TM 1-1500-204-23-6

h

Internal Wrenching Nuts. Use internal wrenching nuts, NAS443, where heat-treated, self-locking nuts are

specified to carry high strength bolt tension loads.

i.

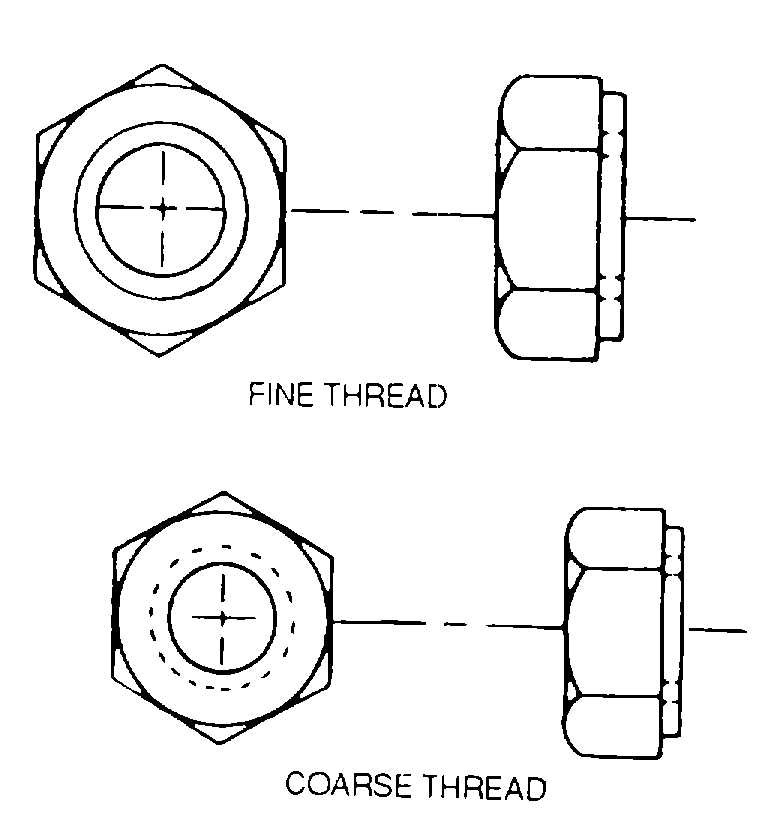

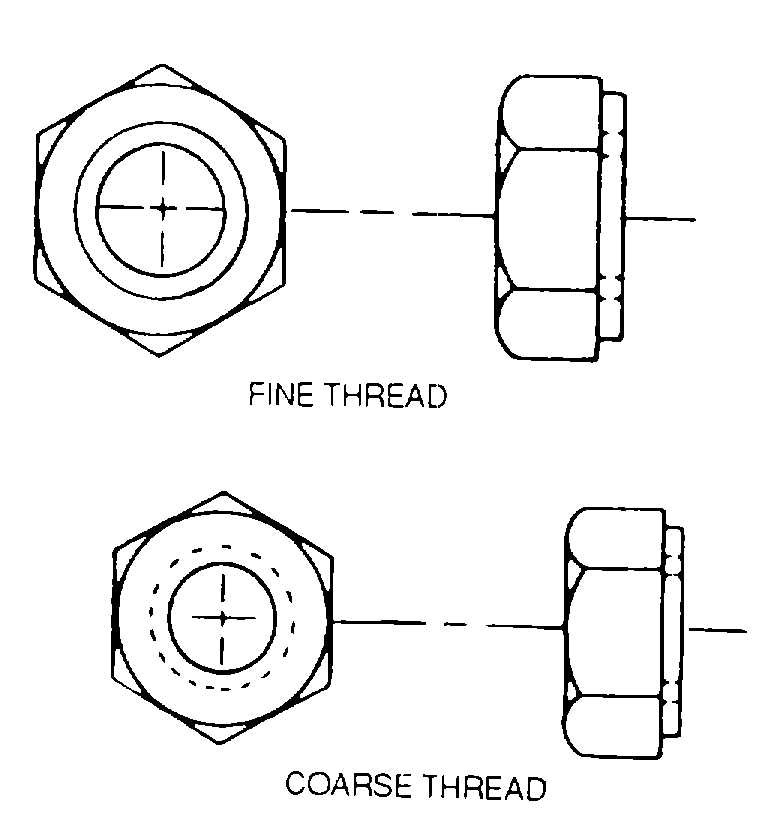

Identification of Nuts. Any nut may be identified provided the type can be determined and mating bolt or screw is

available Determine major diameter of bolt or screw with a micrometer Use a thread pitch gauge to match threads of bolt

The number marked on the gauge segment will indicate the threads per inch, the thread pitch, and the inside diameter of

the nut required.

