TM 1-1500-204-23-9

(3)

Hardness. Hardness of a grinding wheel

is a measurement of the ability of the bond to retain the

abrasive grains in the wheel. Grinding wheels are said

to have a soft to hard grade, which indicate the wheel

has a large amount of bond (hard) or a small amount of

bond (soft).

c.

Types of Grinding Wheels. The selection of

grinding wheels for precision grinding can be discussed

generally in terms of such factors as the physical

properties of the stock to be ground, the amount of stock

to be removed (depth of cut), the wheel speed and work

speed, and the finish required. Selection of a grinding

wheel is determined by considering one or more of

these factors. The following paragraphs describe the

types of wheels which can be used to grind metals with

certain general qualities.

(1)

Wheel abrasive type. An aluminum oxide

abrasive is most suitable for grinding carbon and alloy

steel, high speed steel, cast alloys and malleable iron. A

silicon carbide abrasive is most suitable for grinding

nonferrous

metals,

nonmetallic

substances,

and

cemented carbides.

(2)

Wheel coarseness. Generally, the softer

and more ductile the substance being ground, the

coarser the grain selected should be. Also, if a large

amount is to be removed, a coarse grain wheel is

recommended (except on very hard objects). If a good

finish is required, a fine grain wheel should be used.

(3)

Wheel hardness. For soft metals, small

depth of cut, or high work speed, use a soft grade wheel.

If the machine you are using is worn, a harder grade

may be necessary to help offset the effects of wear of

the machine. Using a coolant also permits the use of a

harder grade of wheel.

