TM 1-1500-204-23-9

(1)

Insert the drill bit into the drill chuck.

(2)

Install an air hose to the air inlet

connection.

NOTE

A drill bit that wobbles or is slightly bent

should not be used because it will cause

enlarged holes.

(3)

Test the drill bit for trueness and vibration

by running the drill freely.

WARNING

Wear

eye

protection

when

drilling.

Failure to comply may result in serious

injury to personnel.

(4)

Always hold the drill at right angles to the

work regardless of the position or curvatures. Tilting the

drill at any time may cause elongation of the hole.

c.

Care. Consult the applicable operator's and

service manuals for inspection and maintenance

procedures for pneumatic drills.

5-8.

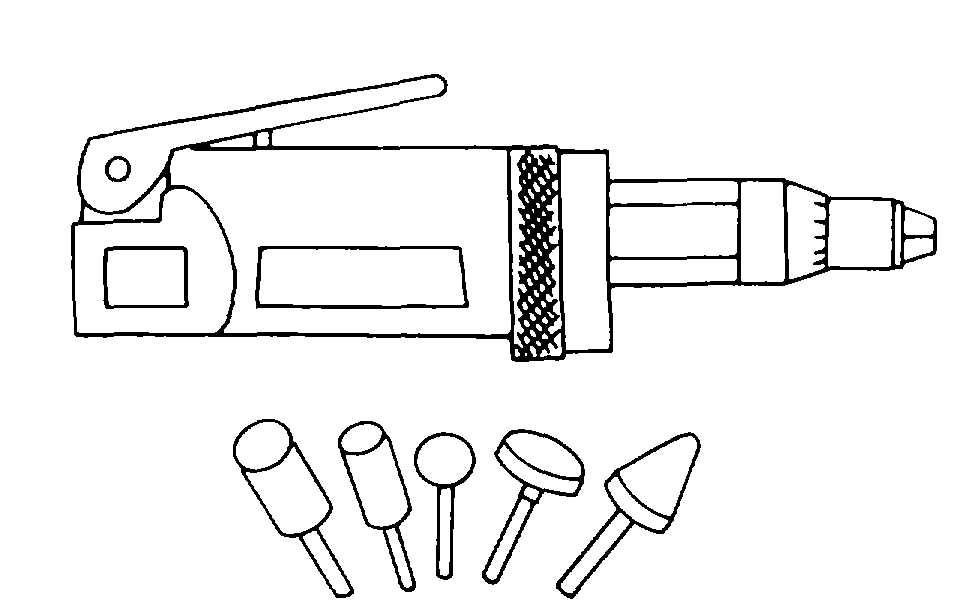

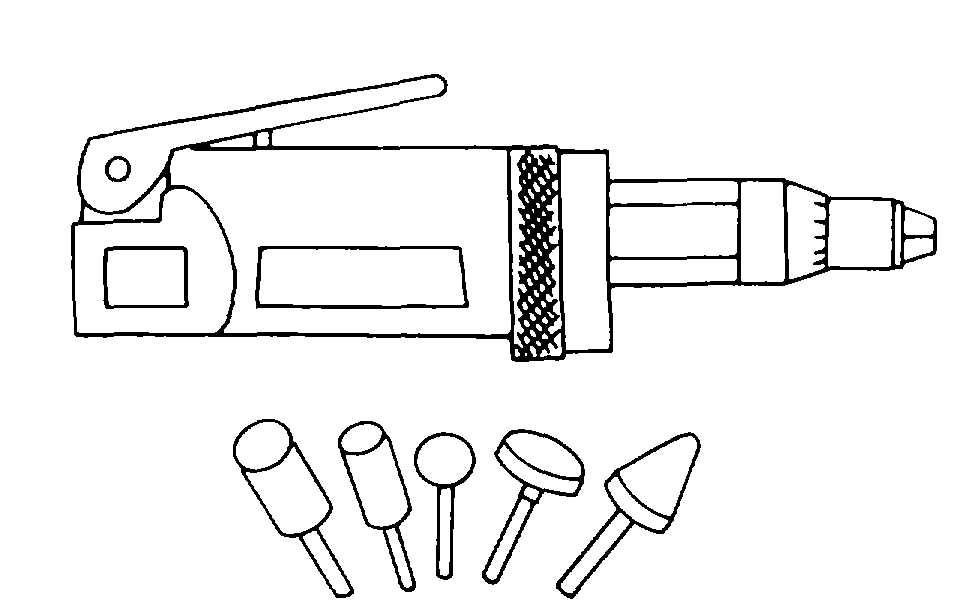

Pneumatic Grinder. A pneumatic grinder is

used where electrical power is not available or where

sparks from an electric motor could be a fire hazard.

a.

Types. A typical pneumatic grinder is shown in

figure 5-16. The grinders are rated by no-load speeds,

which typically result in terms of light-, medium-, and

heavy-duty loads being used to describe the grinder.

The grinding stones come in numerous shapes and give

versatility to the grinder.

Figure 5-16. Pneumatic Grinder

b.

