TM 1-1500-204-23-9

and the impact wrench. These tools operate on

compressed air at a pressure of 90 (+10) psi. The air

supply hose must be a minimum 5/16 inch inside

diameter and should not be more than 15 feet long.

Observe all standard precautions for the use of air-

powered tools.

NOTE

The torque that the tool will apply to a

fastener at a given torsion bar setting is

dependent to some extent on the bolt

diameter and length, the type of nut,

and the compression characteristics of

the metal in the joint. The shutoff

torque of the tool must be checked and

the torsion bar adjusted as required

when there is any change in any of

these conditions, even though the

required torque remains the same.

8-3. Torque Wrench Selection. The appropriate

torque wrench can be selected for a specific job, based

on the type desired, the range of the tool, and the

appropriate torque units.

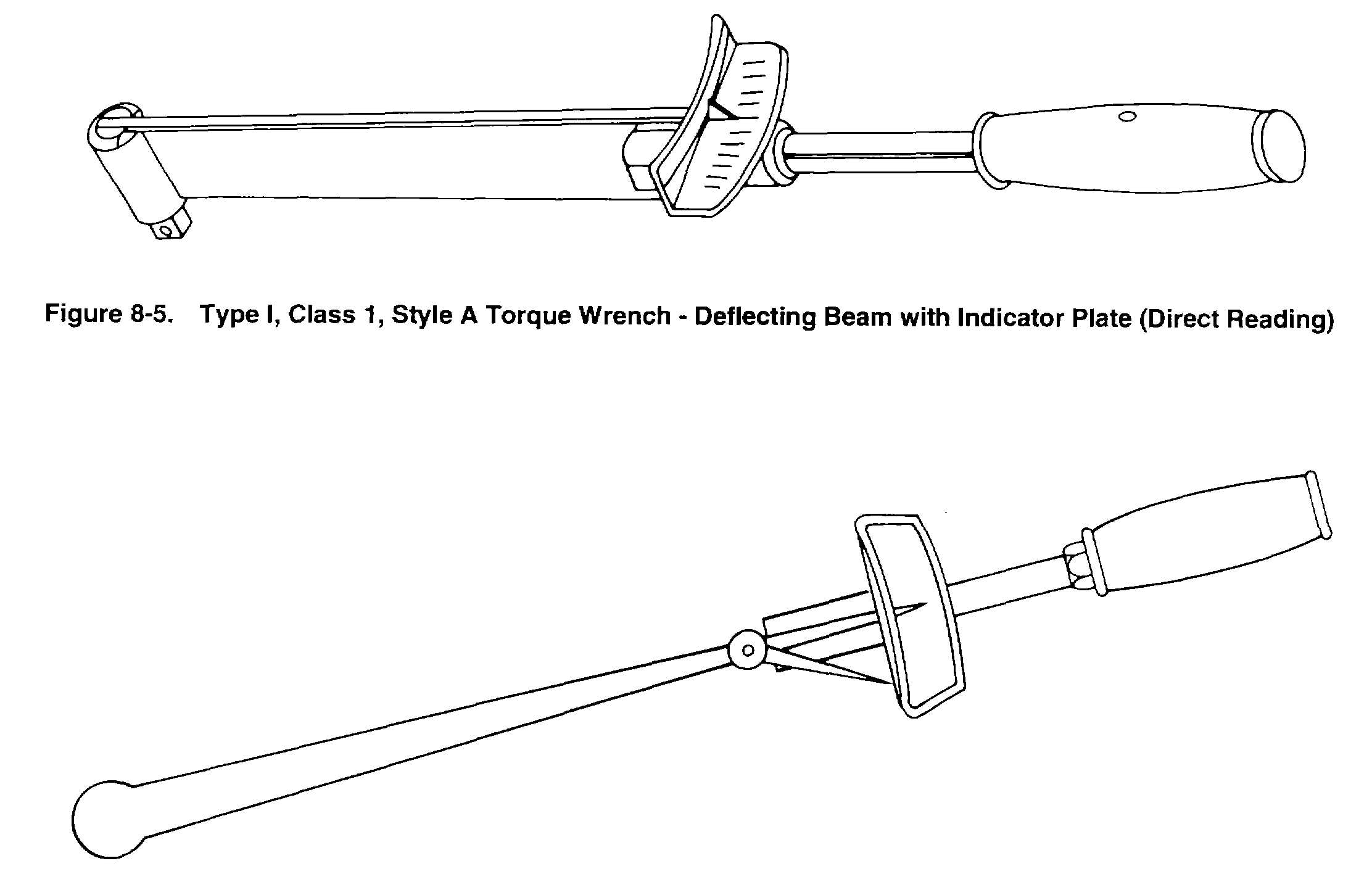

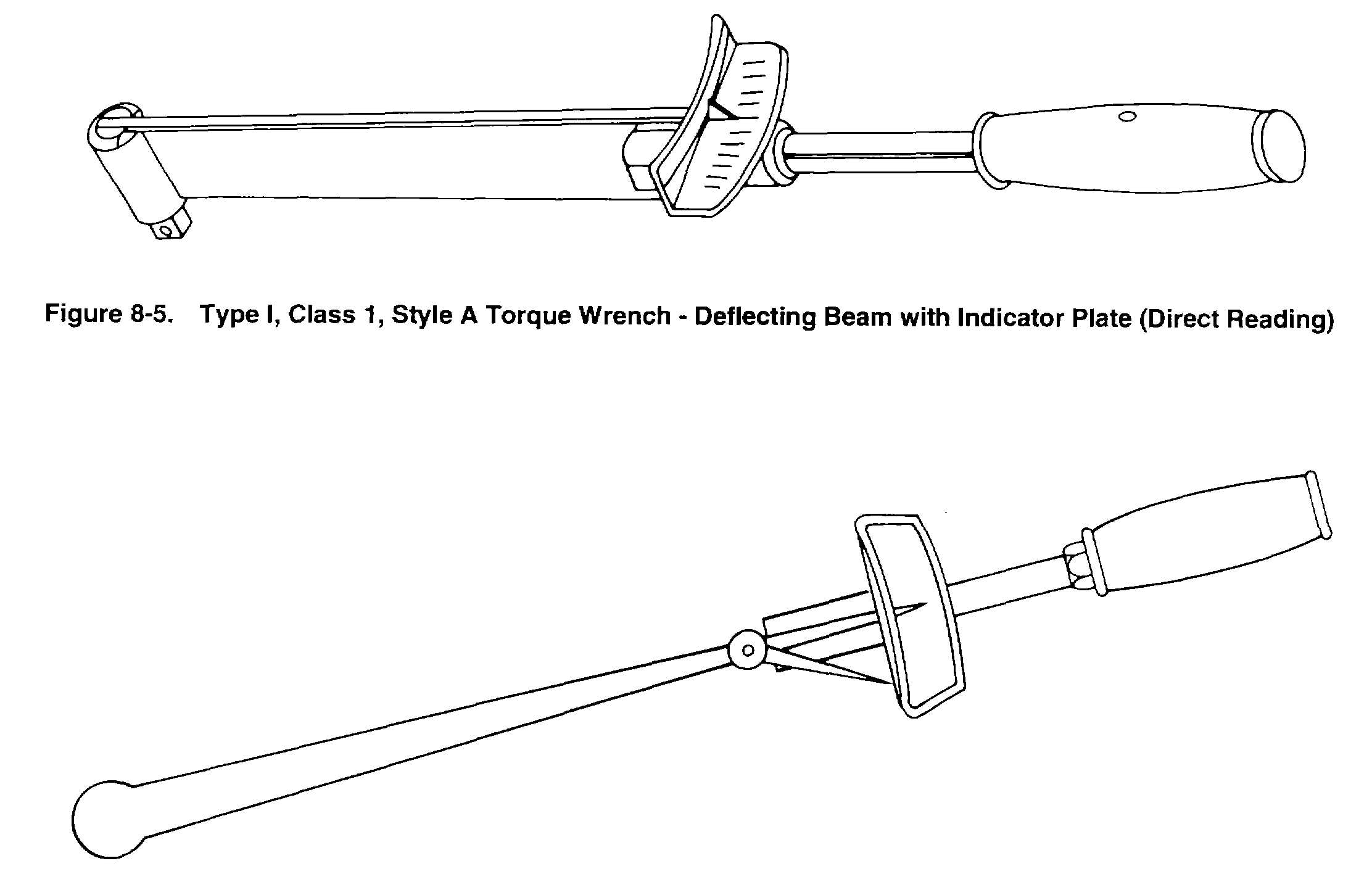

a. Types. In aircraft maintenance applications, the

rigid frame with the indicating dial and the audible

indicating torque wrenches are used in preference to the

flexible beam-type wrench. The audible-indicating

torque wrench is preferred since it can be used in places

of limited accessibility where it would be difficult to read

a dial or scale while performing the tightening operation.

For the combinations of features available in torque

wrenches, see figures 8-5 through 8-14.

b. Range. When selecting a torque for a particular

application,

the

range

of

the

wrench

must

be

considered. When practical, the required torque value

should be between the 30- and 80-percent points of the

torque wrench range. The accuracy of most torque

Figure 8-6. Type I, Class 1, Style B Torque Wrench - Deflecting Beam with Indicator Plate

(Direct Reading with Feel Impulse and Audible Signal)

Figure 8-5. Type I, Class 1, Style A Torque Wrench - Deflecting Beam with Indicator Plate (Direct Reading)

8-2