TM 1-1500-204-23-9

CHAPTER 6

ELECTRICAL POWER TOOLS

6-1.

General. The power tools described within this

chapter are of the common types used to accomplish

jobs in an efficient manner with less time involved.

These tools are usually used in a shop environment,

although they can be used in the field with an adequate

power supply.

WARNING

Electric drills are not to be used on aircraft due to spark

hazard.

6-2.

Safety. The following safety precautions will be

followed when operating electric power tools:

a.

Never operate power tools unless they are

completely understood. When in doubt, consult the

applicable operator's manual.

b.

Inspect all power tools before use to ensure

their serviceable condition.

c.

Prior to connecting the tool to its power source,

ensure that the power switch is in the OFF position.

d.

Keep all safety guards in position and wear

safety shields or goggles when necessary.

e.

Fasten all loose clothing and aprons.

f.

Never try to clear jammed machinery before

disconnecting the tool from its power source.

g.

Before plugging a tool into a power source,

ensure that the power source provides the correct

voltage

required by the tool.

h.

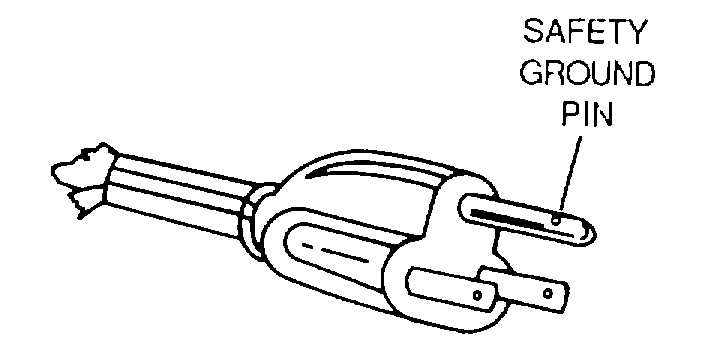

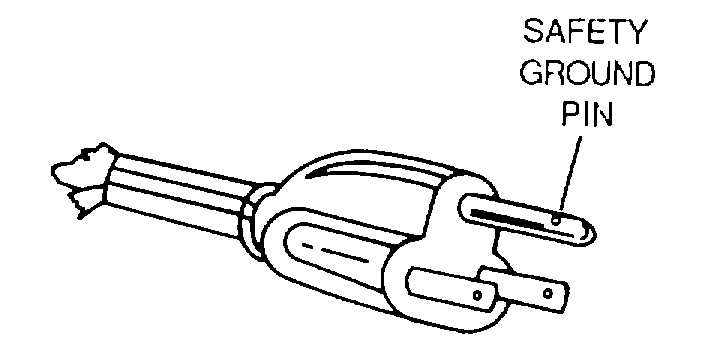

If the power cord has a ground pin as shown in

figure 6-1, do not attempt to use it with an adapter. The

ground pin serves to decrease the possibility of electric

shock.

i.

Do not use sparking electric tools in places

where flammable gases or liquids or exposed explosives

are present. Use pneumatic tools in these areas.

Figure 6-1. Three-Prong Grounded Plug

j.

Ensure that power cables are cared for

according to the following precautions:

(1)

Do not allow power cords to come in

contact with sharp objects, oil, grease, chemicals, or hot

surfaces.

(2)

Replace cords when they are damaged.

(3)

Ensure that the power cord is of sufficient

length so that it will not be pulled taut to reach the work

location.

(4)

Position power cords so that they will not

be tripping hazards.

6-3.

Electric Drills. The electric drill is a hand tool

driven by a small, high-speed electric motor. The motor

is geared to the chuck through reduction gears. The

components of the drill are enclosed in a metal or plastic

pistol grip case to permit ease of handling. Although it

is specially designed for drilling holes, it can be adapted

for different jobs by the addition of various accessories.

It can be used for sanding, buffing, polishing, wire

brushing, and paint mixing. Typical electric drills are

shown in figure 6-2.

a.

Sizes. The sizes of electric drills are classified

by the largest straight shank drills that they will hold.

Therefore, a 1/4 inch drill will hold straight shank drills

up to and including 1/4 inch, and a 3/8 inch drill will hold

bits up to and including 3/8 inch.

b.

Speed. The drill is made to run at speeds which

will prevent the motor from burning out. For this reason,

large drills run at slower speeds than smaller drills. This

is because larger drills are designed to turn larger

6-1