TM 1-1500-204-23-9

7-12 Change 4

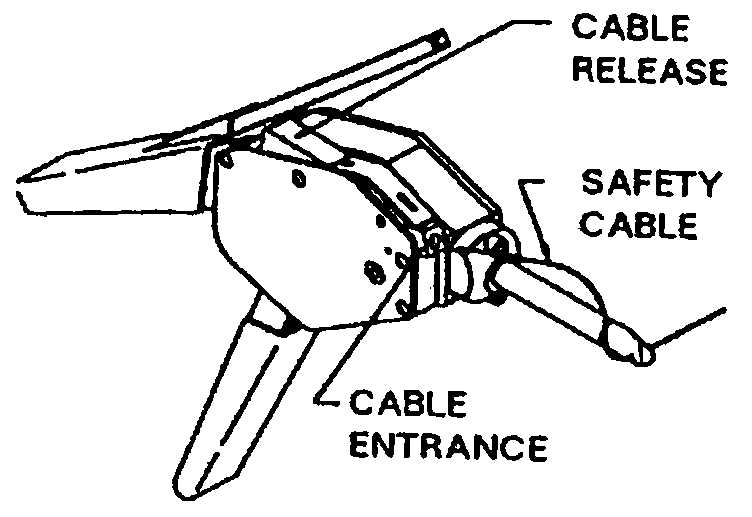

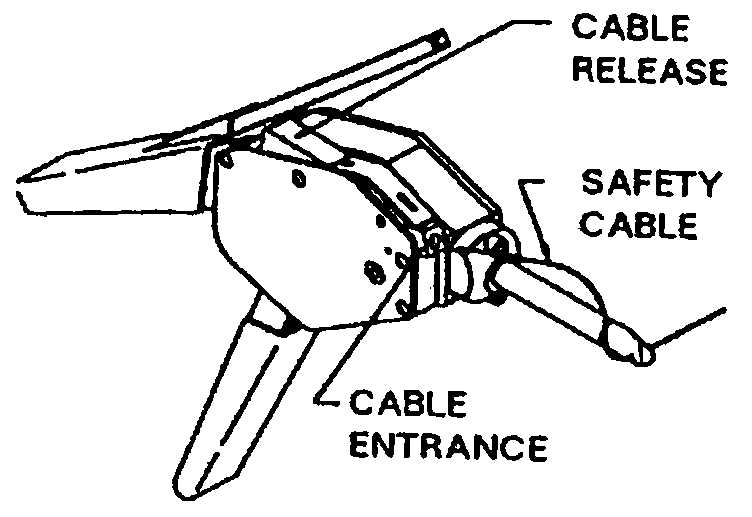

7-17. Safety Cable Application Tools.

a.

Pre-Set Tension Tool. (Figure 7-23.) Insert the

free end of the cable into the cable entrance and continue

to push the cable into the cavity. When the free end of the

cable appears at the bottom of the tool, grip the cable and

pull the slack from the cable by repeatedly closing the

tool handle allowing the handle to open fully before clos-

ing again. When all slack is removed from the cable, snug

the tool against the fastener by using several short

strokes of the handle. Release the handle to the full open

position and fully close the handle to crimp securely and

cut flush.

NOTE

It is important on this final stroke to

hold the tool as steady and perpen-

dicular to the cable as possible while

completing a full stroke. This

assures consistent tensioning of the

cable.

