TM 1-1500-204-23-2

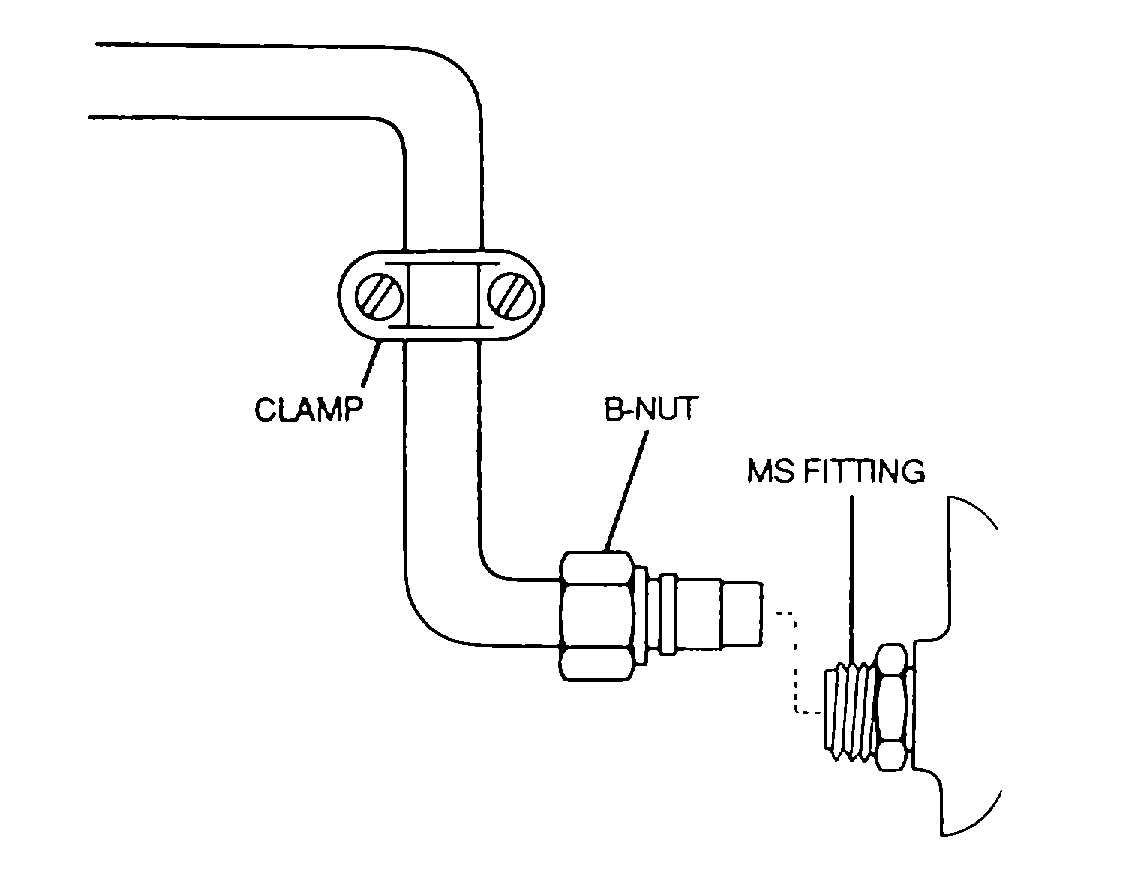

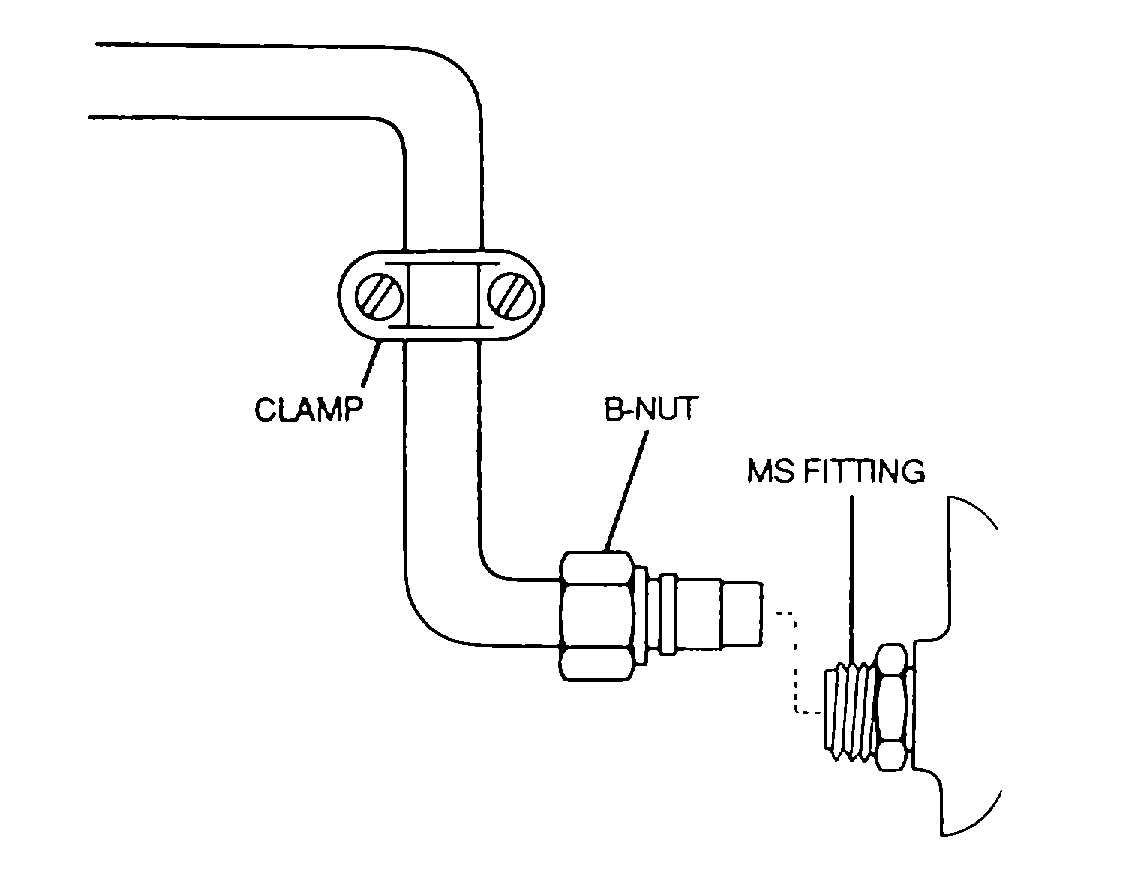

(c) Tube-to-tube connections. To make a

tube-to-tube connection, the tube B-nut is tightened until

a definite resistance is felt and is then turned one-sixth

of a turn farther. The upper wrench is held stationary

while the lower wrench is moved upward until the B-nut

is tightened a sufficient amount (see figure 4-22). On

this tube connection, like most others, a 1/8-inch colored

stripe may be painted across the completed assembly

so that loosening can be readily detected (see figure

4-23).

(4) Bulkhead fitting installation. These fittings

are used for connecting tubing to components of the

system, and for connecting sections of tubing where the

line passes through a bulkhead and the fitting is secured

to the bulkhead, as shown in figure 4-24. Refer to table

4-4 for the correct fitting size.

(a) Hand presetting of MS21922 sleeve.

The MS21922 sleeve can be preset using the following

procedures:

1 Bottom the tube end firmly In the seat of

the preset tool or fitting.

2 TightentheMS21921 nut1 1/6 turns past

the point of ring grip on all sizes and materials for all

types of fittings or tubes.

