TM 1-1500-204-23-9

7-14 Change 4

h.

If the safety cable does touch the wall of the

fixture, the tool should not be returned to service, and

must be adjusted or serviced. Follow the instructions in

the next section of this manual.

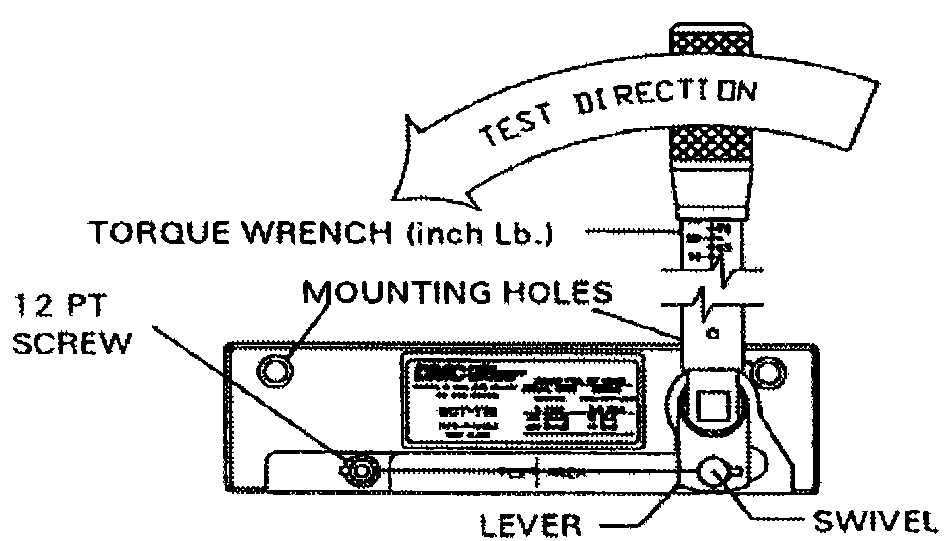

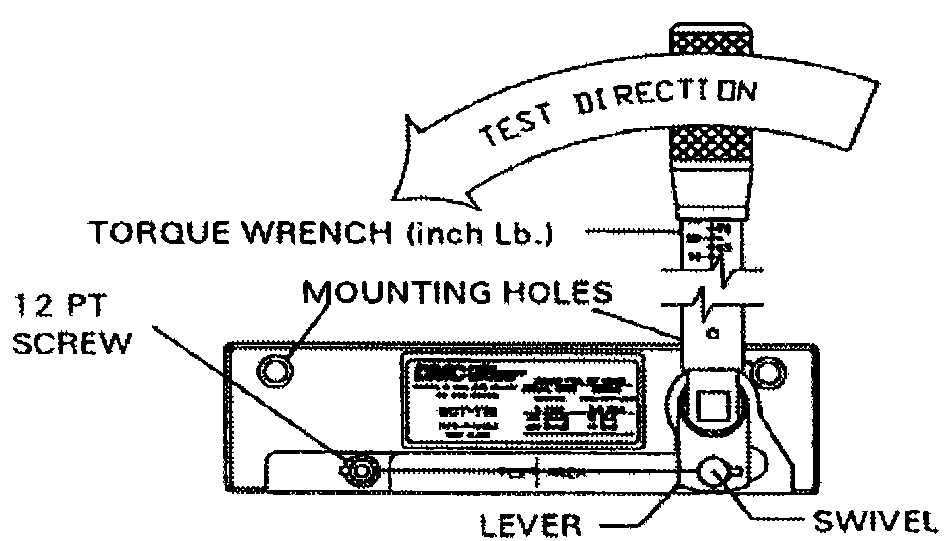

Figure 7-26. Torque Verification

Fixture and Torque Wrench

i.

