TM 1-1500-204-23-2

NOTE

Tubing should be flared by the single flare method only in an emergency when a double flare tool is not

available.

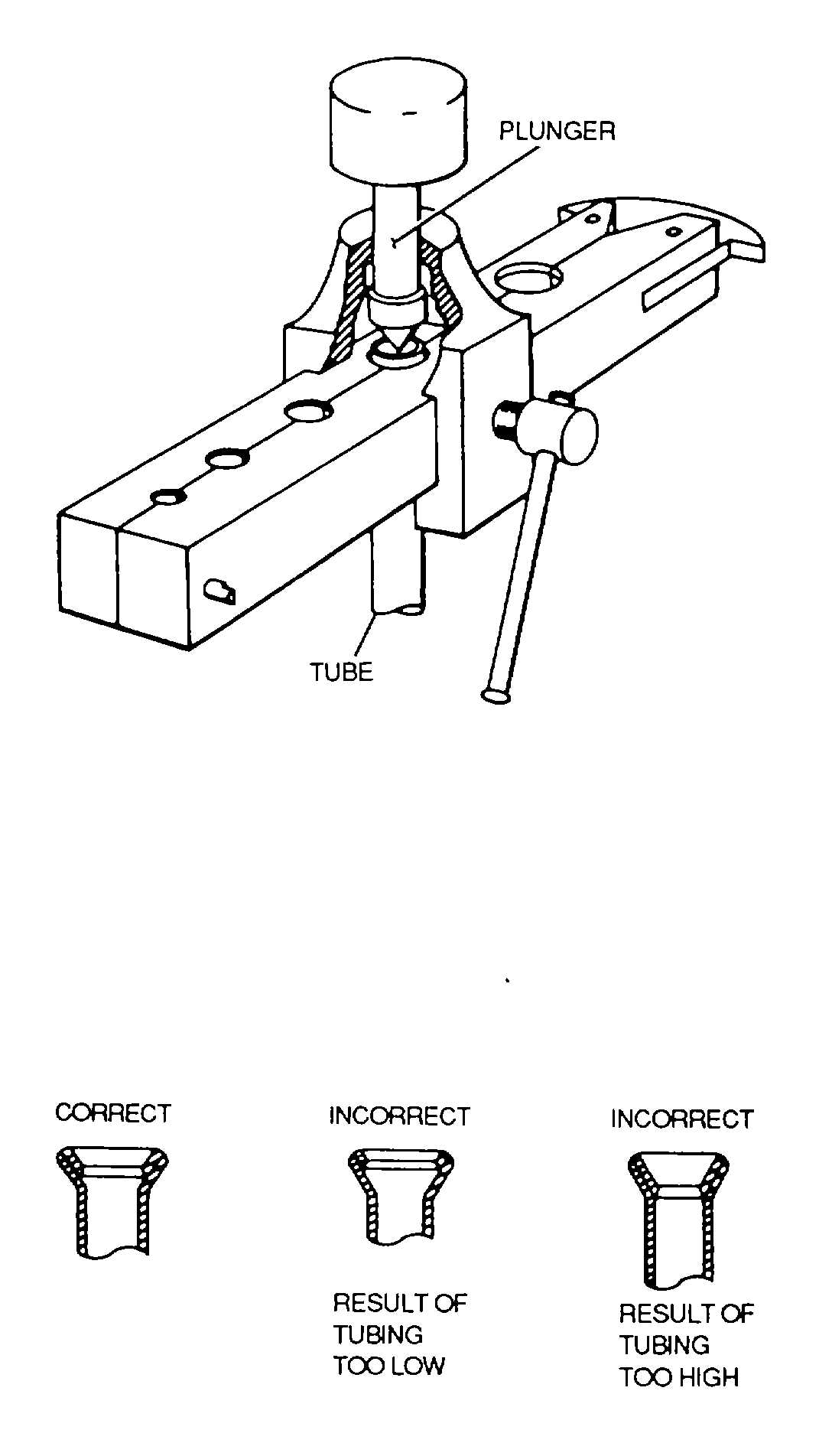

Figure 4-11. Tubing with Double Lap Flare

g.

Cleaning Tubing. After tubing is bent and ends are flared, it will thoroughly cleaned prior to installation in the

aircraft.

WARNING

Drycleaning solvent is flammable and solvent vapors are toxic. Use P-D-680, Type II Solvent in a well-

ventilated area. Keep away from open flames. Avoid prolonged solvent contact with skin.

WARNING

Compressed air shall not be used for cleaning purposes unless reduced to less than 30 psi and then only

with effective chip-guarding and personal protective equipment

CAUTION

To avoid oil base contamination, clean oxygen tubing and fittings in accordance with paragraph 4-2g (2).

