TM 1-1500-204-23-9

NOTE

A 0.002 to 0.005 inch clearance should

be

provided.

This

may

be

accomplished by scraping or reaming

the lead bushing in the center of the

wheel.

(5) Mount the wheel on the shaft, and ensure that it

fits without play.

(6) Install another blotter and then the outer flange.

(7) Install the washer and the nut.

CAUTION

Do not overtighten the spindle nut.

Failure to comply may result in cracking

of the grinding wheel.

(8) Tighten the nut sufficiently to hold the wheel

firmly.

(9) Operate the grinder for a minute or two in order

to test for breakage.

WARNING

·

Always wear safety goggles when

using grinder. Failure to comply

may result in serious bodily injury.

·

Ensure that the abrasive wheels are

firmly attached to the spindles by

the flange nuts. If a wheel should

loosen or detach, serious bodily

injury could result.

·

Ensure that tool rests are firmly in

place. A loose tool rest could cause

the tool or piece of work to be

grabbed by the wheel and cause the

hand of the operator to contact the

wheel. Serious bodily injury may

result.

e. Dressing and Truing. Grinding wheels, like other

cutting tools, require frequent reconditioning of cutting

surfaces to perform efficiently. Dressing is the term

used to describe the process of cleaning the periphery

of grinding wheels. This cleaning breaks away dull

abrasive grains and smooths the surface so that there

are no grooves. Truing is the term used to describe the

removal of abrasive from the cutting face of the wheel

so that the resultant surface runs absolutely true to

some other surface such as the grinding wheel shaft.

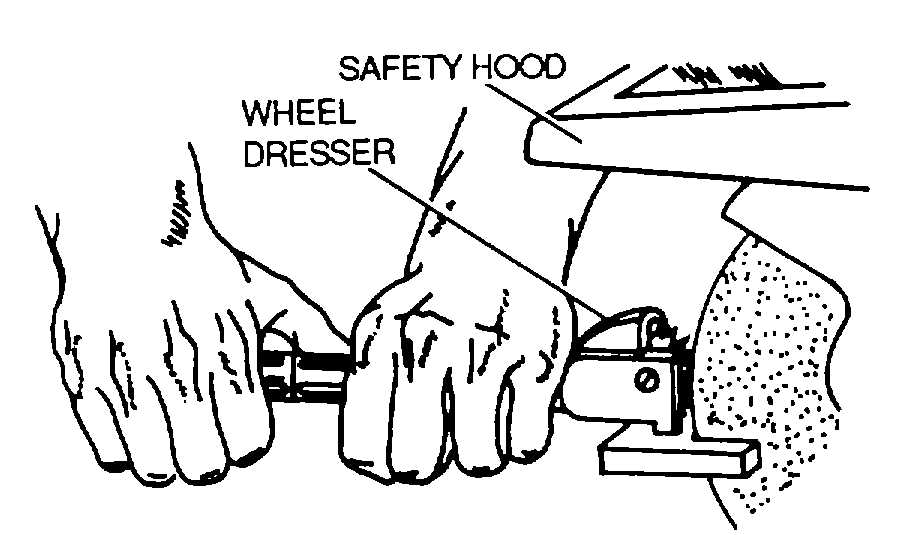

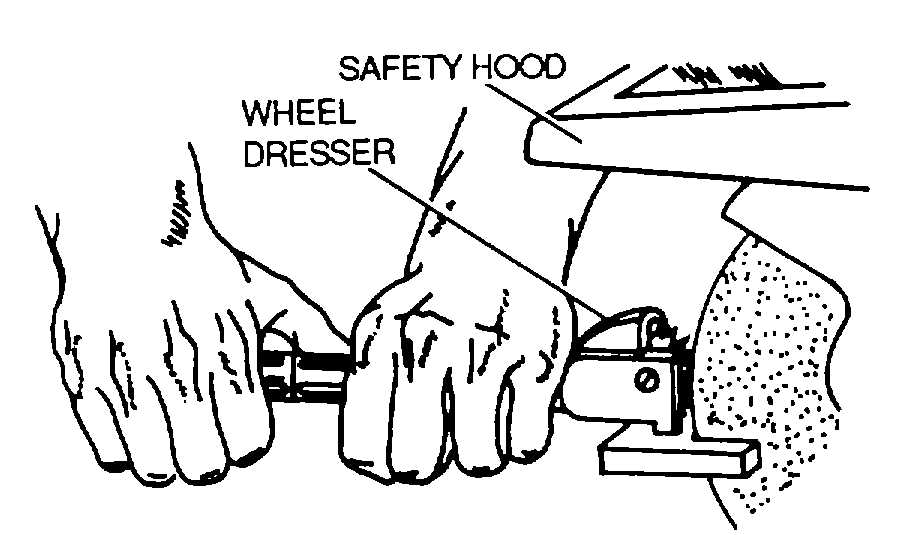

(1) Dressing procedure. To dress a wheel, proceed

as follows (see figure 6-6):

(a) Start the grinder and let it come up to speed.

(b) Set the wheel dresser on the tool rest as

shown in figure 6-6 and bring it in firm contact with the

wheel.

Figure 6-6. Dressing a Grinding Wheel

(c) Move the wheel dresser back and forth across

the face of the wheel until the surface is clean and

approximately square with the sides of the wheel.

(2) Wheel re-balancing. If grinding wheels get out

of balance because of out-of-roundness, dressing the

wheel will usually remedy the condition. A grinding

wheel can get out of balance by being left sitting with

part of the wheel immersed in the coolant; if this

happens, the wheel should be removed and dried out by

baking. If the wheel gets out of balance axially, it

probably will not affect the efficiency of the wheel. This

unbalance may be remedied simply by removing the

wheel and cleaning the shaft spindle and spindle hole in

the wheel and the flanges.

WARNING

Do not attempt to make any adjustment

to the tool rest until the grinder is shut

down

and

the

power

disconnected.

Failure to comply may result in serious

injury to the operator.

6-5