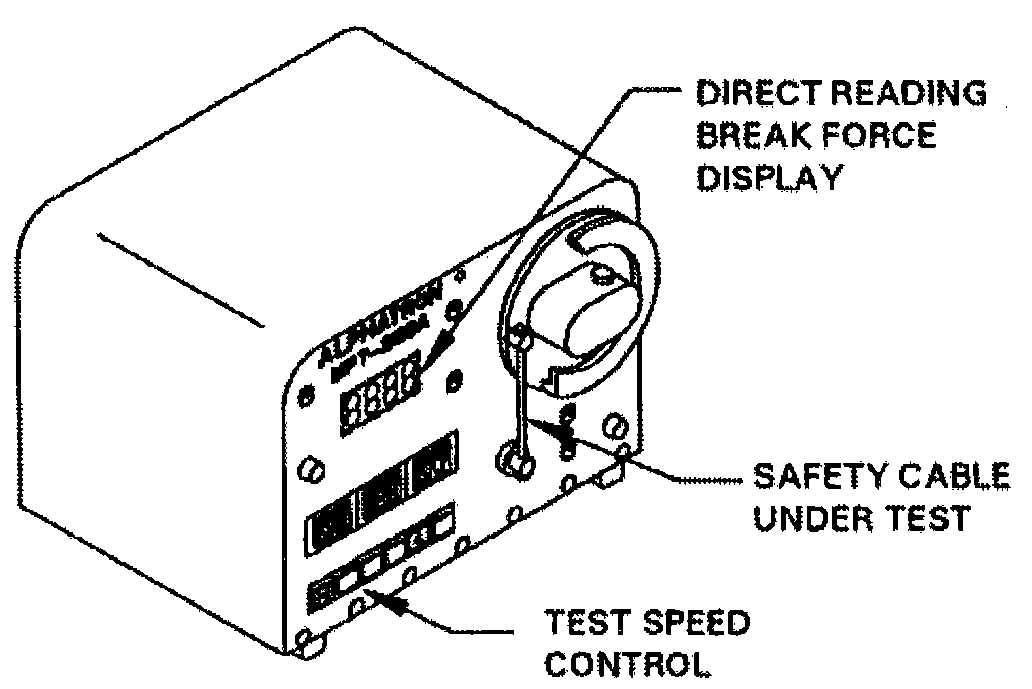

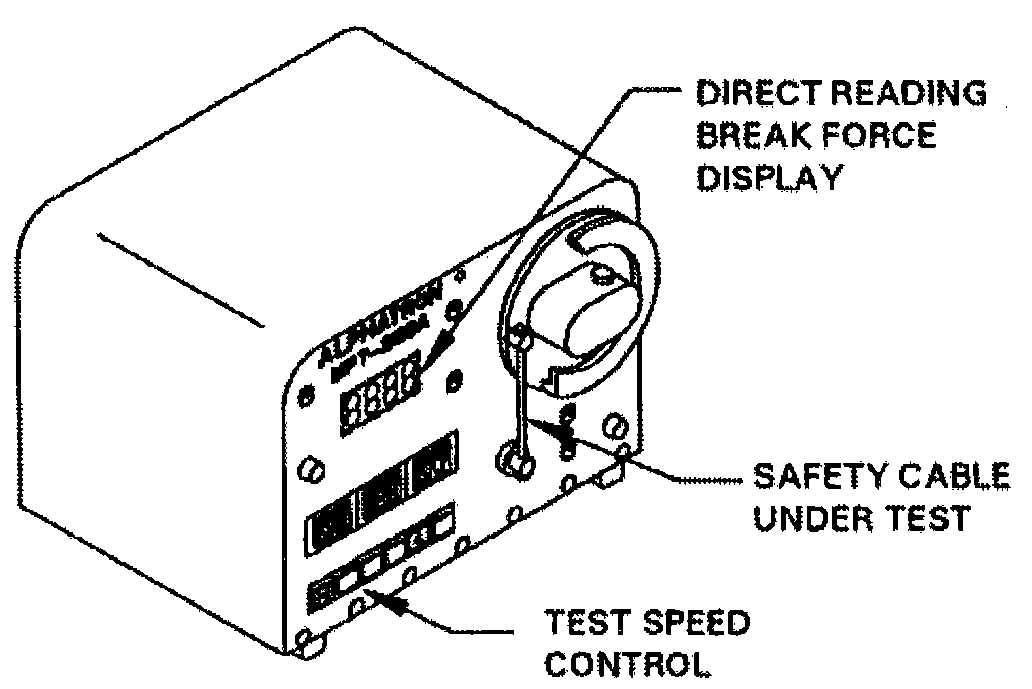

Tool calibration verification with an electronic

tester. It may be required in some applications to use an

electronic pull tester to test safety cable to destruction. If

this is required, the tester (Figure 7-27) should have digi-

tal readout capability, and a two (2) inch/minute pull rate.

