TM 1-1500-204-23-7

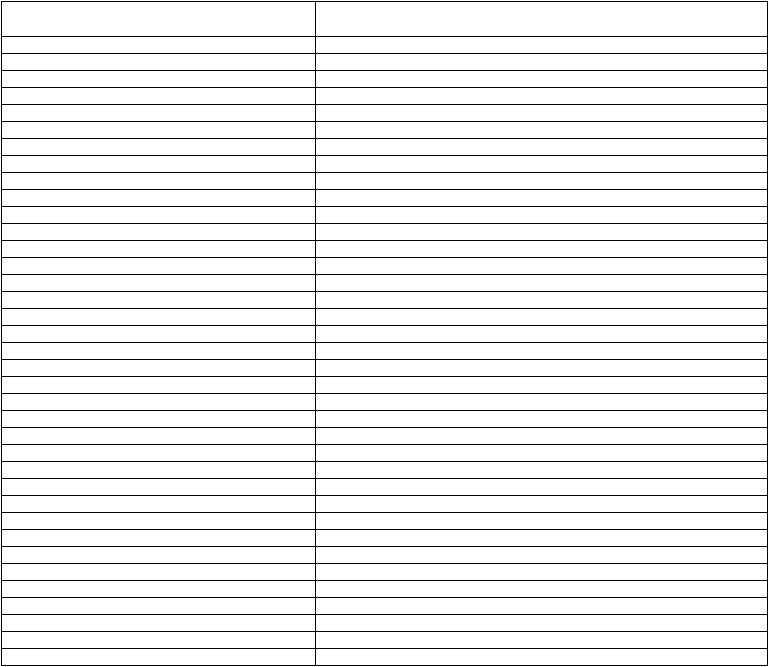

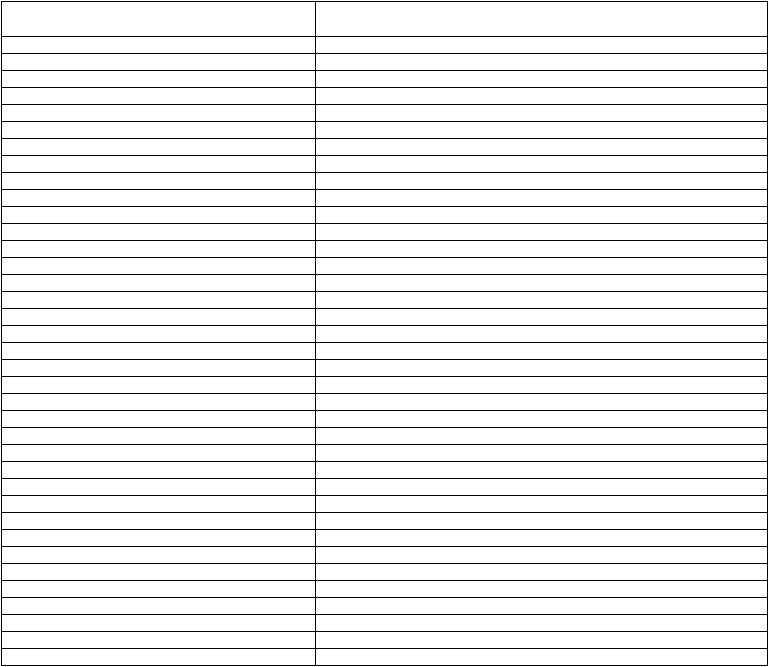

Table 3-2. Penetrant Inspection Materials

MIL-1-25135D

DESCRIPTION

DESIGNATION

TYPE I

FLUORESCENT DYE PENETRANT

TYPE II

VISIBLE DYE PENETRANT

TYPE III

VISIBLE AND FLUORESCENT PENETRANT (DUAL MODE)

METHOD A

WATER WASHABLE (WW)

METHOD B

POST EMULSIFIABLE, LIPOPHILIC

METHOD C

SOLVENT REMOVABLE

METHOD D

POST EMULSIFIABLE, HYDROPHILIC

SENSITIVITY LEVEL 1.

LOW SENSITIVITY

SENSITIVITY LEVEL 2.

MEDIUM SENSITIVITY

SENSITIVITY LEVEL 3.

HIGH SENSITIVITY

SENSITIVITY LEVEL 4

ULTRA-HIGH SENSITIVITY

FORM a.

DRY POWDER DEVELOPER

FORM b.

WATER SOLUBLE DEVELOPER

FORM c.

WATER SUSPENDABLE DEVELOPER

FORM d.

NONAQUEOUS (WET) DEVELOPER

FORM e

SPECIFIC APPLICATION NON-AQUEOUS WET DEVELOPER

CLASS (1.)

HALOGENATED SOLVENT REMOVER

CLASS (2)

NON-HALOGENATED SOLVENT REMOVER

CLASS (3)

SPECIFIC APPLICATION SOLVENT REMOVER

(3)

Steam cleaning Steam cleaning is a modification of the hot-tank, alkaline-cleaning method which can be

used for preparation of large unwieldy parts

(4)

Vapor degreasing. Vapor degreasing is a highly preferred method of cleaning, especially when heavy oils

and grease may fill surface defects Inorganic contamination is generally best removed by the alkaline cleaning process,

but organic soils often respond better to vapor degreasing.

(5)

Ultrasonic cleaning. When cracks are filled with some hard contaminate such as oxide, carbon, or engine

varnish, ultrasonic cleaning may be used to break up (or remove) these contaminates in order that the dye penetrant may

enter.

3-14