NOTE

Store solvent in nonflammable storage cabinet when not in use.

(1)

Cleaning process. Clean tubing with suitable solvent to remove dirt, grit, or other foreign matter.

Always check the applicable technical manual (TM) for any special procedures for cleaning and testing. If no particular

type of solvent is specified in the applicable TM, use drycleaning solvent conforming to Federal Specification P-D-680

Type II, for petroleum and synthetic-base fluid lines. The part will be soaked and washed thoroughly in the solvent. All

parts must be completely dry before being assembled or installed. Use compressed dry, filtered air to dry parts. Keep

solvent in a tightly sealed container. When using solvent indoors, be sure that the work area is well-ventilated.

(2)

Cleaning oxygen system tubing. All oil and grease will be removed from oxygen tubing and fittings

using one of the following methods.

4-9

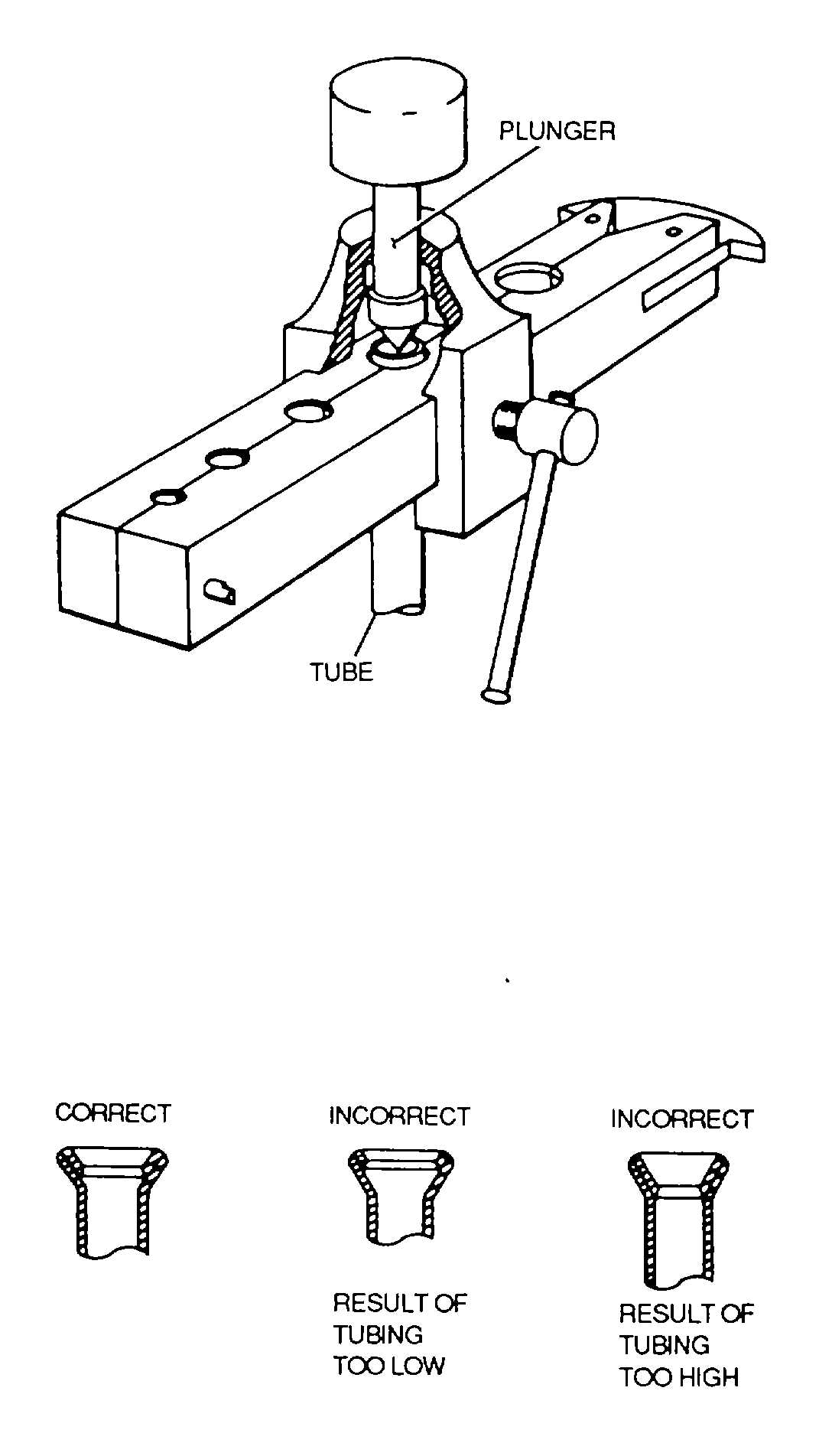

Figure 4-10. Flaring Tool