TM 1-1500-204-23-9

CHAPTER 8

TORQUE TOOLS AND TORQUE PRINCIPLES AND PROCEDURES

8-1. General. This chapter discusses the various types

of torque tools available to the aircraft repairer.

8-2. Types of Torque Tools. The torque tools which

are used in the maintenance of Army aircraft is as

follows.

a. Manual Torque Tools. Threaded fasteners can be

tightened by the following manual torque tool.

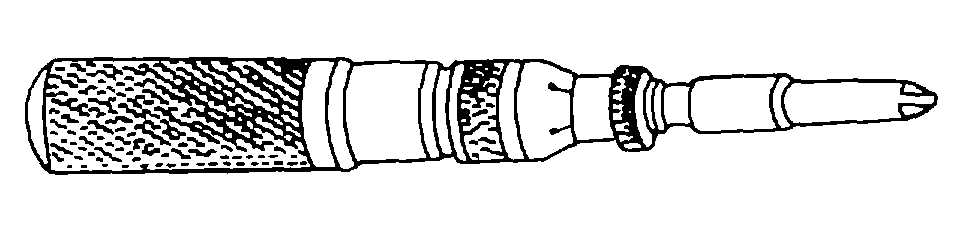

(1) Torque screwdriver. The preset screwdriver,

shown in figure 8-1, is preset to the desired torque. A

device in the tool limits the applied torque to the preset

torque by allowing the handle to turn free of the driven

bit when the preset torque is reached.

(2) Torque Wrenches. Torque wrenches are

divided into three types: deflecting beam, rigid frame

and audible indicating.