Figure 7-23. Pre-Set Tension Safety

Cable Application Tool

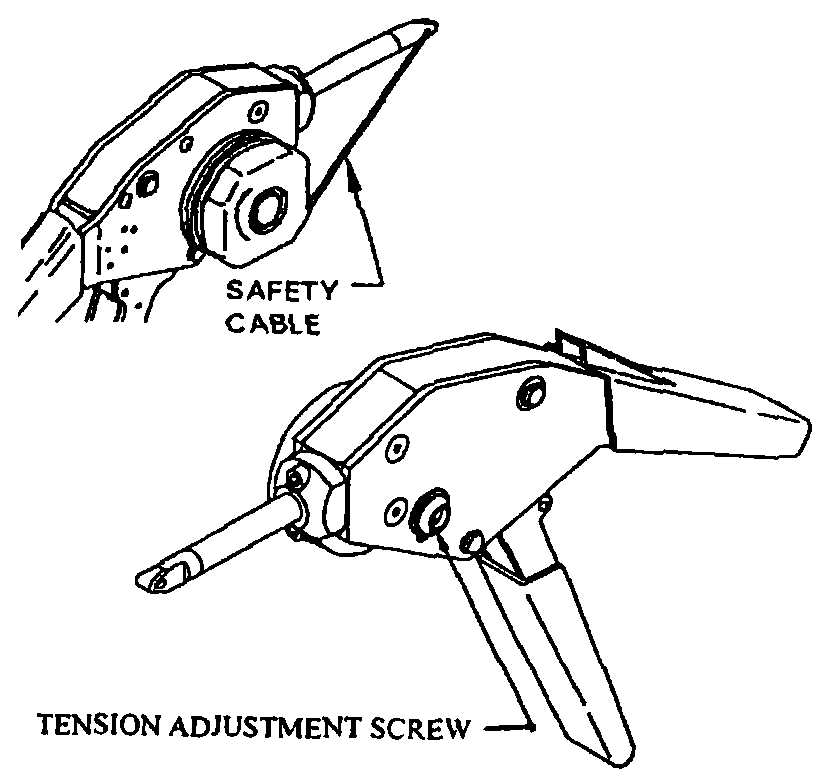

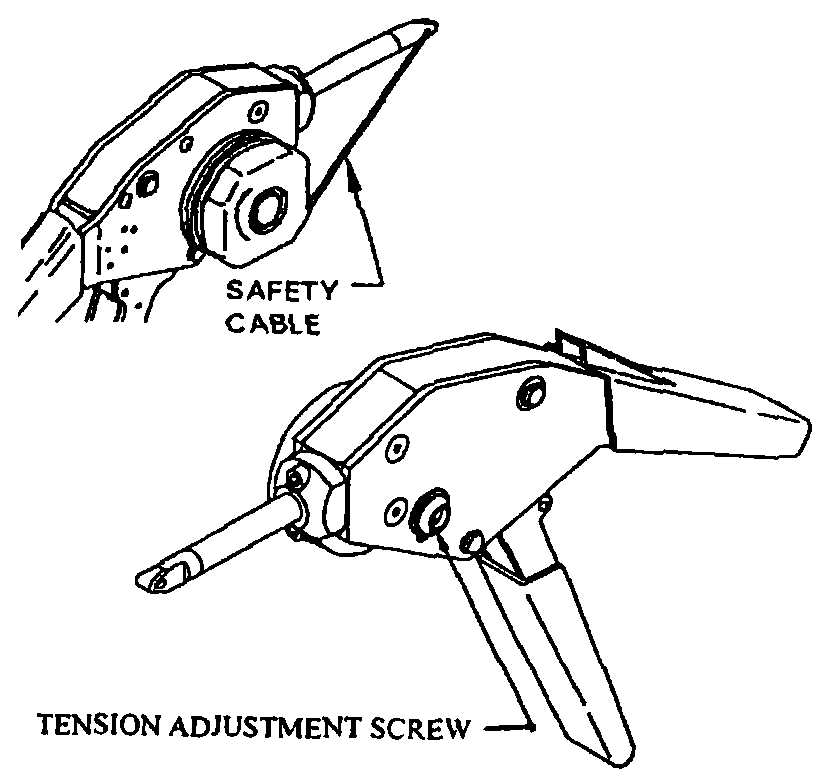

b.

Adjustable Tension Tool. (Figure 7-24.)

Thread the safety cable through the fastener, ferrule, and

tool nose in the same way as with other models. Wrap the

cable one full revolution (clockwise) around the tension

wheel, and with slight pressure applied by pulling the

cable, secure the cable into the slot. Rotate the tension

knob until several clicks are heard and felt. If additional

tension is required, adjustment can be made with the

tension adjuster on the opposite side of the tool.

CAUTION

Do not over tighten safety cable. It is

a good practice to find a tension set-

ting, which removes the slack from the

cable, (in order to meet the flex limit

requirement) without overstressing

the safety cable components.

(1)

Completely close the handles to crimp and

cut the cable. Hold the tool steady and perpendicular to

the cable to maintain constant cable tension. Release the

handle and remove the tool from the crimped ferrule.

Remove the excess cable segment from the tool prior to

the next application. If it is more convenient to use the

adjustable tension tool with the tension wheel on the

opposite side, you may remove the retaining ring located

on the opposite side from the tension wheel, slide the

tension wheel assembly out of the tool body, reinsert it

from the opposite direction, and replace the retaining

ring. The tension wheel is now located on the opposite

side of the tool.

NOTE

When using a hand tool, the tool

handles are to remain fully open

during the cable entry process (in

both tool models).

Figure 7-24. Adjustable Tension Safety

Cable Tool