TM 1-1500-204-23-2

any appreciable torque to fitting Maximum wrench tor-

ques, in inch-pounds, for fitting nuts on various sizes

and types of tubing are shown In table 4-2.

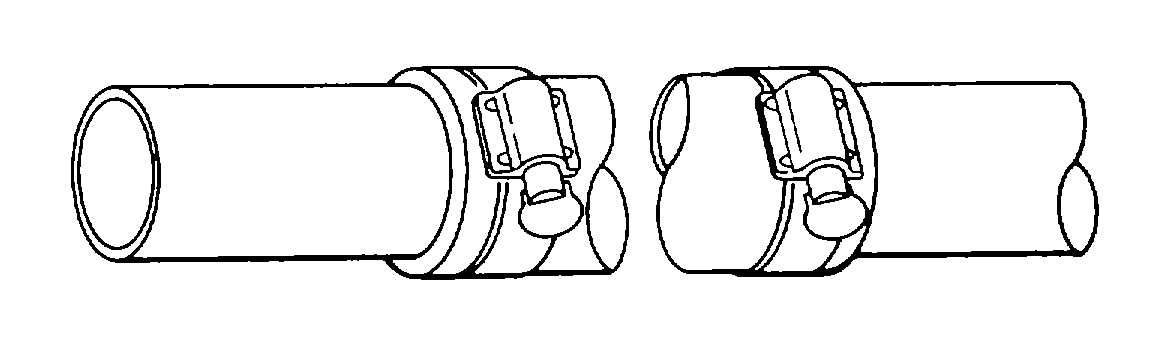

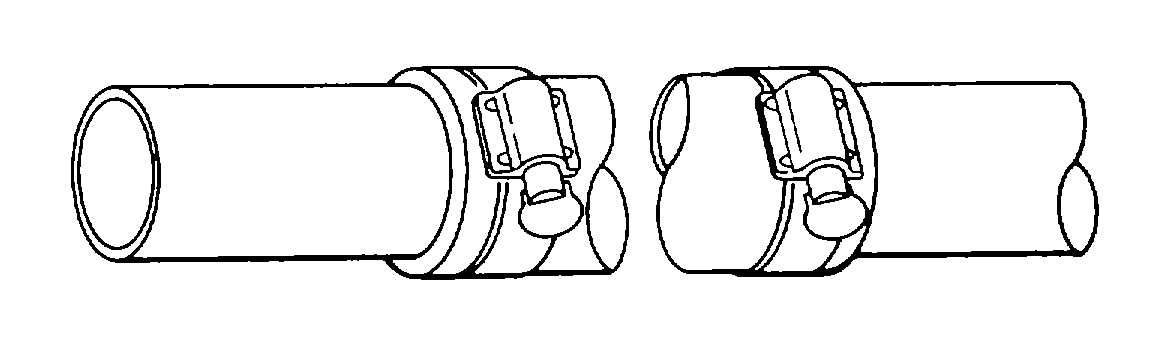

j. Installation of Beaded Tubing. Beaded tubing Is

used In low-pressure applications using rubber hose

and hose clamps (see figure 4-16).

(1) Proper sealing of hose connections. To

prevent breakage of hose clamps and damage to hose,

Instructions on tightening hose clamps shall be followed

carefully. When available, use any approved torque

wrench to torque hose clamps as per (2) or (3) below,

Figure 4-16. Installed Low-Pressure Hose

depending on the hose type. In the absence of a hose

clamp torque wrench, the fingertight-plus-turns method

shown in table 4-3 should be used. Due to the variance

in hose clamp design and hose structure, values given

in table 4-3 are approximate and care should be exer-

cised when tightening clamps by this method.

NOTE

Aircraft hose constructed with synthetic com-

pound has tendency to cold flow. Therefore,

when new hose is installed, clamps should,

after a period of time, be retightened in order

to maintain original torque value. This Is

caused by synthetic rubber flowing from

under clamping area and not from loosening

of clamps

Table 4-2. Hydraulic Tubing B-Nut (AN818) Torque Values

Torque on tube nut

Tube outside

Aluminum alloy

Steel tubing

diameter

tubing

1/4 Inch

40-65 Inch-Pounds

135-150 Inch-Pounds

5/16 Inch

60-80 Inch-Pounds

180-200 Inch-Pounds

3/8 Inch

75-125 Inch-Pounds

270-300 Inch-Pounds

1/2 Inch

150-250 Inch-Pounds

450-500 Inch-Pounds

5/8 Inch

200-350 Inch-Pounds

650-700 Inch-Pounds

3/4 Inch

300-500 Inch-Pounds

900-1,000 Inch-Pounds

1 Inch

500-700 Inch-Pounds

1,200-1,400 Inch-Pounds

4-13