TM 1-1500-204-23-6

(4)

Substitution.. AN310 castellated nuts (paragraph 2-3b) may be substituted for MS21042 and MS21044

nuts, provided the AN310 nuts are secured with cotter pins. AN320 castle shear nuts may be substituted for

MS21042, MS21083, and MS21245 nuts.

NOTE

These substitutions may be made when self-locking nuts are not

available

(5)

Temperature designations. High-temperature self-locking nuts are identified by the numeral 12 stamped

into the metal They will withstand temperatures as high as 1200

°F (649°C) Some high temperature self-locking nuts

are identified by a letter H stamped into the metal They will withstand temperatures as high as 550

°F (288°C).

Standard self-locking nuts have no special markings, but are used within the temperature range of 0 to 250

°F (-18 to

121°C.)

b. Castellated Nuts. There are three types of castellated nuts. They consist of airframe, shear, and engine castle

nuts

(1)

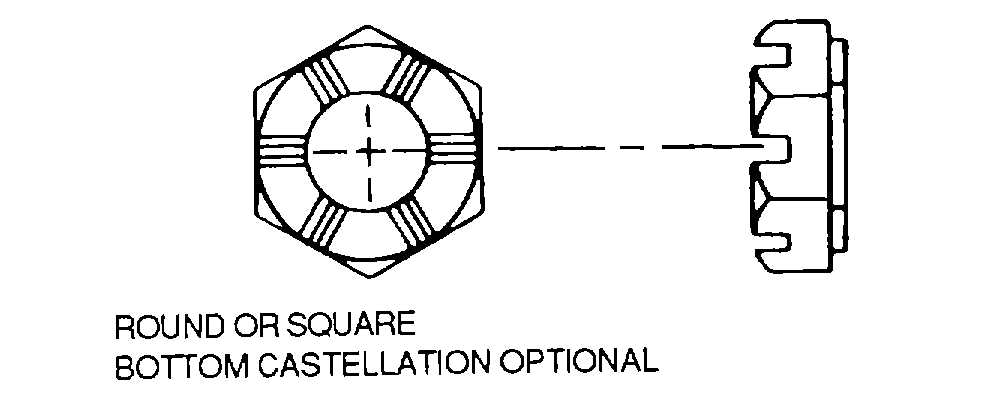

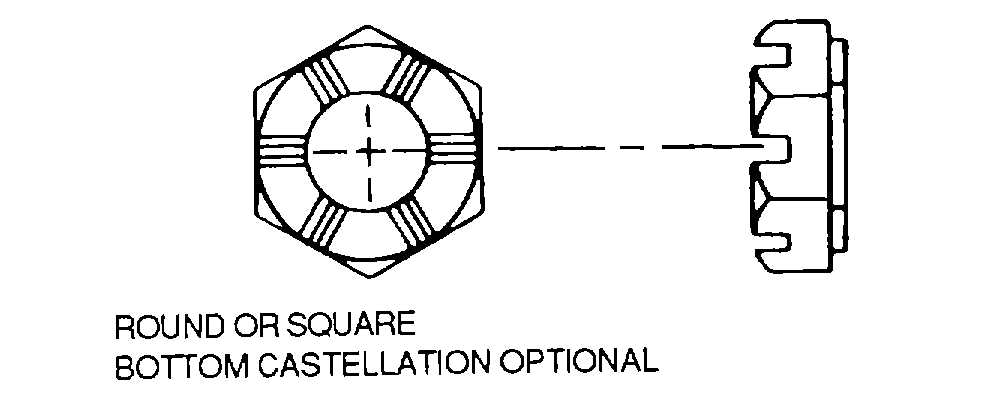

Airframe Use AN310 airframe castellated nuts, as shown in figure 2-22, in conjunction with drilled head

bolts or studs. Use a cotter pin or lockwire to secure this nut

(2)