NOTE

Proper gauge segment is ensured when no light is seen between the

pitch of the bolt threads and the pitch of the gauge segment

j

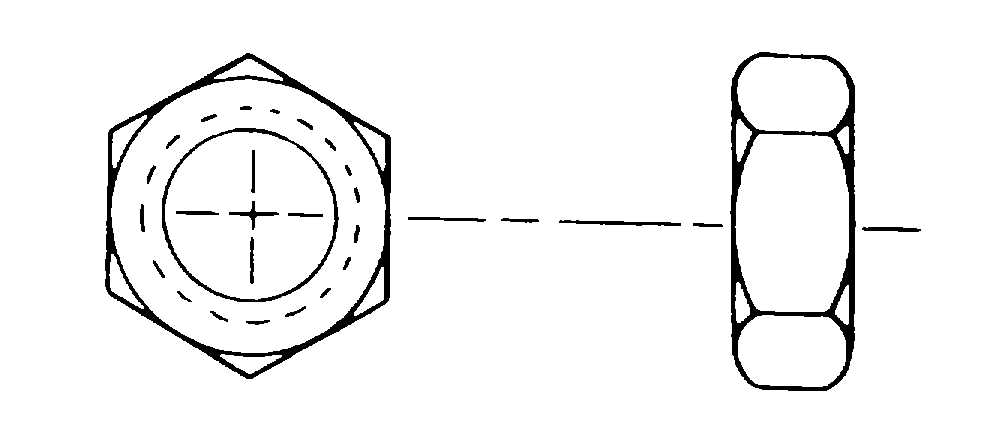

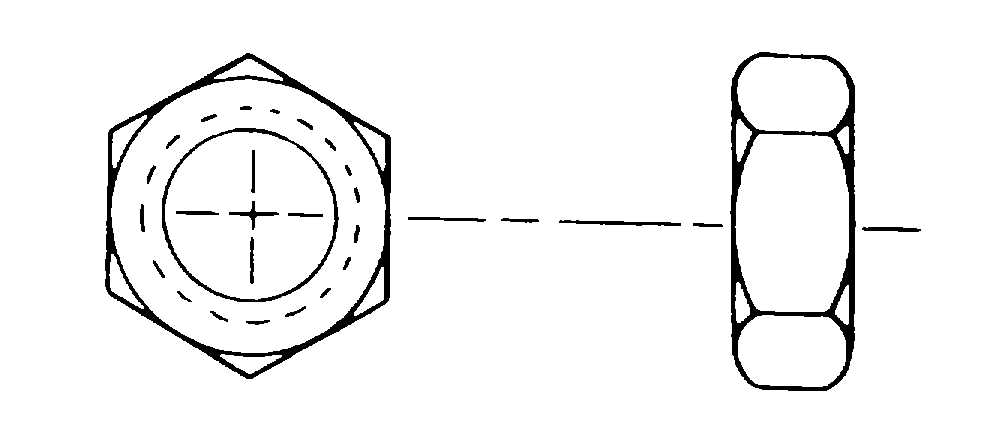

Airframe Plain Nuts. Use airframe plain nuts AN315, as shown in figure 2-28, in structural application. An

auxiliary locking device, such as a checknut, or a lockwasher, is required when this type nut is used.

2-4.

Washers. Washers used in aircraft structures are plain lockwashers, and special washers

a. Plain Washers. The AN960 plain washer, as shown in figure 2-29, is used under AN hexagon nuts to provide a

smooth bearing surface It acts as a shim in obtaining the correct relationship between the threads of the bolt and the nut

It will adjust the position of castellated nuts with respect to drilled cotter pin holes in bolts.

(1)

Uses The general rule is to use one washer under each nut. However, if one washer falls to cover the

underthread grip or falls to place the nut in the proper position for cotter pins, then one more washer may be added if

more than two washers are needed, the bolt length should be changed. Other use criteria are as follows.