Use. Procedures for using pneumatic grinders

are as follows:

(1)

Insert the grinding stone into the chuck.

(2)

Install an air hose to the air inlet

connector.

NOTE

A grinding stone that wobbles or has a

bent shaft should not he used.

(3)

Test the grinding stone for trueness and

vibration by running the grinder freely. Grinding stones

which are glazed, out of true or out of round may be

reshaped with a dressing stick.

WARNING

Wear eye protection when grinding.

Failure to comply may result in serious

injury to personnel.

(4)

Perform grinding operations by holding

the grinder so that the proper edge of the grinding stone

is against the work.

c.

Care. Consult the applicable operator's and

service manuals for inspection and maintenance

requirements.

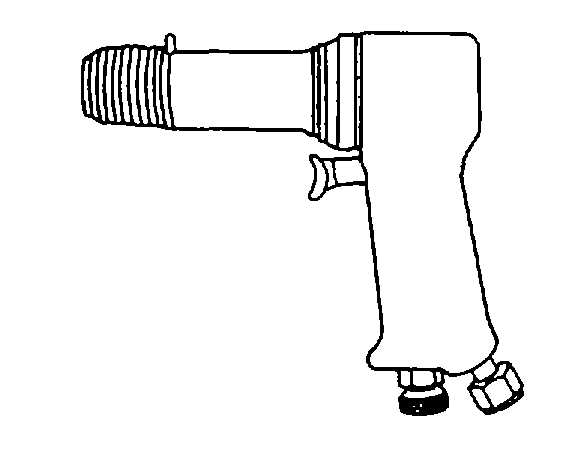

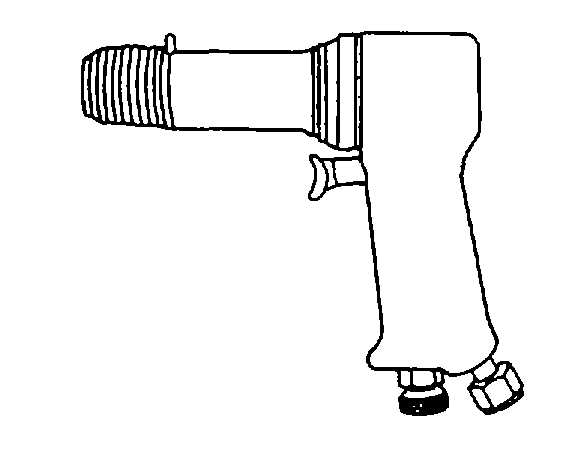

5-9.

Pneumatic Hammer. The pneumatic hammer,

shown in figure 5-17, is used for heavy-duty cutting,

shearing, punching, and chiseling and breaking joints.

The built-in air regulator varies speed and power.

Pneumatic hammers have strokes varying from 1 1/2 to

3 1/2 inches, at 2,000 to 4,500 blows per minute. This

hammer uses insertable chisels with different end

shapes, such as tapered punch, panel cutter, cut-off,

and weld buster.

Figure 5-17. Pneumatic Hammer

5-8