TM 1-1500-204-23-2

coolant hose when installation is made, however, oil only should be used on hydraulic and pneumatic hose.

b.

Hose Installation. Install hose so that it will not be subject to twisting under any condition of operation, and

there will be no tendency for the connecting fittings to loosen. When replacing hose in hydraulic, fuel oil, alcohol, water

Injection, and pneumatic systems, hose installed should be a duplicate of hose removed as to length, outside diameter,

Inside diameter, material, type, and contour unless otherwise directed.

c.

Bends When bends are required in Installing hose in fluid systems, the radii shown in table 4-32 should be

the minimum radii maintained at times for fuel, oil, and coolant systems. Table 4-32 also shows minimum bend radii for

hydraulic and pneumatic systems. A radius larger than the minimum allowed is preferred.

d.

Hose Restriction. When hose is installed through holes In brackets, or when supporting clips are used, there

must be no reduction in diameter of hose. If this condition is present, flow will be reduced and damaged to hose may

occur.

e.

Support. Support hose at least every 24 inches. Closer supports are preferred Support flexible lines so that

they will not cause deflection of rigid connecting lines Flexible hose between two rigid connections

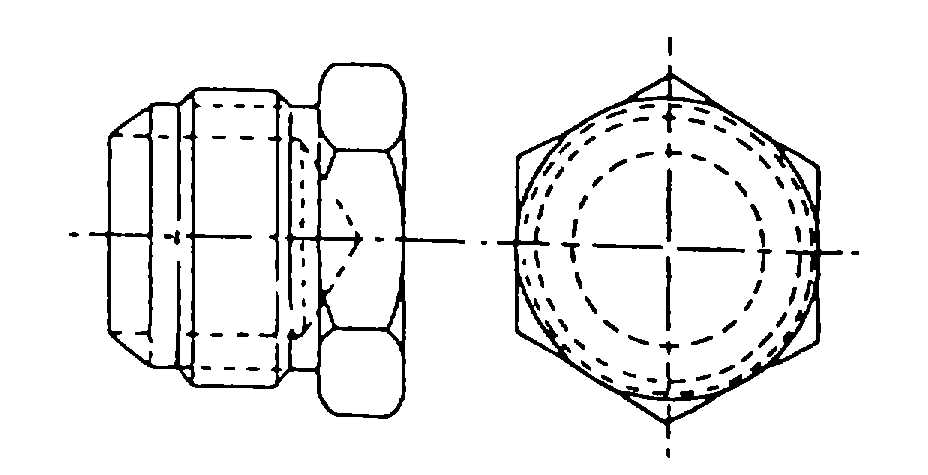

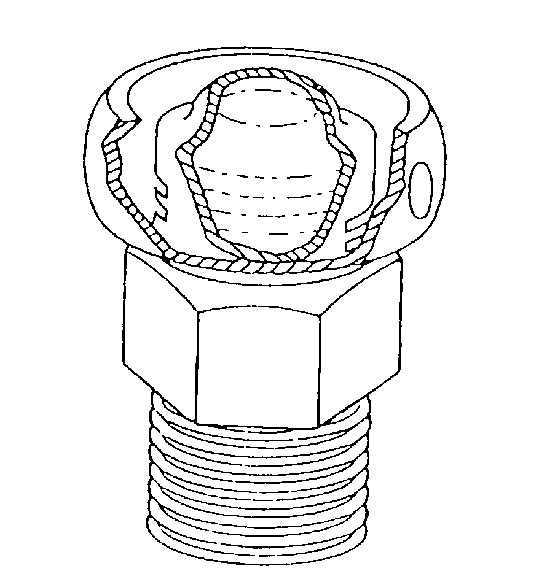

Figure 4-52. Steel Protective Dust Plug and Moisture Seal

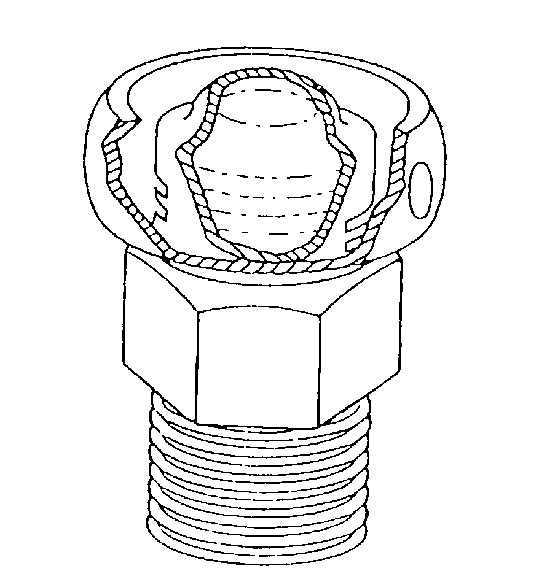

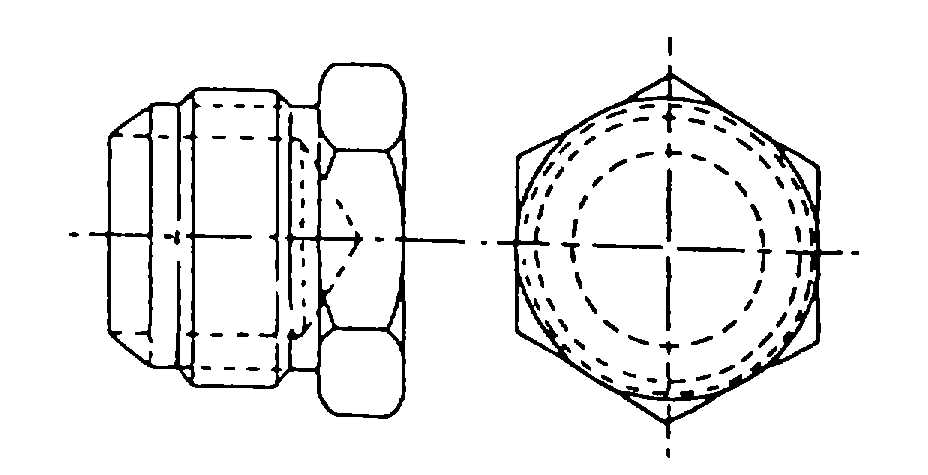

Figure 4-53. Steel Protective Dust Cap

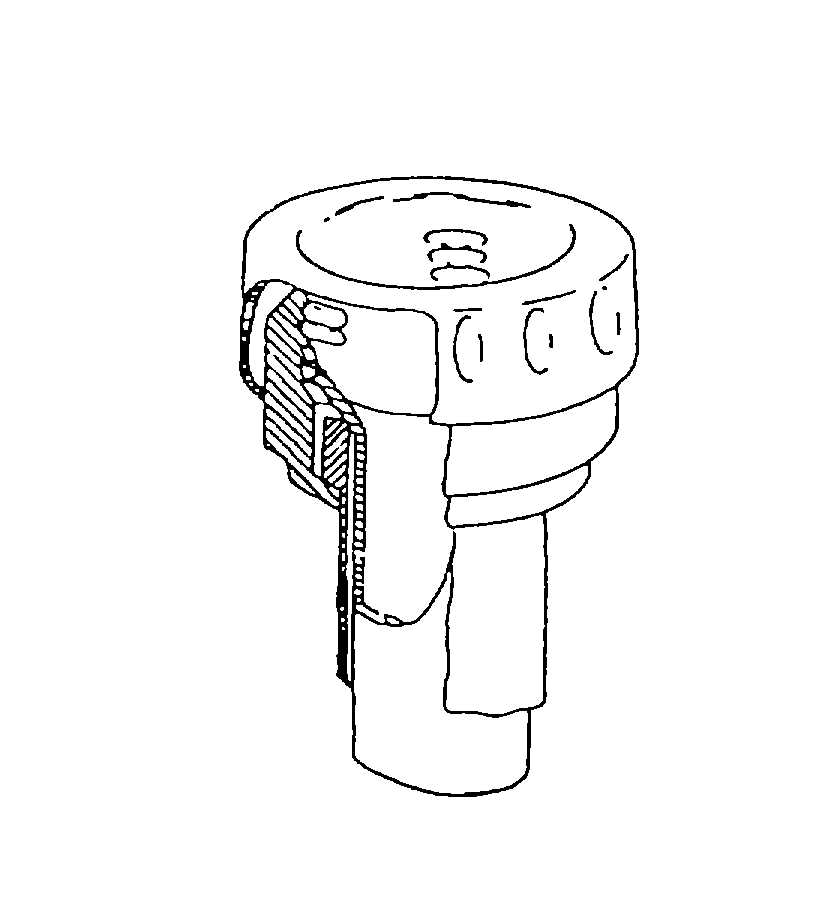

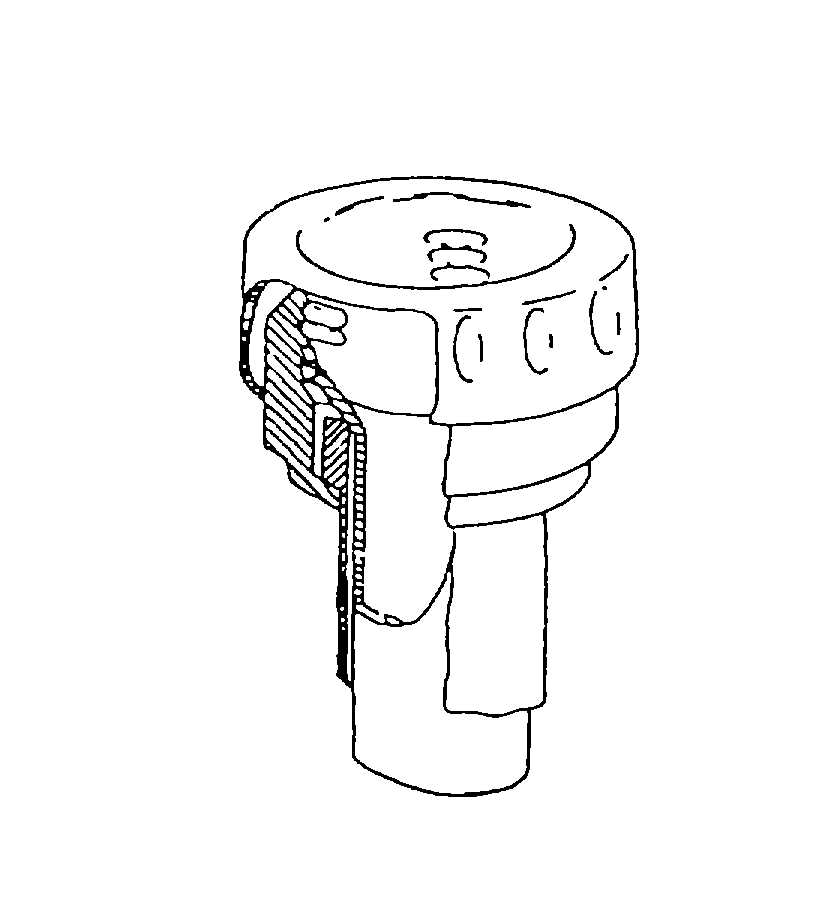

Figure 4-54. Aluminum Protective Dust Plug and Moisture Seal

4-76