TM 1-1500-204-23-9

CAUTION

After assembling die to diestock, ensure that the

setscrew is tight. The die could fall out of the diestock,

causing damage to the die.

(b)

Assemble the die to the diestock

and

tighten the setscrew.

WARNING

Dry-cleaning solvent is flammable and solvent vapors

are toxic. Use P-D-680, Type II Solvent in a well-

ventilated area. Keep away from open flames. Avoid

prolonged solvent contact with skin.

(c)

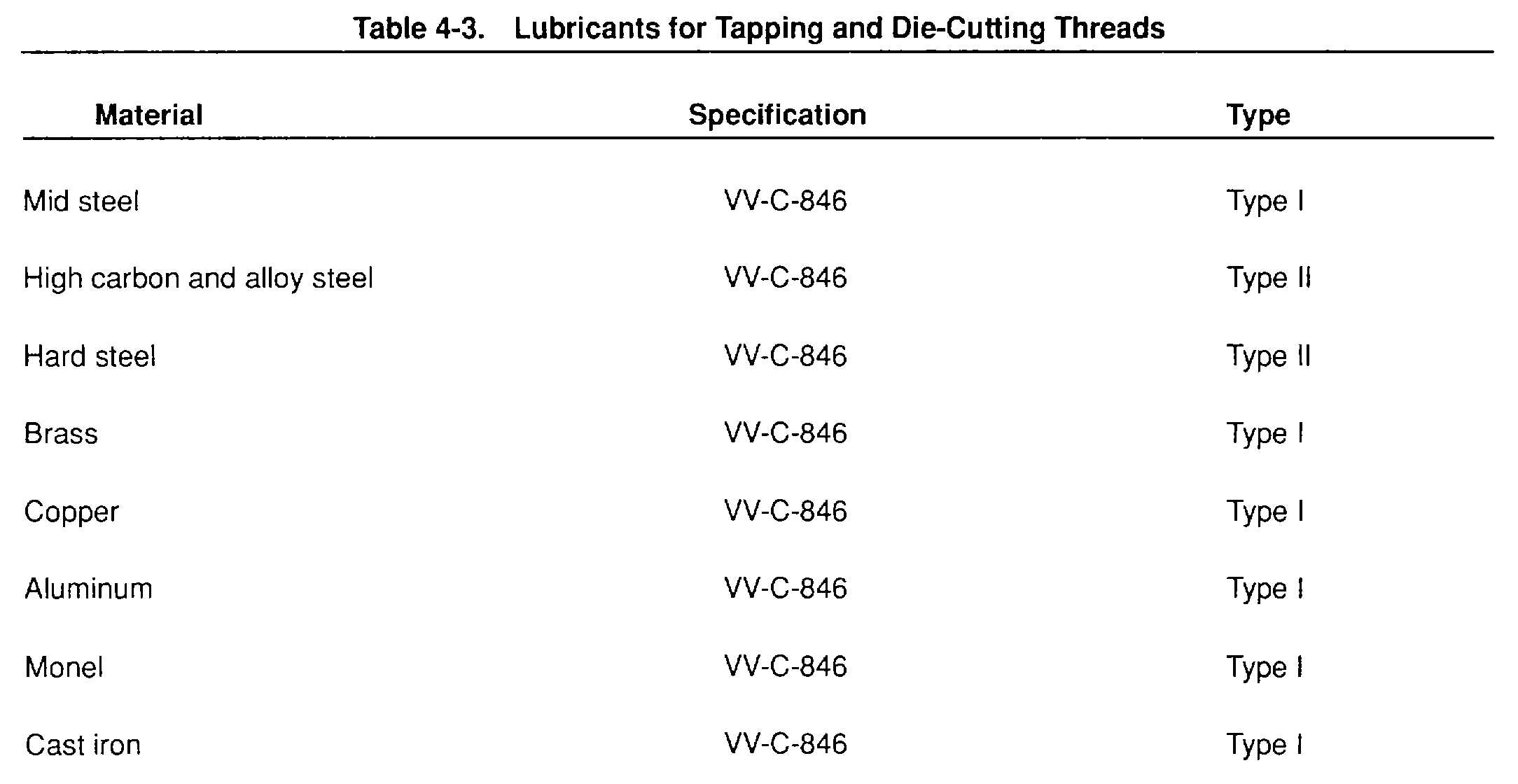

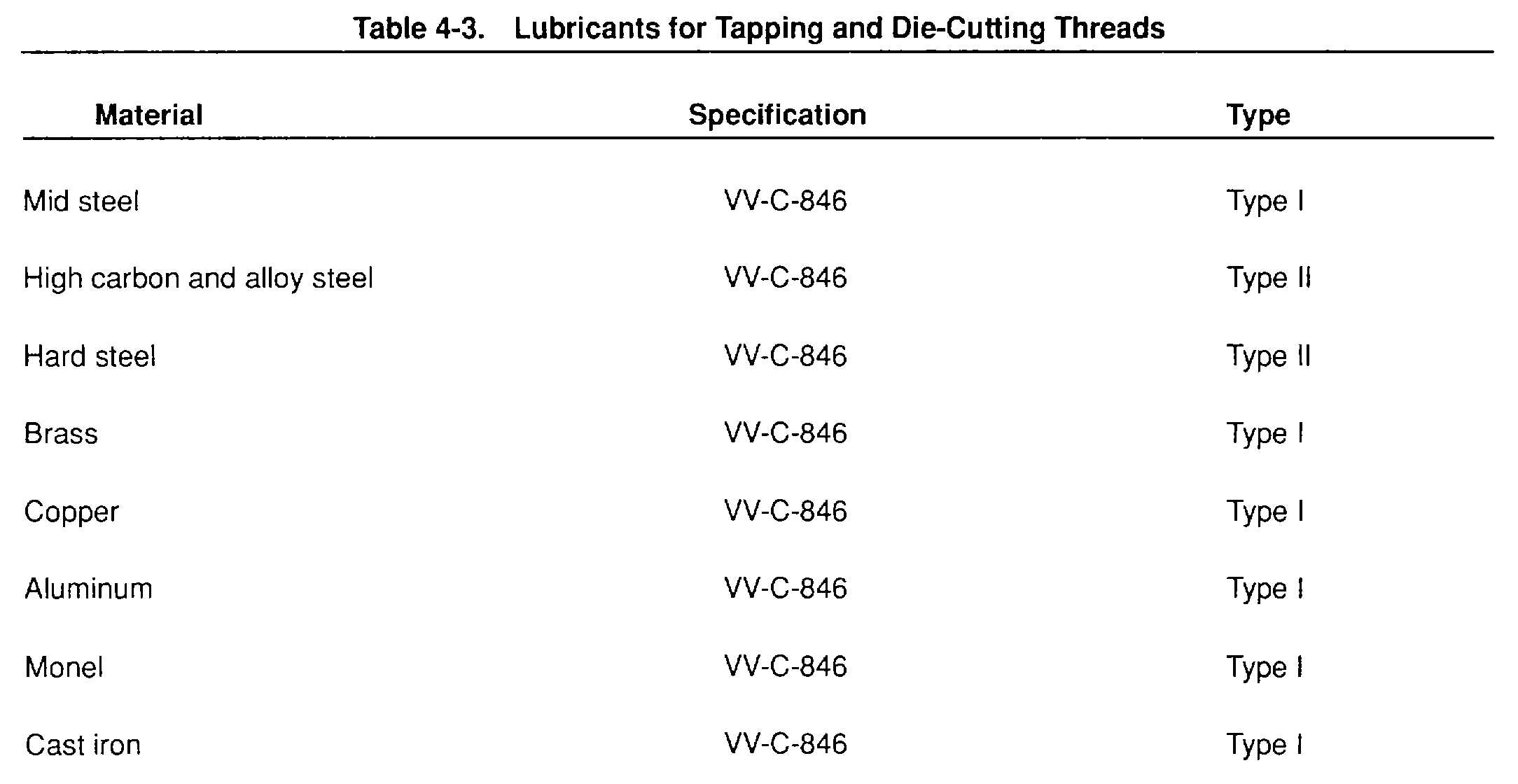

Use a cutting oil from table 4-3 which

corresponds to the type of metal being threaded.

CAUTION

Do not attempt to cut a thread with a die which has a

major diameter smaller than the diameter of the part to

be cut.

(d)

Position the diestock over the work and

tighten the thumbscrews to secure the diestock to the

work.

(e)

Rotate the diestock slowly but firmly, until

the die takes hold.

(f)

Turn the die backwards about 1/4 turn for

every full revolution forward in order to break off the

chip and make cutting easier.

(g)

When the desired length of thread has

been cut, slowly back the diestock off the work.

(h)

Clean the threads with a clean rag and

check with a thread gauge before installing.

(3)

Diestocks. Figure 4-105 shows the

ordinary and ratchet-type diestocks normally used with

dies. The ratchet-type diestocks are usually used with

rectangular pipe dies.

(4)

Care. Observe the following practices for

the care and upkeep of dies:

(a)

Do not attempt to sharpen dies.

(b)

Keep cutting edges lightly oiled.

(c)

Wipe excess oil and metal shavings from

dies and diestocks.

Table 4-3. Lubricants for Tapping and Die-Cutting Threads

4-42