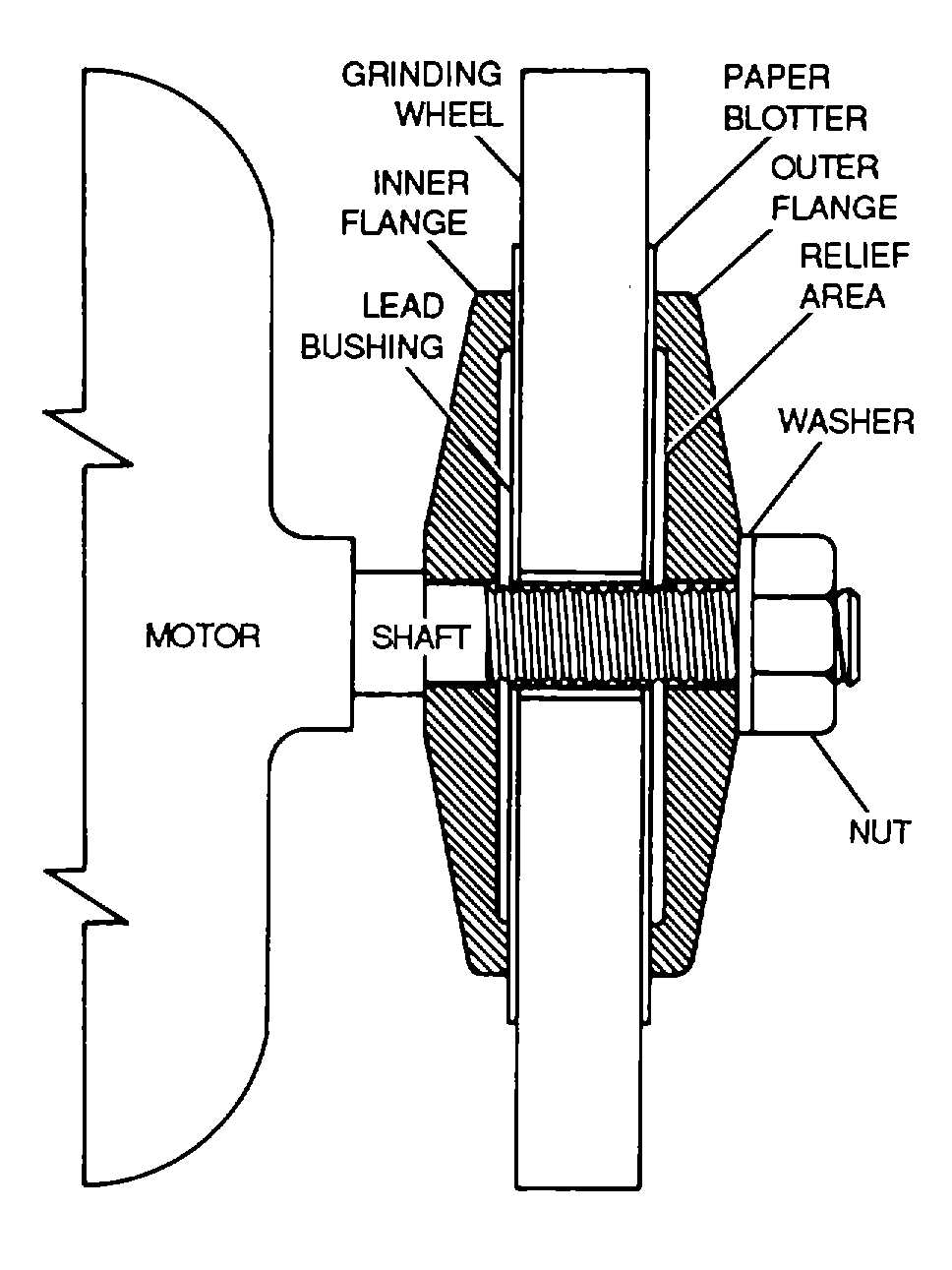

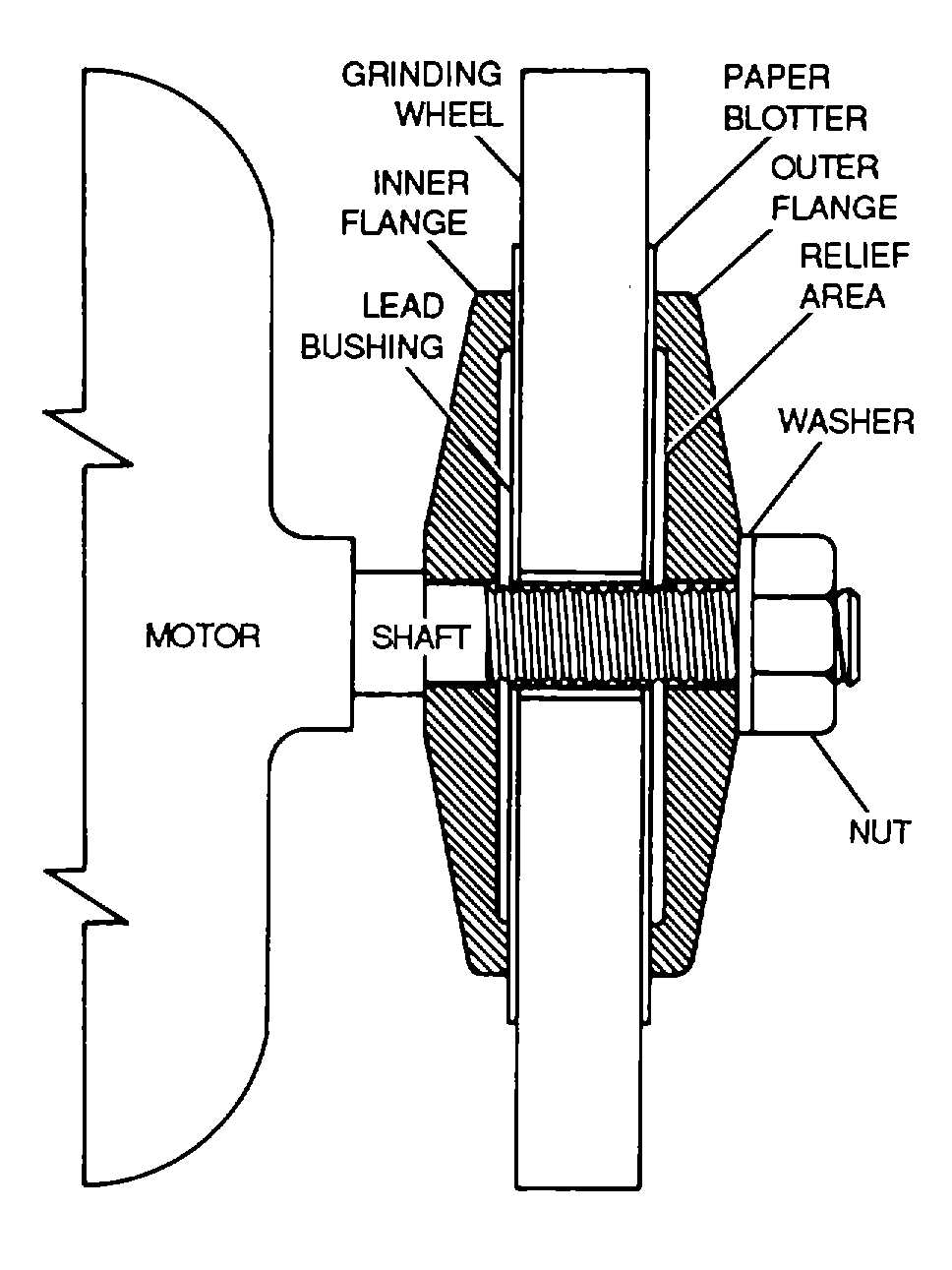

d.

Wheel Installation. The wheel of a grinder must

be properly installed. If it is not, the wheel may operate

improperly, and an accident may occur. Install a grinder

wheel as follows (see figure 6-5):

CAUTION

Do not use a metallic object for testing

the soundness of a grinding wheel. The

wheel may crack and disintegrate at any

time.

(1)

Test the wheel for soundness by tapping it

lightly with a piece of hard wood. A good wheel gives

out a clear, ringing sound when tapped. If the wheel is

cracked, a dull thud will be heard.

Figure 6-5. Grinding Wheel Installation

(2)

Ensure that the shaft and flanges are

clean and free of grit and old blotter.

(3)

Install the inner flange on the shaft.

NOTE

The blotter thickness for paper must be

no thicker than 0.025 inch. A leather or

rubber blotter must be no thicker than

0.125 inch.

(4)

Place a blotter on the shaft and up against

the flange to ensure even pressure on the wheel, and to

dampen the vibration between the wheel and the shaft.

CAUTION

Never force the wheel on the shaft. This

may cause the wheel to crack, or be out

of alignment.

6-4