TM 1-1500-204-23-9

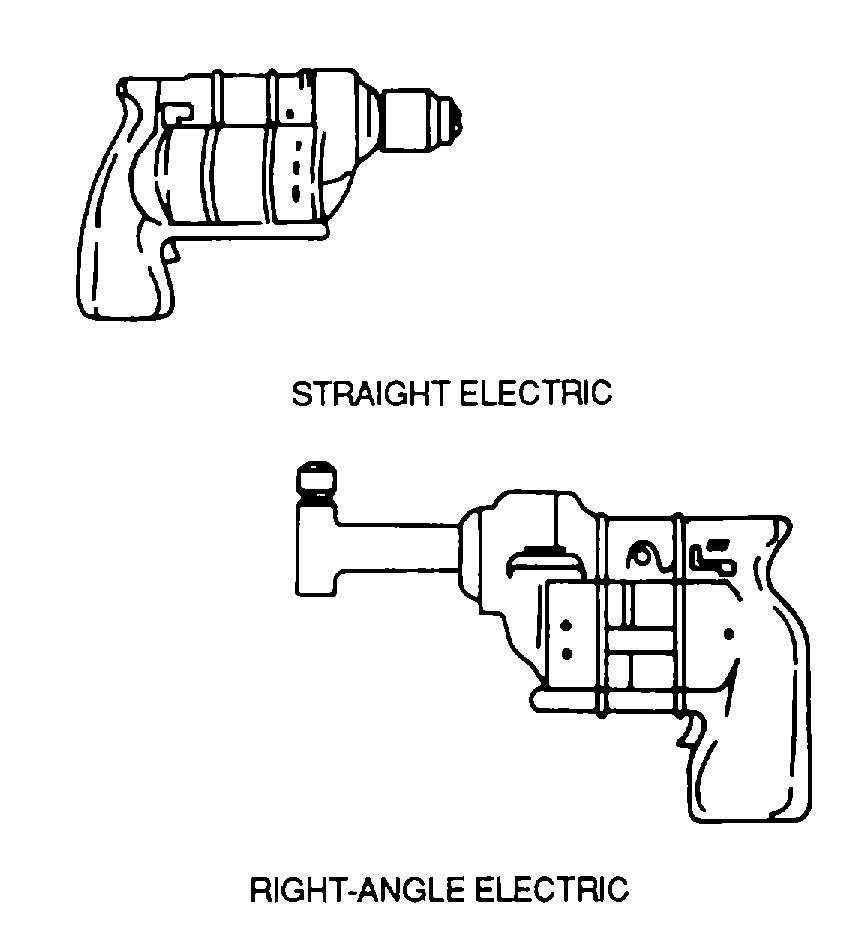

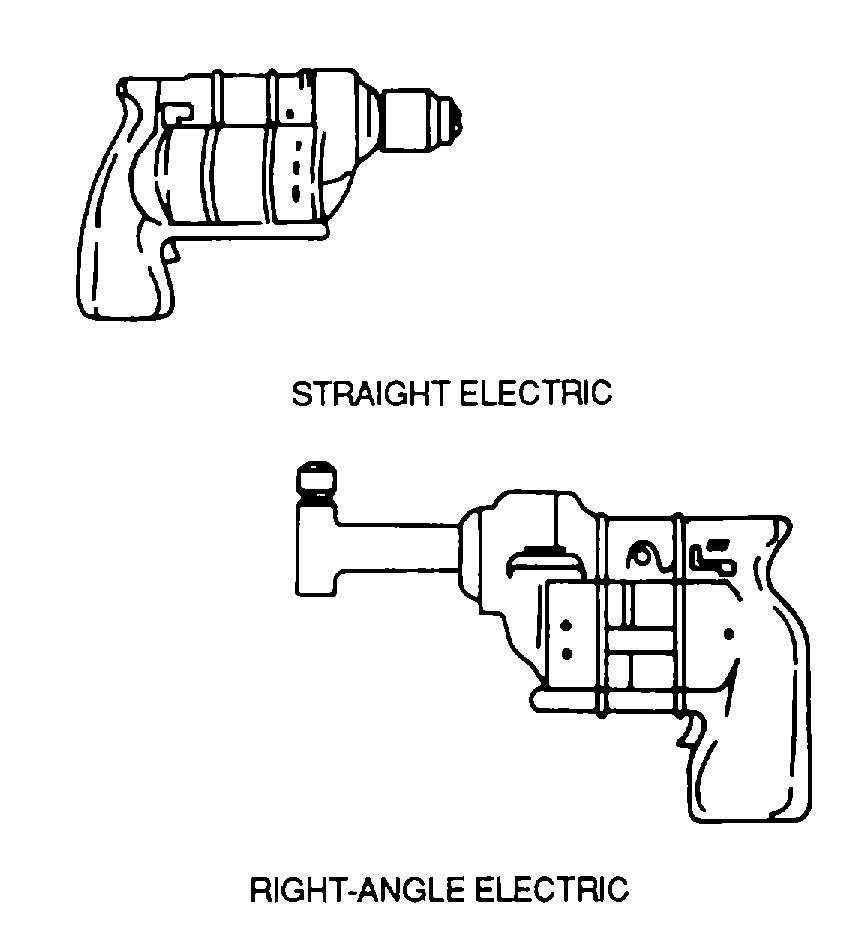

Figure 6-2. Electric Drills

cutting tools or to drill heavy stock, both of which require

a slower speed. Therefore, to drill in a metal such as

steel, a 3/8 or 1/2 inch drill should be used, whereas for

drilling holes in wood or sheet metal, a 1/4 inch drill will

be sufficient.

c.

