving will be

replaced.

(8)

Installation of hose assembly. Refer to paragraph 4-51 (13). Refer to table 4-29 for support clamp

sizes.

(9)

Storage of hose and assemblies. Refer to paragraph 4-5i (14).

(10)

Hose disposition. Refer to paragraph 4-51 (15).

(11)

DELETE

k.

Self-Sealing. Hose for Aromatic Fuel MIL-H-7061. Instructions for the use of self-sealing hose are contained

in the following paragraphs.

4-72 Change 2