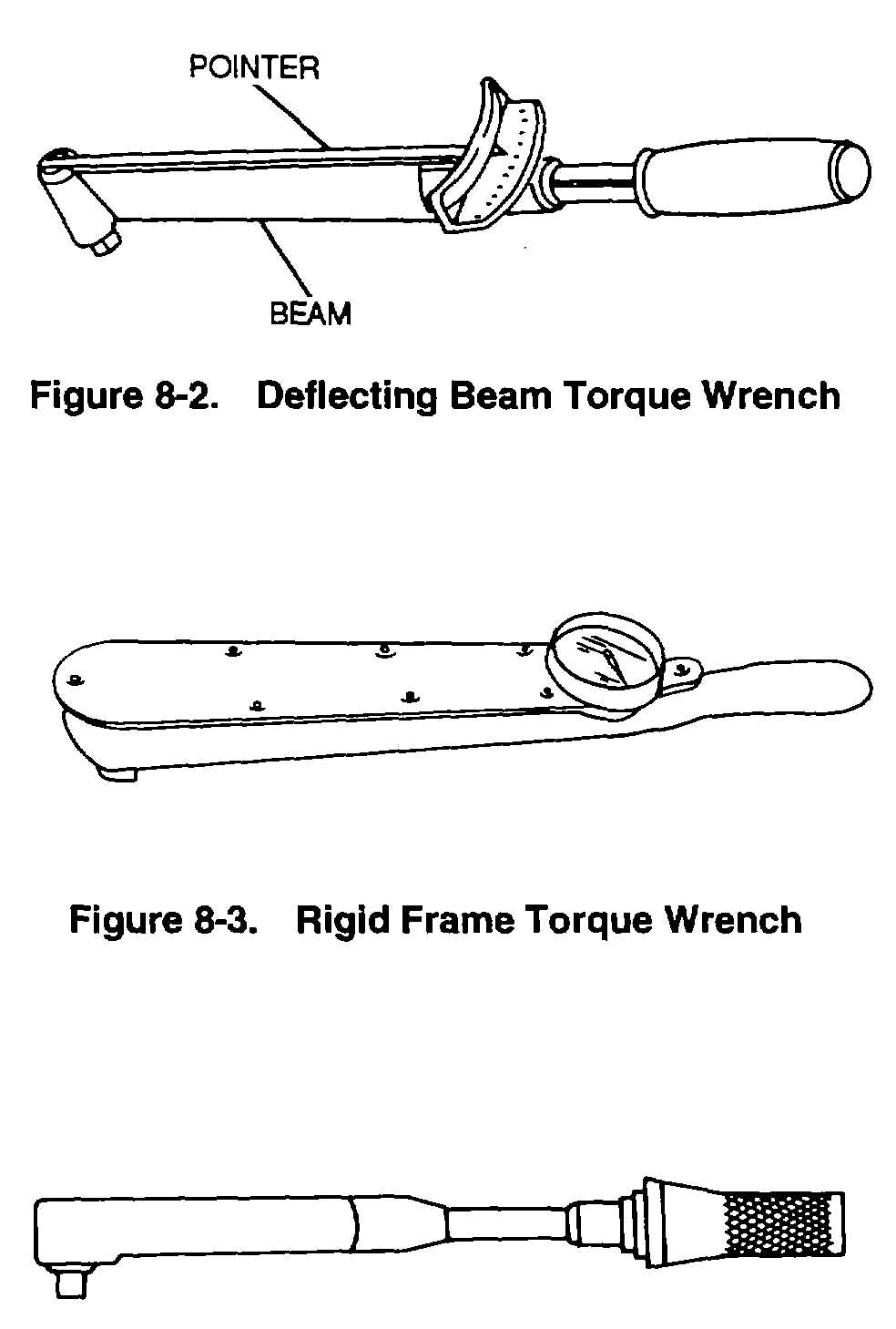

(a) Deflecting beam torque wrench. On the

deflecting beam torque wrench shown in figure 8-2, the

deflecting element is the beam itself. When a load is

applied, the beam bends (deflects). A pointer attached

to the socket end remains straight and indicates the

applied load as torque on a graduated plate attached to

the handle end. Other wrenches of this type may have

a graduated dial instead of the indicator plate. Audible

sensory indicators are sometimes provided in addition to

the indicator plate or dial. On the deflecting beam

wrench, the location of the grip on the handle determine

the length of the lever, and the accuracy of the torque

reading. For this reason, some flexible beam wrenches

are provided with a pivoted grip to insure that the point

of load application is maintained at the proper distance

from the socket drive.

Figure 8-1. Preset Torque Screwdriver

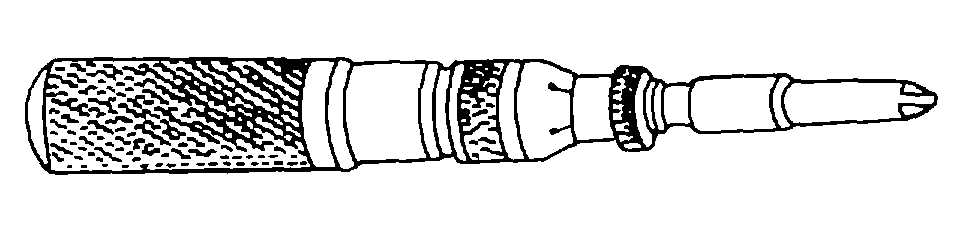

(b) Rigid frame torque wrench. The deflecting element

of the' rigid frame torque wrench shown in figure 8-3, is

enclosed in a rigid frame which functions as the lever.

The deflecting element actuates a needle on a

graduated dial that indicates the applied torque.

