TM 1-1500-204-23-6

g. Substitution and Interchangeability. Substitution of rivets generally depends on material, size, and head style.

Material considerations must be followed in substituting one rivet material for another. Other factors which must be

considered in substitution are described in the following paragraphs

(1)

Protruding-head rivets. All protruding-head rivets can be replaced by universal-head MS20470 rivets

(2)

Countersunk-head rivets. Countersunk-head rivets should be replaced by rivets of the same type and

degree of countersink. When the required countersunk-head rivets are not available, a raised head rivet may be driven

from the opposite side and upset into the countersink. Use care in this operation to keep the flat surface of the tools

parallel to the work Rivet length should be such that both the hole and the countersink are completely filled. When this is

impractical, the drilled out rivet head may be used as a washer and a universal-head rivet inserted and driven in the

normal manner in such cases, extreme care must be exercised to drill the hole in the center of the countersunk rivet

head.

NOTE

The procedures outlined above should be confined to interior work, and

should not be used in exterior applications on flush-riveted skin surfaces.

(3)

Solid shank rivets. Cadmium-or zinc-plated steel standard bolts, or NAS structural screws, may

be used to replace standard solid shank rivets only when the proper rivets or riveting equipment are not available in such

cases, steel bolts or screws of the same size as the replaced rivets are adequate for replacing any type rivet Observe the

following precautions:

•

Obtain a close fit in such installation.

•

Rapid deterioration is experienced by zinc-plated bolts subjected to high temperatures; therefore, zinc-

plated bolts are not to be used in place of corrosion-resistant steel rivets where temperatures over 700

°F

(371°C) are to be encountered.

•

Lowering of corrosion resistance is experienced by cadmium-plated bolts subjected to high temperature,

therefore, cadmium-plated bolts are not to be used in place of corrosion-resistant steel rivets where

temperatures over 400°F (204°C) are to be encountered.

•

Countersunk-head screws may be used to join thin dimpled sheets with threads in bearing, since the load

carried from sheet to sheet through the dimples Imposes a load on the screw in tension rather than in

shear.

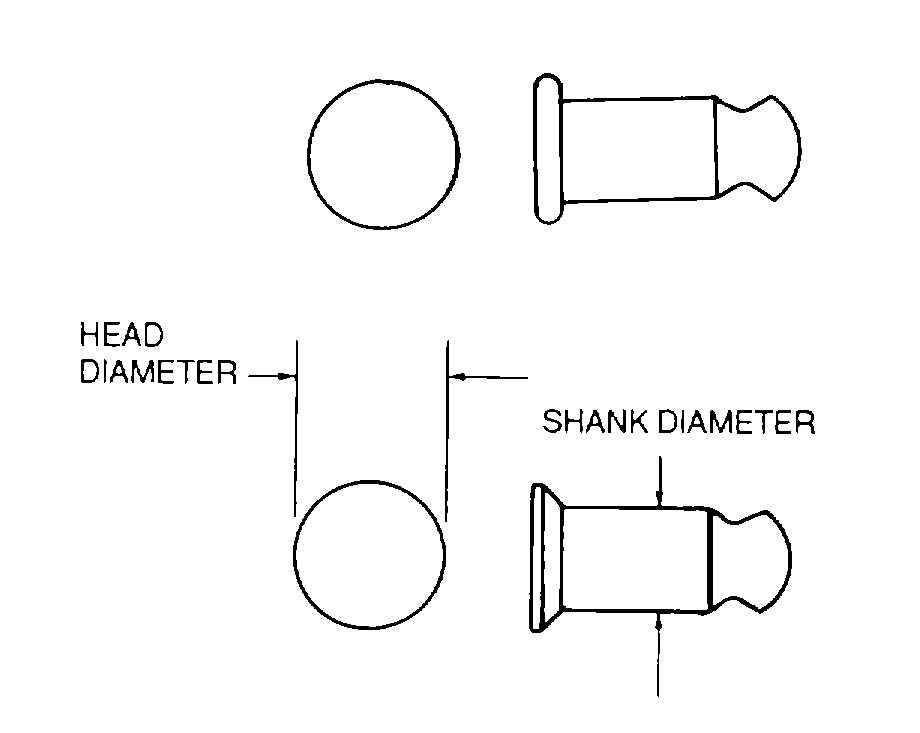

h. Hi-Shear Rivets. Hi-shear (pin) rivets, as shown in figure 2-54, are essentially threadless bolts which are inserted

like rivets Each rivet consists of two parts a stud and a collar. The stud is made of 4130 alloy steel, or equivalent, heat-

treated to 125,000 to 150,000 psi, and cadmium-plated The collar is anodized 2117-T4 aluminum alloy. The installed

rivet can be readily identified by the presence of the attached collar rather than the ordinary formed head of the standard

rivets Use Hi-shear rivets in shear applications only As the shear strength of the steel is considerably greater than either

the shear bearing strength of aluminum alloys, these special rivets are used to advantage only in the thicker sheet

gauges Never use Hi-shear rivets where the grip length is less than the shank diameter (3/16-inch for smallest available

rivet). Use the 100-degree countersunk type where flush surfaces are desired Hi-shear rivets may be replaced with close

tolerance bolts of the same material, strength and diameter, where absolutely necessary. Use flush-headed bolts for

flush-headed rivets and protruding head bolts for protruding head rivets. The bolt thread must not extend into the

material.

Figure 2-54. Hi-Shear Rivets

2-47