TM 1-1500-204-23-2

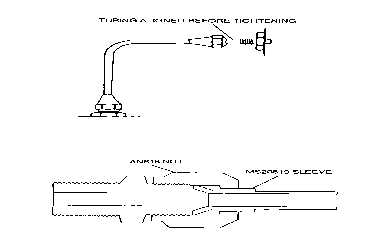

Figure 4-14. Tube and Fitting Alignment

Figure 4-15. Tubing Fittings

(b) Identification of tubing fittings. AN fit-

tings are easily Identified by their distinguishing colors;

blue for aluminum alloy and black for steel. Aluminum-

bronze fittings are cadmium plated, and are not other-

wise colored. Only steel fittings are used with steel

tubing 3/8-inch outside diameter and smaller. Intermix-

ing of tubing and fittings, other than above is permis-

sible.

(c) Thread compounds. Thread compounds

should not be used on flared tubing fitting threads. Use

of thread compounds should be limited to tapered male

pipe threads. In rare instances, it is possible to obtain a

flared tubing fitting manufactured to maximum tolerance

which, when coupled to a tubing nut manufactured to

minimum tolerance, will be difficult to tighten. If this

occurs, organizational, and direct and general support

maintenance activities are authorized to apply tape,

MIL-T-27730, to the first three threads toreduce friction.

Tape should not be allowed on the fitting cone as this

will prevent metal-to-metal contact.

NOTE

Depot level activities, including commercial

contractors, affecting overhaul, repair, or

modification of service aircraft are prohibited

from using antiseize compounds on flared

tubing threads. These activities will replace

fittings that are manufactured to maximum or

minimum thread tolerances.

(d) Replace cracked fitting sleeves. Crack-

ed fitting sleeves Installed on fuel, hydraulic, water, and

pneumatic tubing subjected to pressures up to and

including 3000 psi are not considered unsafe and do not

need to be replaced unless a leak occurs. If a leak

occurs, they must be replaced. An exception to this is

when a line is disconnected for any other reason, all

cracked fitting sleeves shall be replaced with service-

able fitting sleeves. These Instructions also apply to

cracked fitting sleeves on return, vent, and drain lines.

The above statements are not to be interpreted to mean

that a cracked fitting sleeve or sleeves cannot be

replaced at the discretion of responsible quality control

personnel. Minor surface corrosion on sleeves and fit-

tings, while not desirable, is acceptable. Whether or not

corroded sleeves and fittings will be replaced is also at

the discretion of responsible quality control personnel.

(2) Installation and replacement of tubing as-

semblies. Before a tubing assembly is Installed in an

aircraft, it shall be carefully inspected. Dents and

scratches shall be removed, proper nuts and sleeves

installed, and a proper fit obtained where tubing is

flared. Tubing assembly shall be clean and free from all

foreign matter. Sleeve and nuts shall be screwed to

mating fitting by hand and nuts tightened with proper

wrench. Tubing shall not be pulled into place with the

nut, but shall be properly aligned prior to tightening. If

tubing assemble is long; edges of cutout shall be taped

before tubing is Installed. The fitting wrench or open end

wrench shall be used when tightening. Pliers shall never

be used to tighten fittings Adjustable open end

wrenches may be used only when proper tools are not

available. Overtightening nuts may severely damage or

completely cut off tubing flares or may result in damage

to sleeve or nut of fitting. If nut and sleeve are removed

from a section of tubing, and flares are found to retain

less than 50 percent of their original wall thickness, tube

shall be replaced. Undertightening nuts may also be

serious, as this may allow tubing to blow out or leak at

fitting because of insufficient grip on flare by sleeve. Use

of torque wrenches will prevent undertightening. A nut

shall never be tightened to a torque when pressure is

on system, as this will tend to cut flare without adding

4-12