TM 1-1500-204-23-2

4-9. Swaged Tubing Repairs. The basic element of the repair technique is

the Permaswage fitting, which is mechanically swaged onto the tube by a

hydraulically operated tool. Fittings are available in configurations

including permanent unions and shapes (elbows, tees, and crosses), flared,

flareless and lip seal separable sleeves and unions, as well as

combinations of permanent and threaded fittings See figure 4-78. This

repair technique is only applicable to tubing assemblies not exceeding the

material-line-size-operating pressure requirements of table 4-35. The

repair method is not to be used with annealed corrosion-resistant steel or

5052 aluminum tubing.

CAUTION

Permaswage

fittings

are

manufactured

using

21-6-9

corrosion-resistant steel and are compatible only with those

tubing materials specified In table 4-35. The use of 21-6-9

Permaswage fittings with tubing material other than that

specified in table 4-35 will result in an unacceptable (or

unsafe) repair and is prohibited.

a.

Application. Four basic types of tube assembly failure lend

themselves to permanent repair using Permaswage techniques. The

failure modes and the recommended repair method for each are described

in figure 4-79.

b. Technique. The Permaswage technique for tubing repair involves

cutting, deburring, tube end preparation, and swaging and gauging

operations. The following general procedure should be used when the

location of the tube ends must be maintained when marking any of the four

types of repair:

(1) Prior to cutting the tube, draw a line parallel to the tube run

across the section to be cut, using the marking pen and a ruler (see figure

4-80)

(2) Cut the tubing.

(3) If a tube end Is to be replaced, make sure the line Is placed in

the same location on the new tube as the tube section that has been

removed.

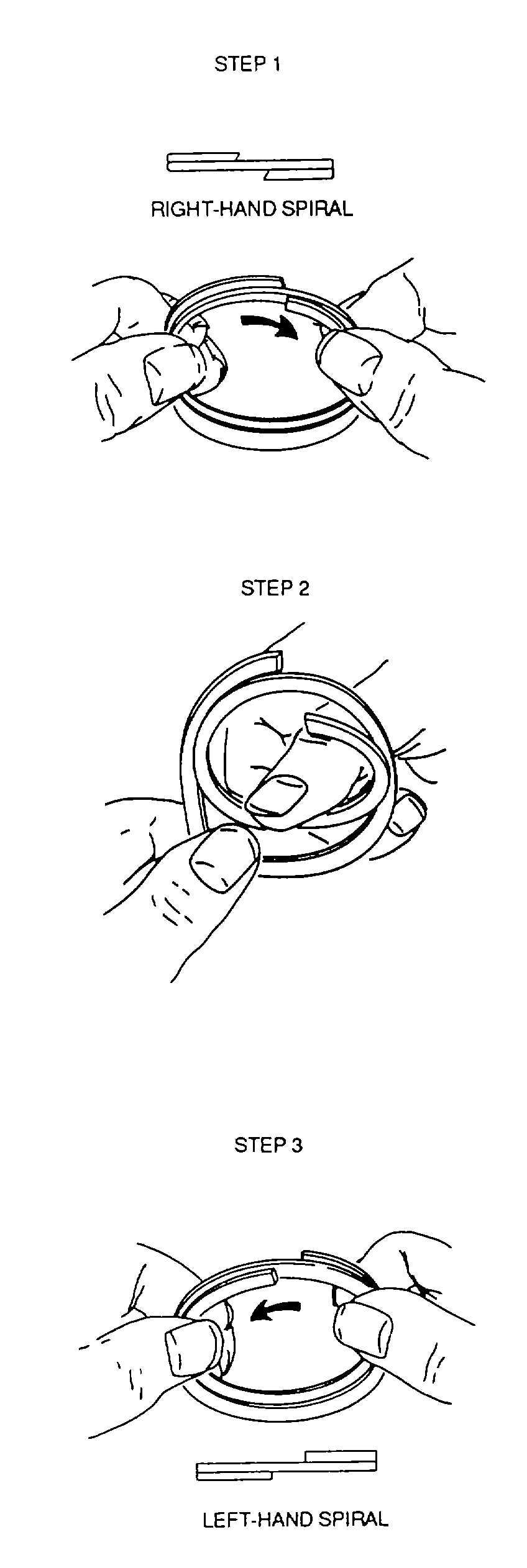

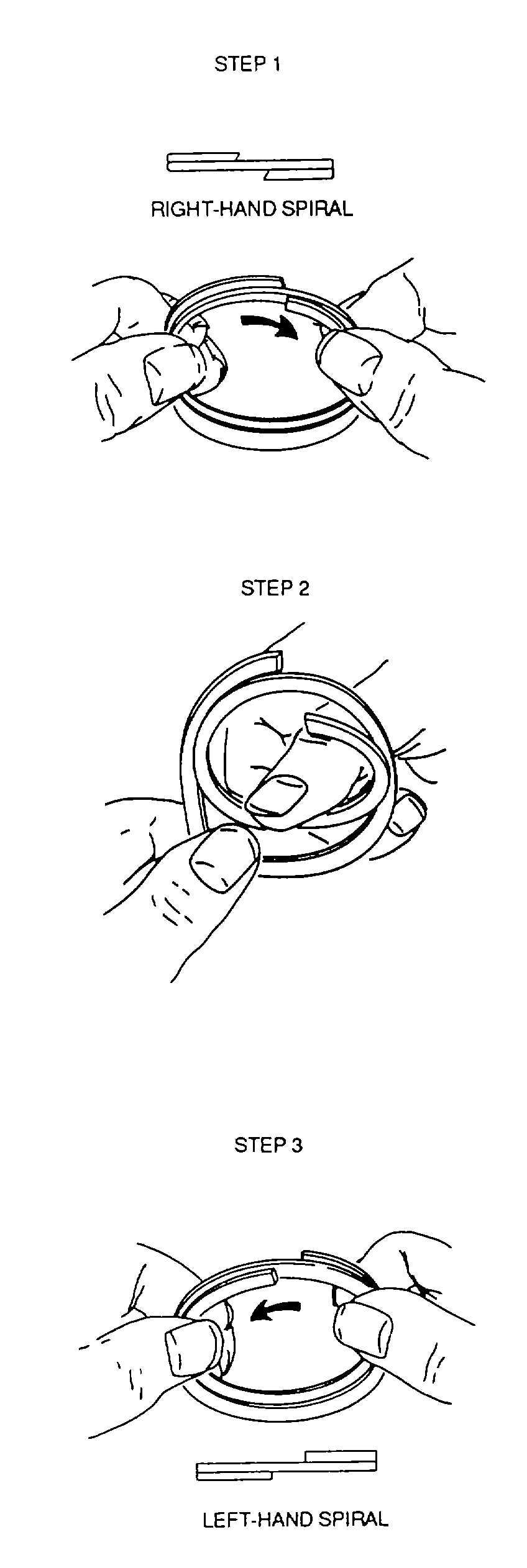

Figure 4-74. Reversing Spiral of

Teflon Backup Ring

4-87