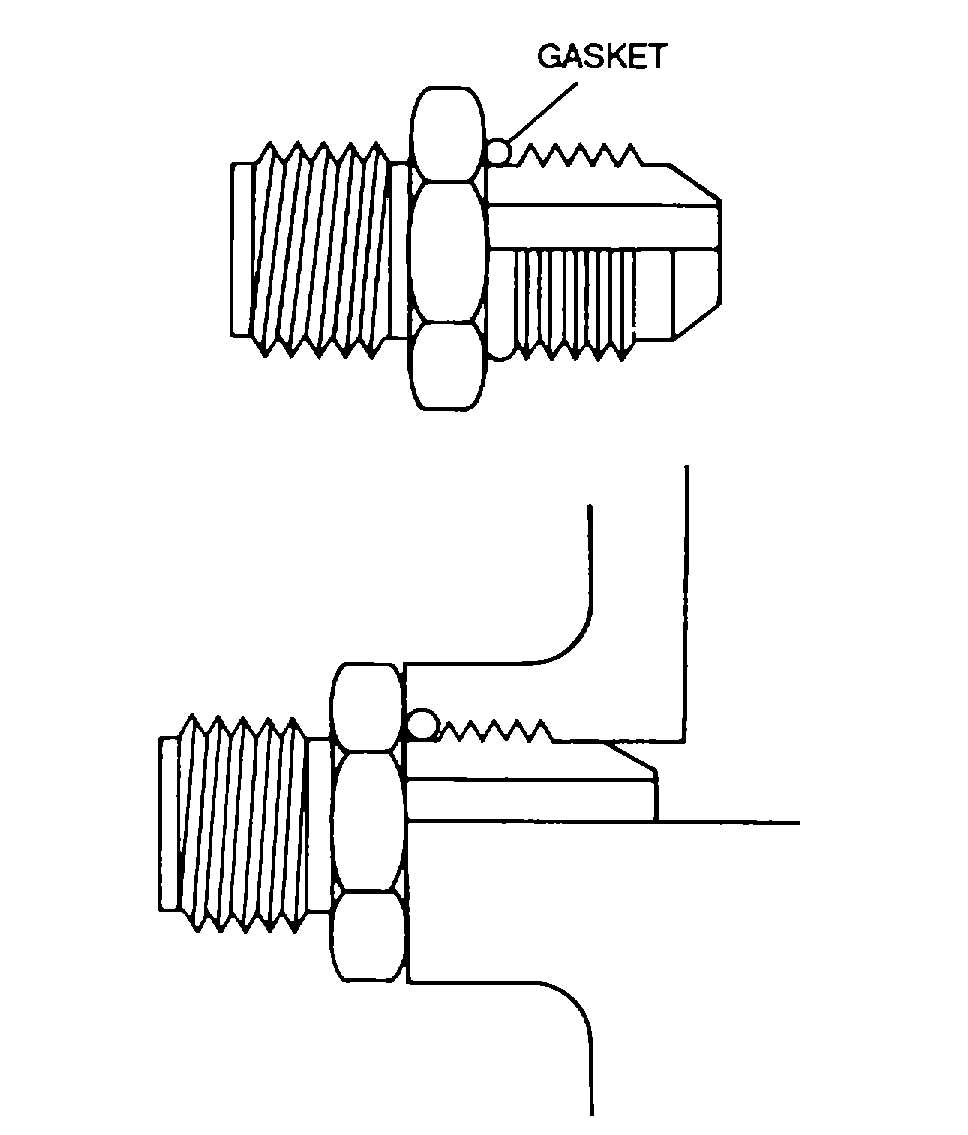

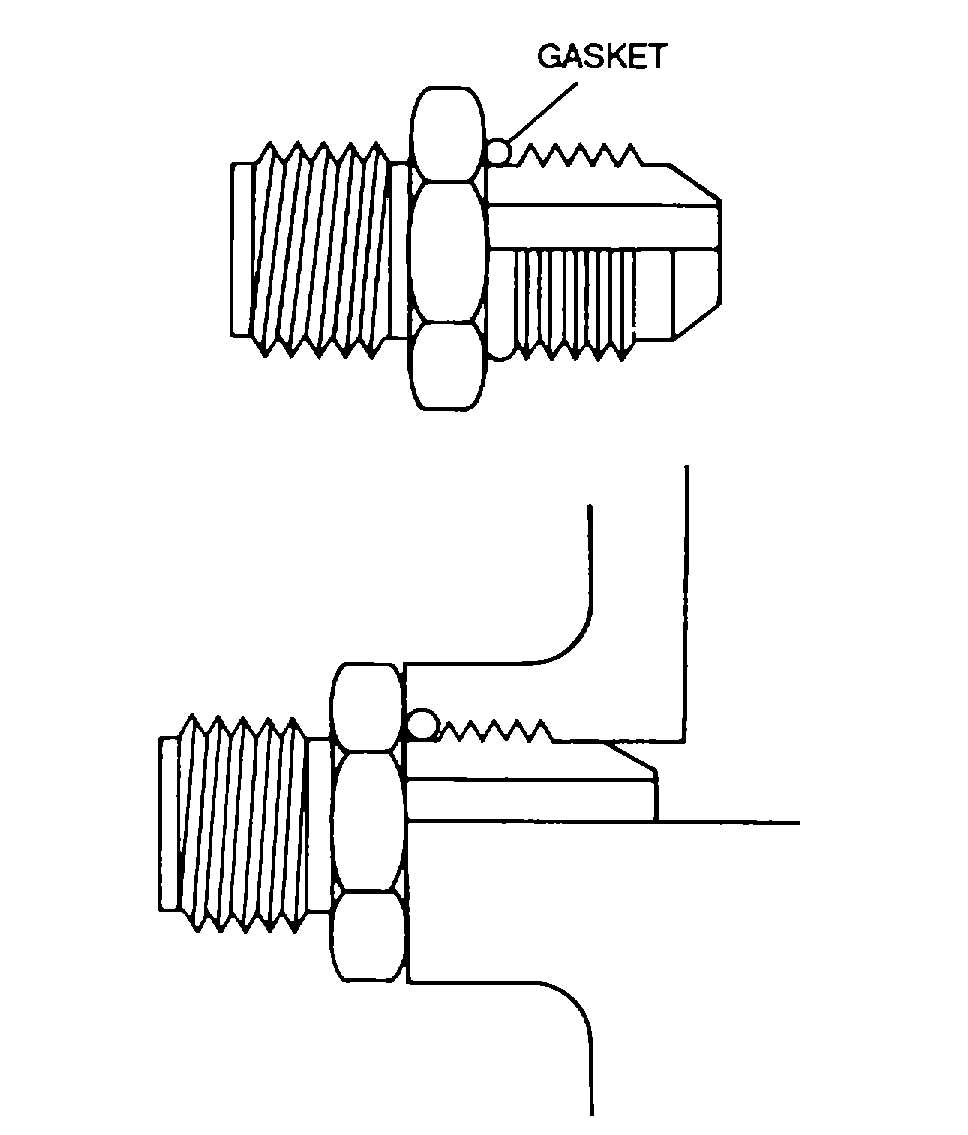

Figure 4-19. MS Fitting Gasket Installation

(b) Resetting (Installation). Tighten the

MS21921 nut in accordance with table 4-5.

(c) Boss installation of MS33514 fitting end,

style E. This fitting can be Installed as follows

1 Lubricate the packing in appropriate lie-

id (refer to table 4-6).

2 Install packing on the fitting as shown In

detail A, figure 4-25

3 Screw the fitting assembly into the boss

using installation torque In accordance with table 4-7

(d) Installation of AN 924 jamnut. Torque

values can be found In table 4-8.

b. Oxygen System Tapered Pipe Thread.

Tapered pipe thread fittings are a versatile and efficient

method of connecting tubing to components.

(1) Tubing fittings tapered pipe threads. Pipe

threads should conform to MIL-P-710-5. Straight thread

and tapered pipe thread are shown In figure 4-26.

NOTE

When installing pipe thread fittings, fittings

should be tightened but not enough to

damage threads or crack the part In which

fitting is being Installed.

Figure 4-20. Tubing Alignment

4-17