Figure 7-27. Electronic Safety Cable

Pull Tester

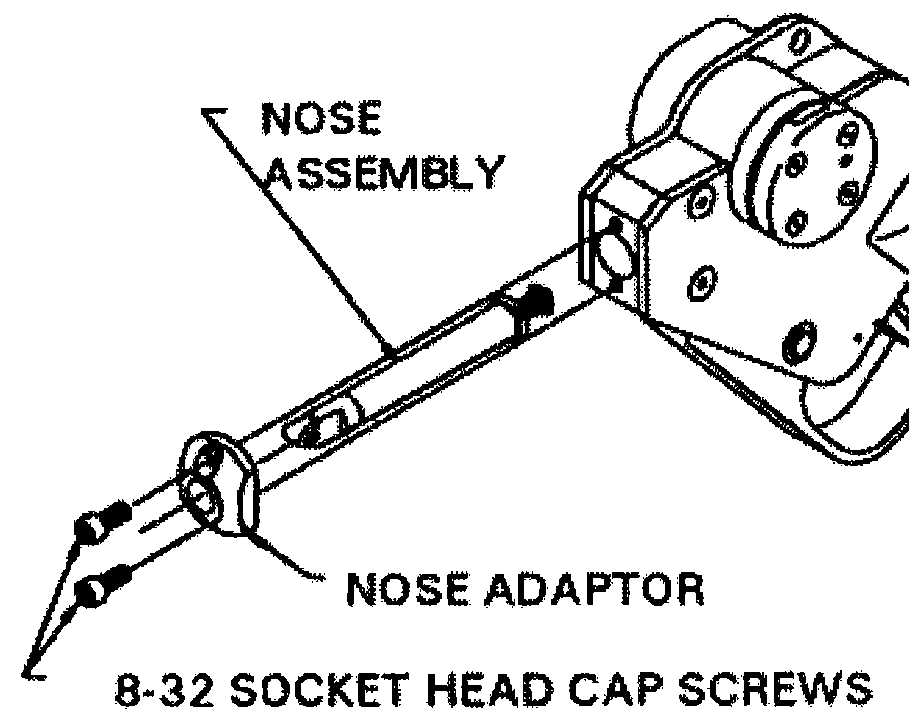

j.

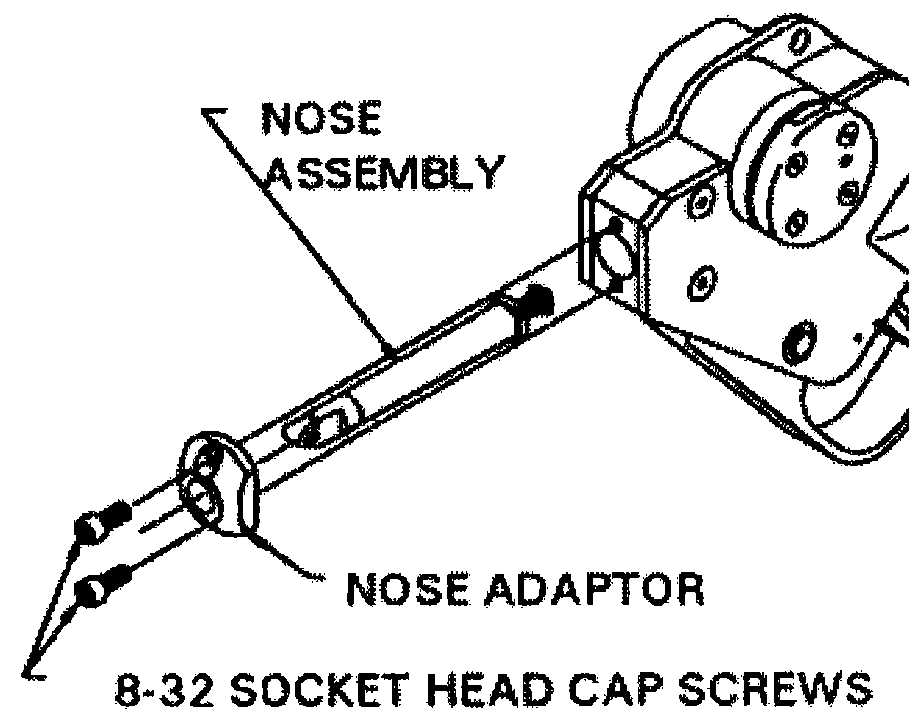

Safety Cable tool Indenter Adjustment/Calibra-

tion. Remove the nose assembly by removing the two

8-32 socket head cap screws with a 9/64 inch hex wrench

(see Figure 7-28).

Figure 7-28. Removal of Safety Cable

Tool Nose Assembly

k.

Unlock the jamnut using the SCT32084 tool

(supplied by the manufacturer). Adjust the pushrod

adjustment screw using a 1/4 inch straight edge screw-

driver (see Figure 7-29). Turn the screw clockwise to

loosen the crimp (enlarge the gaging dimension), or

counterclockwise to tighten the crimp (reduce the gaging

dimension). After each adjustment, securely tighten the

jam nut using the SCT32084 tool (while holding the

adjustment screw tight with the screwdriver). Reinstall

the tool nose being sure to tighten the 8-32 socket cap

screws securely.

CAUTION

Do not adjust the pushrod

adjustment screw more than

one quarter turn at a time. Radi-

cal adjustments may cause

damage to the tool.

l.

Retest the tool using the procedures previously

defined. Accept or reject the tool on the basis of the

pass/fail criteria stated above, and repeat adjustment

process if necessary to achieve passing results.