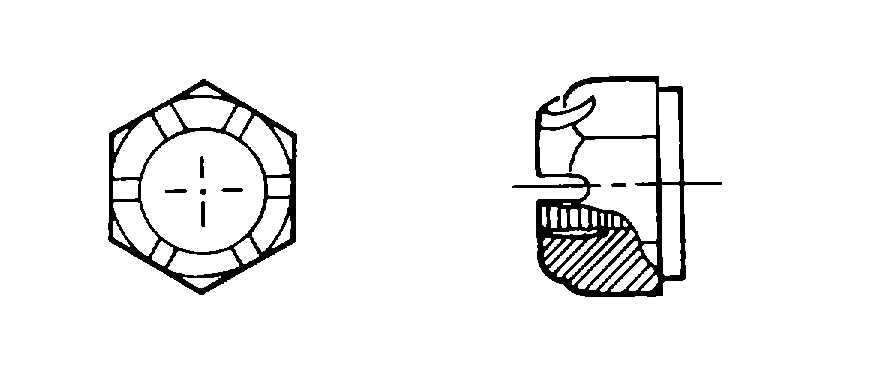

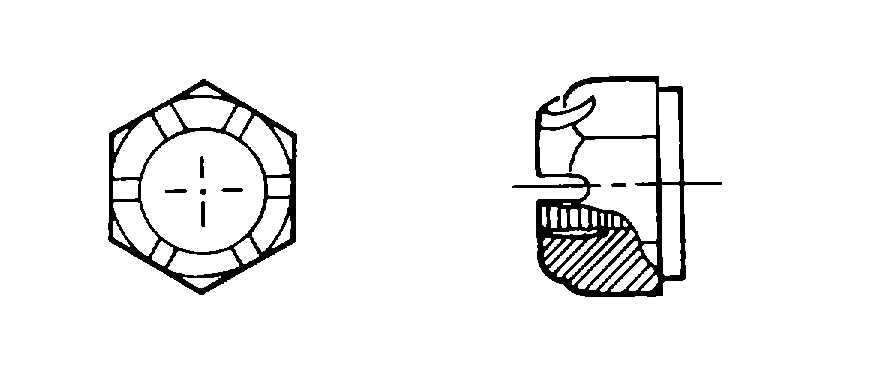

Shear Use AN320 airframe castellated shear nuts, as shown in figure 2-23, for those devices, such as

drilled clevis bolts and threaded taper pins, that are subjected to shear loads only.

(3)

Engine. Engine castle nuts, AN121551 through AN121575, are identified by E11 stamped into the metal

Do not substitute any other type nut.

c. Checknuts. Use AN316 aircraft plain check-nuts, as shown in figure 2-24, as a locking device for plain nuts,

setscrews, threaded rod ends, and other similar Items

d. Jamnuts. Use hexagon jamnut, NAS509, with a washer, NAS513, for locking rod-end terminals to hydraulic

piston rods Use lockwire as an additional locking device

e. Light Hexagon Nuts. Use MS35649, MS35650, and MS35690 light hexagon nuts, as shown in figure 2-25, in

miscellaneous nonstructural applications. An auxiliary locking device should be used with these nuts.

f.

Wingnuts. Use MS35425 and MS35426 wingnuts, as shown in figure 2-26, where desired tightness is ordinarily

obtained by the fingers, and where the assembly is removed frequently. When a plain wingnut requires securing with

lockwire, a 0 070 inch ( 0.010 inch) diameter hole must be drilled in the center of one lobe The WC02 self-locking

wingnut does not require lockwire.

g. Sheet Spring Nuts. Sheet spring nuts, NAS444, NAS445, NAS446, and NAS395, as shown in figure 2-27, are

commonly called speed nuts. Use with standard and sheet metal self-tapping screws in various nonstructural locations

Speed nuts in supporting line clamps, conduit clamps, electrical equipment, access doors, and other similar items.

Speed nuts are made from spring steel and are arched prior to tightening The arched spring lock prevents the screw from

working loose They are easily inserted, and finger pressure keeps them from turning. The use of the wrenches is

unnecessary Use speed nuts only where originally used in fabrication of the aircraft.

Figure 2-22. Airframe Castle Nut

Figure 2-23. Shear Castle Nut

2-33