TM 1-1500-204-23-6

(1)

Principle of operation. Spring pins are manufactured with the diameter greater than the holes in which

they are to be used. The spring pin is compressed as it is driven into the hole, and it exerts continuous spring pressure

against the sides of the hole to prevent loosening by vibration. Spring pins require no other means of securing, and can

be used inside one another to increase strength.

NOTE

Exercise care when using these pins, as performance depends entirely

on the fit, and the permanence of the fit under vibration or repeated load

conditions (especially in soft materials, such as aluminum alloys and

magnesium) has not been established. They shall not be used in an

aircraft component or system where the loss or failure of the pin might

endanger the safety of flight of the aircraft.

(2)

Application. The spring pin is designed for use in double shear applications. The proper bearing factors

for double shear application shall be established for the material in which the spring is being used; that is, whether the

material is heat-treated steel, corrosion resistant steel, aluminum alloy, or magnesium The following precautions will be

observed when determining the appropriate use of spring pins:

•

Spring pins should not be mixed with other structural fasteners in the same joint. These pins, for primary

structural applications, should be used only where there will be no rotation or relative movement under

load of the parts to be joined.

•

When temperatures are above 500

°F (338°C), steel spring pins shall not be used. Corrosion-resistant

steel spring pins shall not be used when temperatures are in excess of 700

°F (371°C).

•

The spring pin shall not be used as a substitute for a cotter pin nor in applications subjected to shock

loading unless the installation has been tested for fatigue life and has proven satisfactory.

•

When the spring pin is used in a clevis joint, it is recommended that the pin be held by the outer members

of the unit for maximum efficiency and reduced maintenance.

(3)

Reuse. Spring pins may be reused if a careful inspection reveals no deformation of the pin or hole. Be

careful to observe that the hole has not enlarged or deformed preventing proper functioning of the spring pin. Where

hole misalignment results in the pin gap closing, or necessitates excess inserting force, the spring pin shall not be used.

