TM 1-1500-204-23-9

Change 4 7-13

c.

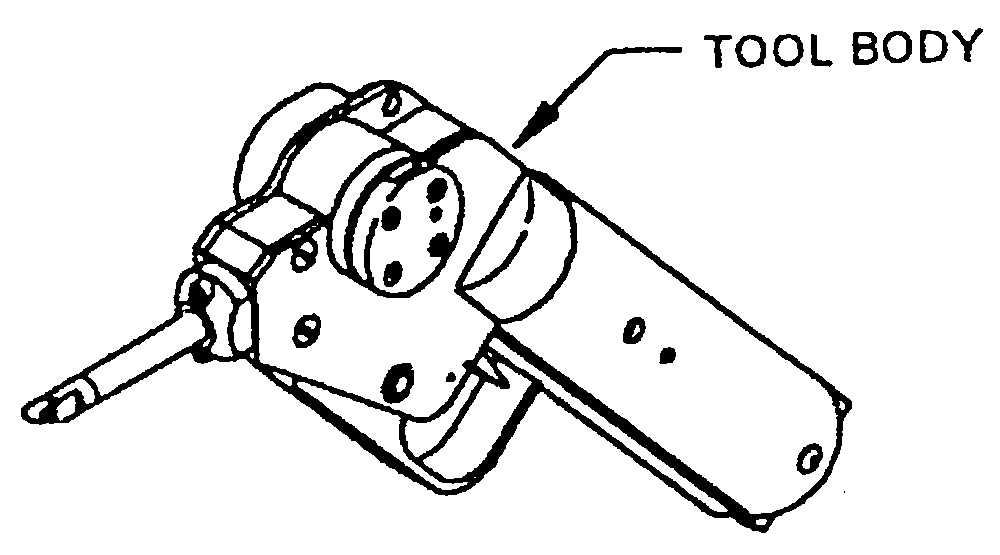

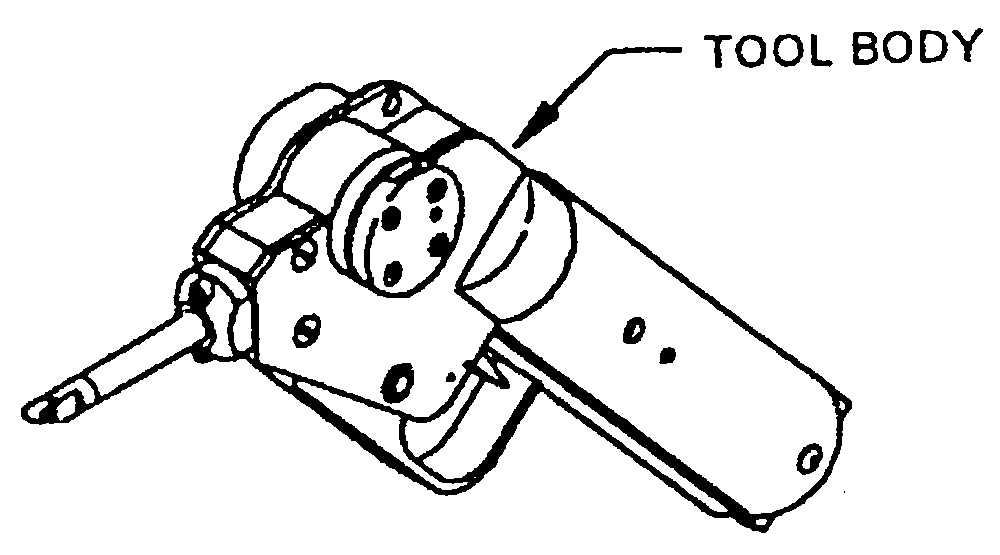

Pneumatic Safety Cable Tool. (Figure 7-25.)

Confirm that the tool is set-up correctly and calibrated.

Connect the pneumatic safety cable application tool to a

clean dry air supply of 80 to 100 psi.

(1)

Install the safety cable through the compo-

nents, which are to be secured.

(2)

The tool nose can be rotated to any conve-

nient position.

(3)

Insert the free end of the cable through the

ferrule in the cartridge, and remove the ferrule by pulling

the cable away from the end of the cartridge. Insert the

free end of the cable through the nose of the tool, and

slide the tool along the cable to the desired position.

(4)

Rotate the cable tension wheel clockwise if

necessary to move the cable entry slot to an accessible

position. Align the nose such that the ferrule is pressed

square against the component being secured. Make cer-

tain the ferrule is fully seated in the tool nose. Insert the

free end of the cable into the cable entry slot of the cable-

tensioning wheel. When the end of the cable exits the

wheel, grip the slack from the cable. Do not leave more

than 1 1/2 inch of total slack in the cable.

(5)

Press the trigger and hold. The tool will

apply tension to the cable, crimp and cut. When the trig-

ger is released, the crimp mechanism will retract (after

the cycle is completed). The tool nose can then be

removed from the ferrule, and the excess cable dis-

carded.

Figure 7-25. Pneumatic Safety Cable

Application Tool

d.

Safety Cable Application Tool Maintenance and

Calibration. The safety cable tools should be stored in a

clean, dry place when not in use. Clean any debris (espe-

cially in the crimp cavity in the tool nose) from the tool with

a small brush and solvent if necessary. Lubricate the tool

nose (into the crimp cavity) with a drop of oil on a regular

basis.

e.

Tool calibration verification with the torque verifi-

cation fixture, or the electronic pull tester.

NOTE

Indenter calibration must be checked

frequently, and must be checked each

time the nose assembly has been

removed or changed.

f.

Use the torque verification fixture (Figure 7-26.)

and a calibrated torque wrench (0-155 inch-pound scale)

to verify the safety cable tool indenter adjustment.

Thread a new piece of safety cable into the torque verifi-

cation fixture and crimp a ferrule onto the cable with the

safety cable application tool being tested. This process

is the same for all hand and pneumatic tool models.

Apply approximately 2 pounds force to the cable with

your finger at the point marked ªtest areaº. The cable

should not touch the side of bottom wall of the fixture.

g.

Place a calibrated 3/8 inch drive torque wrench

(capable of indicating 30 inch-pounds for .020 cable, 70

inch-pounds for .032 cable, and 110 inch-pounds for .040

cable) into the square drive hole. Orient the verification

fixture and the torque wrench on a stable surface, slowly

and steadily apply the force until the required torque is

indicated. Do not apply additional pressure after the

required force is indicated. Release and remove the

torque wrench.

Repeat the application of a 2 pound force to the area

marked ªtest areaº. The safety cable should not touch the

wall of the verification fixture. Upon the successful

completion of this test, the tool can be used to apply

safety cable.