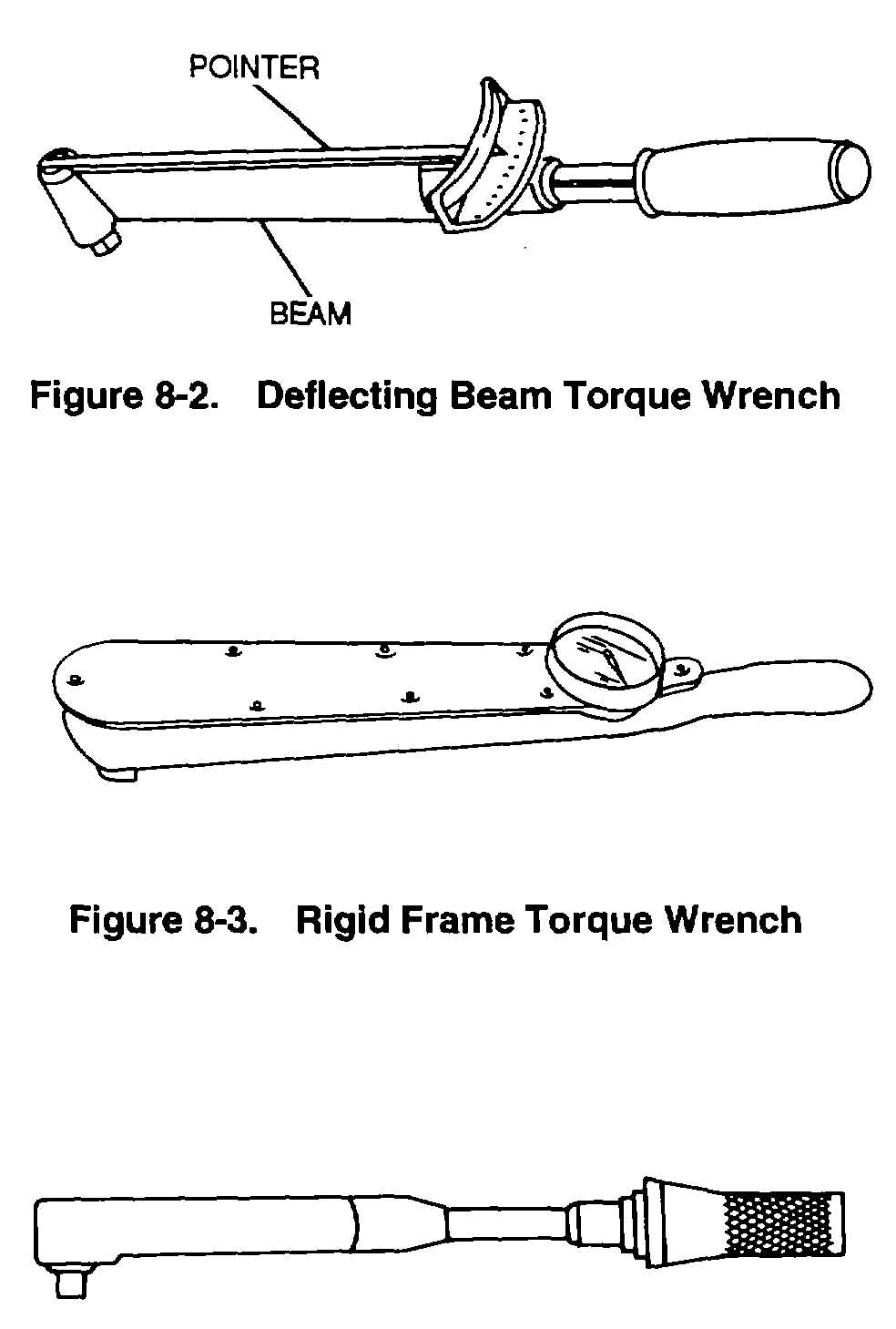

(c) Audible-indicating torque wrench. The audible-

indicating torque wrench, shown in figure 8-4, has a

micrometer-type barrel for presetting the desired torque.

The deflecting element is a compression spring that

applies pressure to a lever in a detent. When the preset

torque is reached, the lever slips out of the detent with

an audible click which can also be felt in the handle.

b. Power Torque Tools. The two common types of

powered torque tools are the nutrunner and screwdriver.

Figure 8-4. Audible-Indicating Torque Wrench

8-1

Figure 8-3. Rigid Frame Torque Wrench

Figure 8-2. Deflecting Beam Torque Wrench