Use a cadmium-plated steel washer under the nut with the washer bearing directly against the structure unless otherwise

specified.

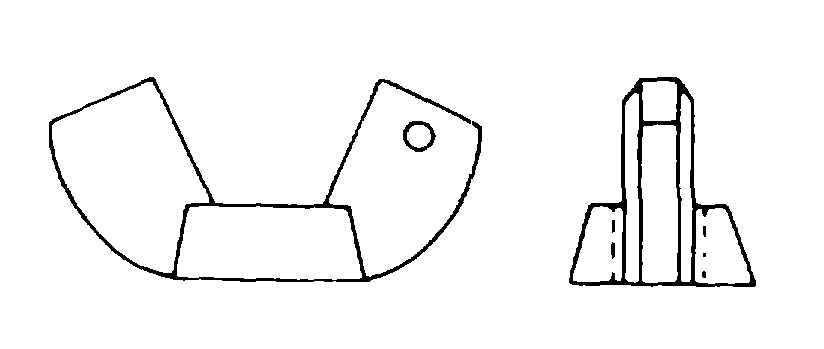

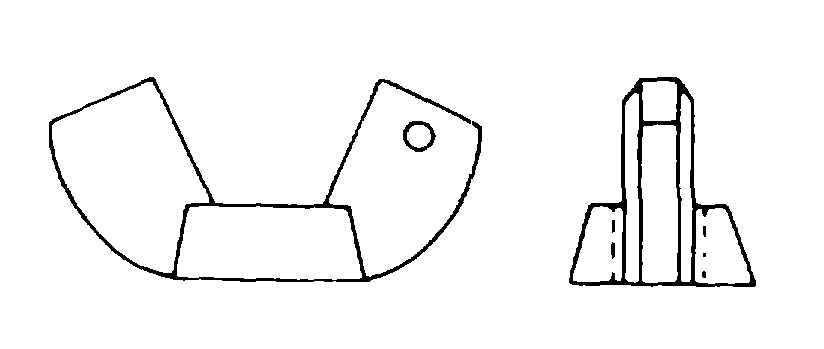

Figure 2-24. Plain Checknut

Figure 2-25. Light Hexagon Nuts

Figure 2-26. Wingnut

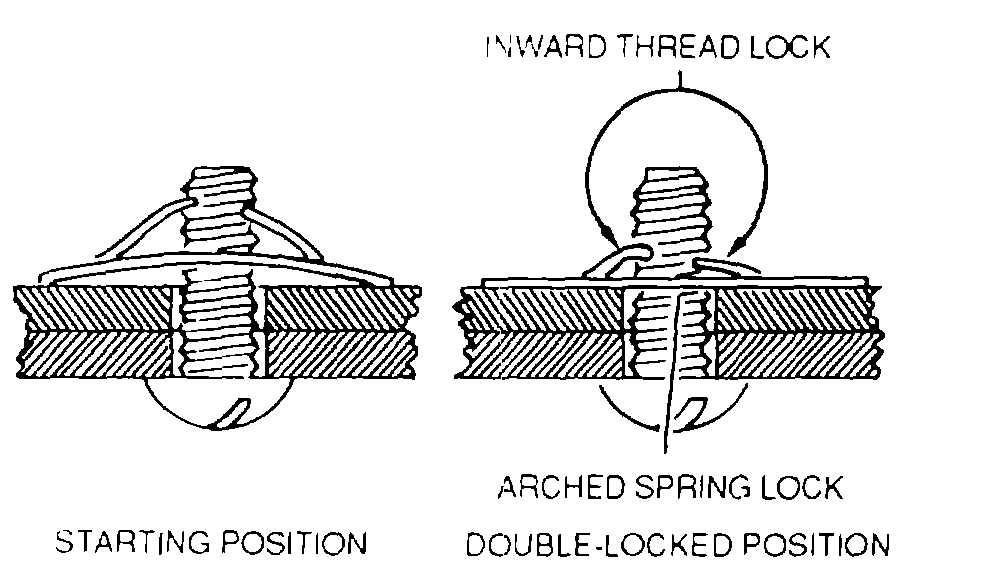

Figure 2-27. Sheet Spring Nut

2-34