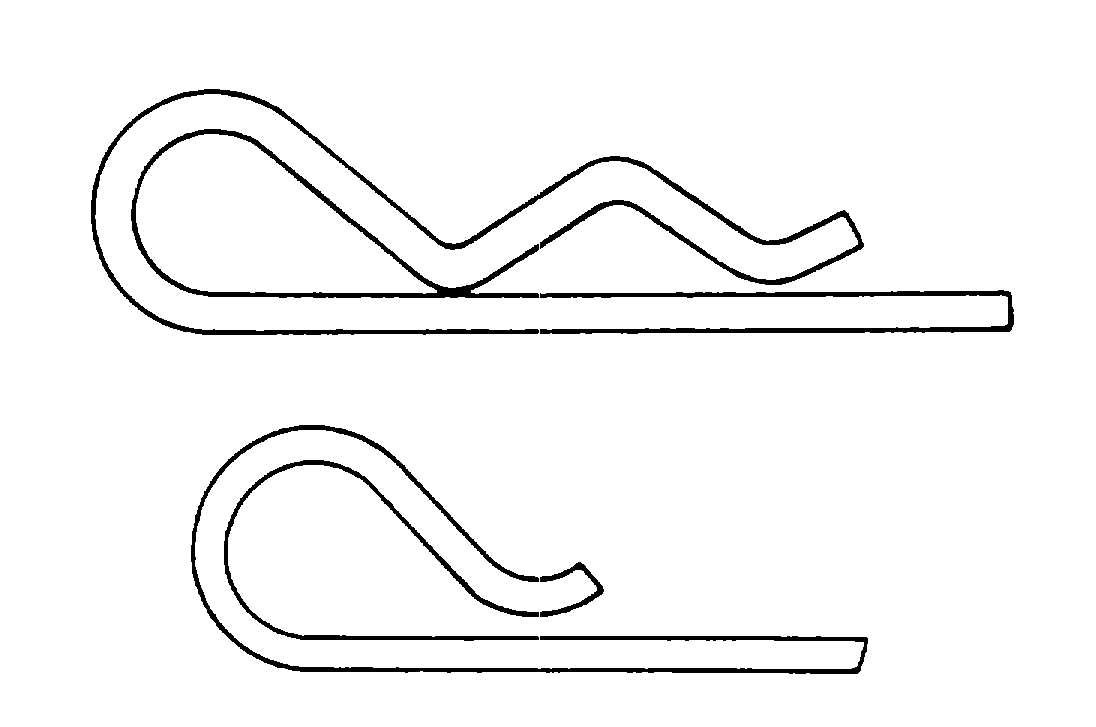

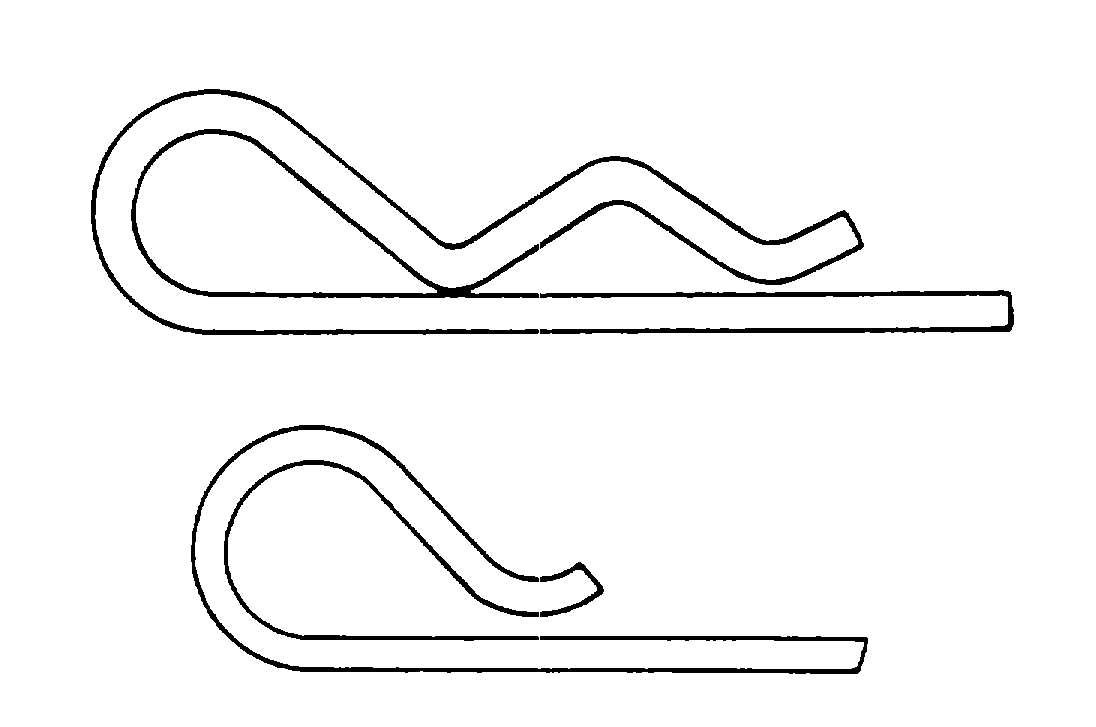

e. Lockpins. There are two types of lockpins, as shown in figure 2-51. Both are installed by placing straight section

of pin in hole of item to be locked and continuing to insert the straight portion of the pin until the curves or spring portion

of the pin latches over the item to be safetied Lockpins are normally used to secure items such as fuel and oil caps.

Figure 2-51. Lockpins

f.

Hinge Pins. Use hinge pins, MS20253, to join hinges, MS20257, in such locations as cowling access doors.

These pins are peened on ends as a method of securing. Treat ends with zinc chromate primer, Federal Specification

TT-P-1757, after peening to prevent corrosion.

g. Cotter Pins. Cotter pins are used to secure bolts, nuts, pins, screws, and in any other applications where such

locking is required. Figure 2-52 illustrates cotter pin designs.

2-44