TM 1-1500-204-23-2

Table 4-3. Hose Clamp Tightening, Fingertight-Plus Turns Method, Beaded Tubing

Clamps, radial

Initial Installation

Clamp, worm screw-type

and other type

only

(10 threads per inch)

(28 threads per Inch)

Self-Sealing Hose

Fingertight Plus 2

Fingertight Plus 2 1/2

Complete Turns

Complete Turns

Approximately 25 to 30

Inch-Pounds

All Other Aircraft Hose

Fingertight Plus 1 1/2

Fingertight Plus 2

Approximately 25 to 30

Complete Turns

Complete Turns

Inch-Pounds

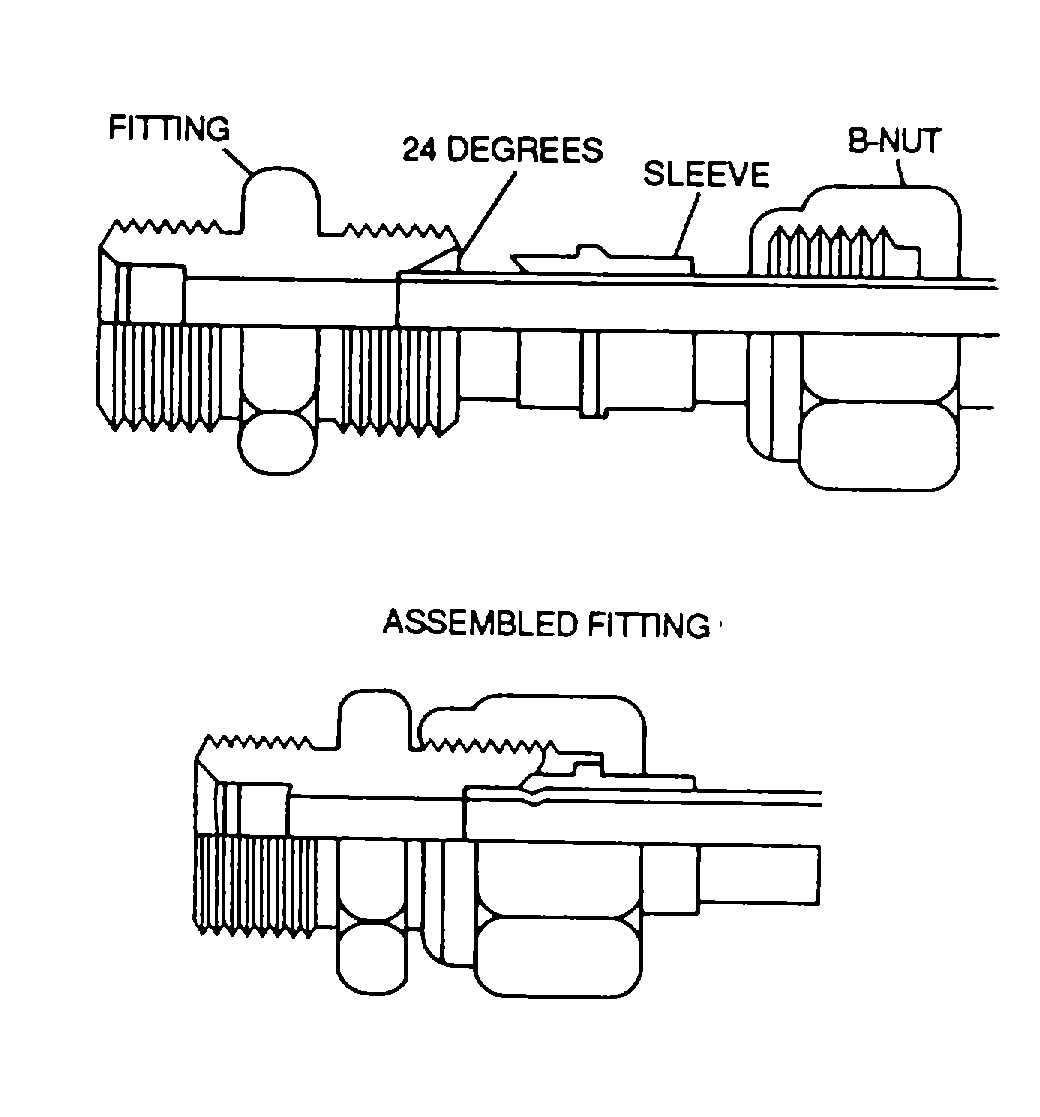

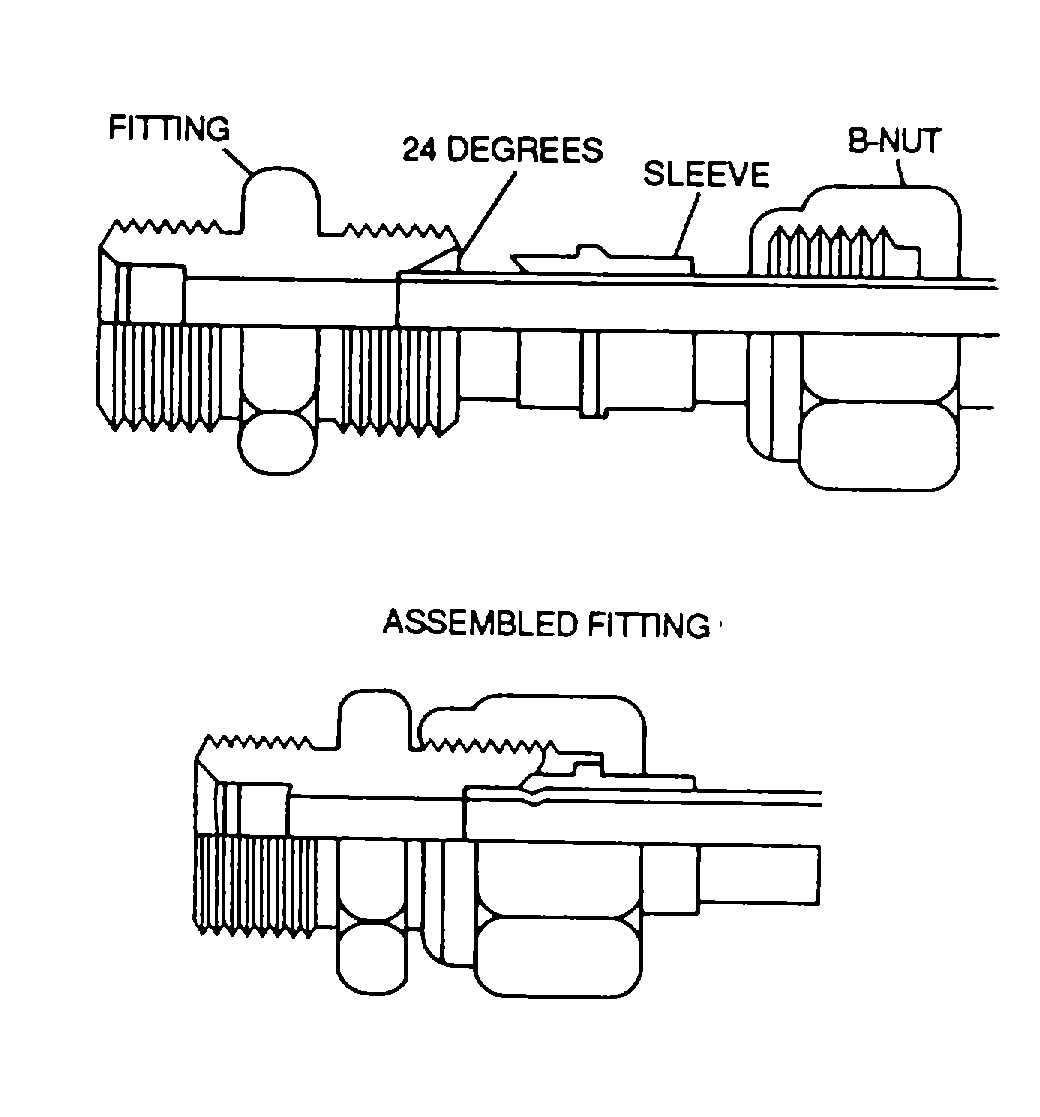

Figure 4-17. MS Fitting and Components

(2) Clamps on self-sealing hose. Hose

clamps installed on self-sealing hose shall be tightened

to a torque of 25 inch-pounds minimum to 30 inch-

pounds maximum for original installation, and main-

tained at this torque value. When sealing is not

effective at 30 inch-pounds, component parts of con-

nection shall be examined, and unserviceable parts

replaced Under no circumstances shall hose clamp be

tightened in excess of 30 inch-pounds in an attempt to

effect sealing This added torque will reduce safety

factor of hose clamps as well as destroy hose and

connection.

(3) Clamps on nonself-sealing hose. Hose

clamps installed on nonself-sealing hose shall be in-

stalled and maintained at a torque of 25 inch-pounds

minimum to 30 inch-pounds maximum. If satisfactory

sealing is not accomplished at a torque of 30 inch-

pounds, component parts of connection shall be ex-

amined and unserviceable parts replaced.

4-3. Fittings. Hydraulic fittings are used

throughout the hydraulic system to provide simple

connections between hydraulic components and

tubing. Standard MS (flareless) and AN (flared) fittings

are used in Army aircraft. Both types are made in many

different shapes and designs. They may be ordered in

either male or female design or in a combination design

(male on one end and female on the other). The

hydraulic repairer is concerned with installing both the

AN and MS fittings in aircraft hydraulic systems. Nor-

mally, the fittings to be used in an aircraft hydraulic

system are selected according to the design of the

system. The hydraulic repairer repairs fitting failures by

duplicating the original installation.

4-14