Use The operation of an electric drill involves

installing the drill bit and operating the drill.

(1)

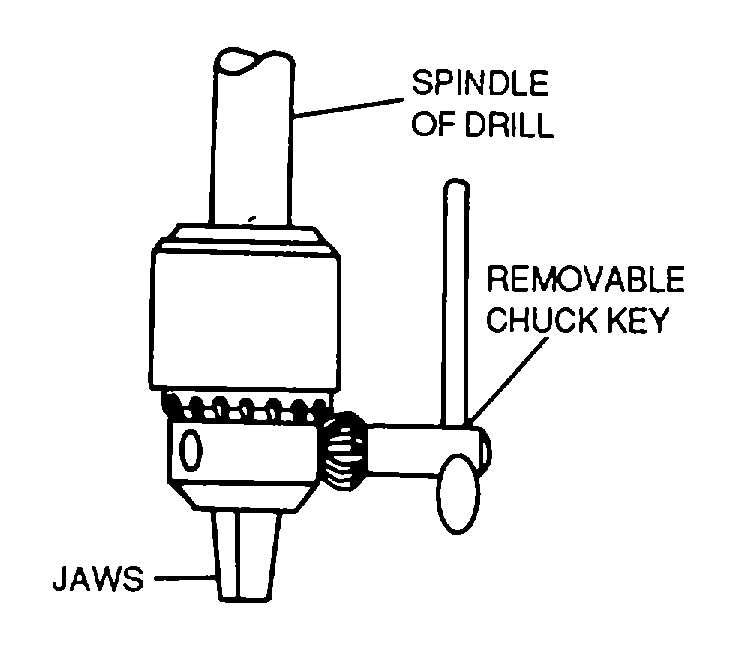

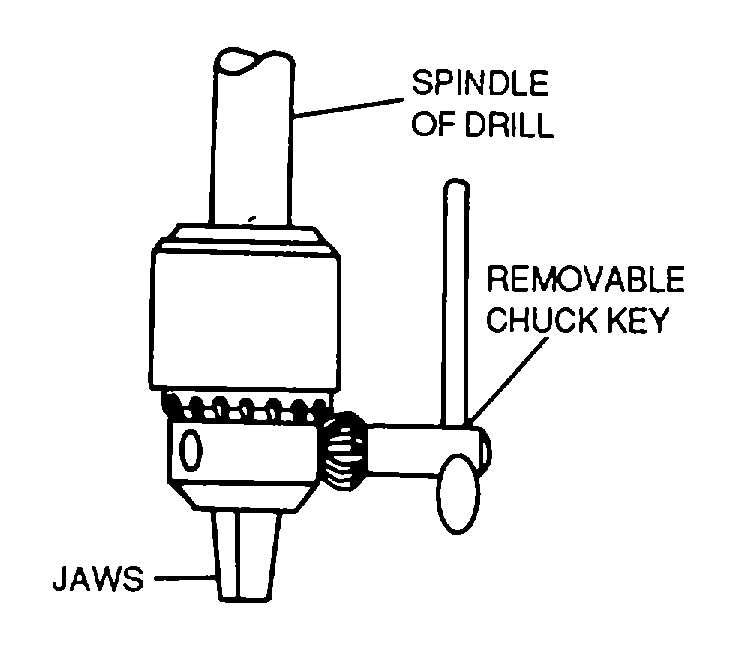

Installing the drill bit. The drill bit is

installed in the chuck on the drill. Nearly all electric

drills are equipped with a three-jaw chuck, which is

tightened and loosened by means of a chuck key, as

shown in figure 6-3.

NOTE

· Do not apply further pressure with pliers

or wrenches after the chuck is hand-

tightened with the chuck key.

· Always remove the key immediately after

it is used. Otherwise, the key will fly loose

when the drill motor is started and may

cause serious injury to personnel.

(2)

Operating the drill. Stock is drilled as

outlined in paragraph 4-13 of this volume or in TM

11500-204-23-10.

Figure 6-3. Three-Jaw Chuck and Chuck Key

d.

Care. Consult the applicable operator's manual

for procedures for maintenance and inspection of

electric drills.

6-4.

Electric Grinders. To keep hand tools in the best

usable condition, cutting edges must be sharpened

frequently and certain other tools trued or shaped for

special purposes. Chisels, punches, drills, snips,

screwdrivers, and other hand tools are shaped or

sharpened on a grinder. There are two basic types of

grinders: a bench type and a pedestal type. These

grinders, shown in figure 6-4, consist of an electric

motor with a grinding wheel attached to each end of the

motor shaft. One wheel is coarse, for rough work; the

other is fine and is used for sharpening purposes.

a.

Grinding Safety. The grinding wheel is a fragile

cutting tool which operates at high speeds. Great

emphasis must be given, therefore, to the safe

operation of bench and pedestal grinders. The following

procedures are mandatory safety precautions for the

safety of the operator and the safety of personnel in the

nearby vicinity:

(1)

Secure all loose clothing and remove

rings and other jewelry.

(2)

Inspect the grinding wheel, wheel guards,

toolrest, and other safety devices to ensure that they are

properly installed and in serviceable condition.

6-2