TM 1-1500-204-23-9

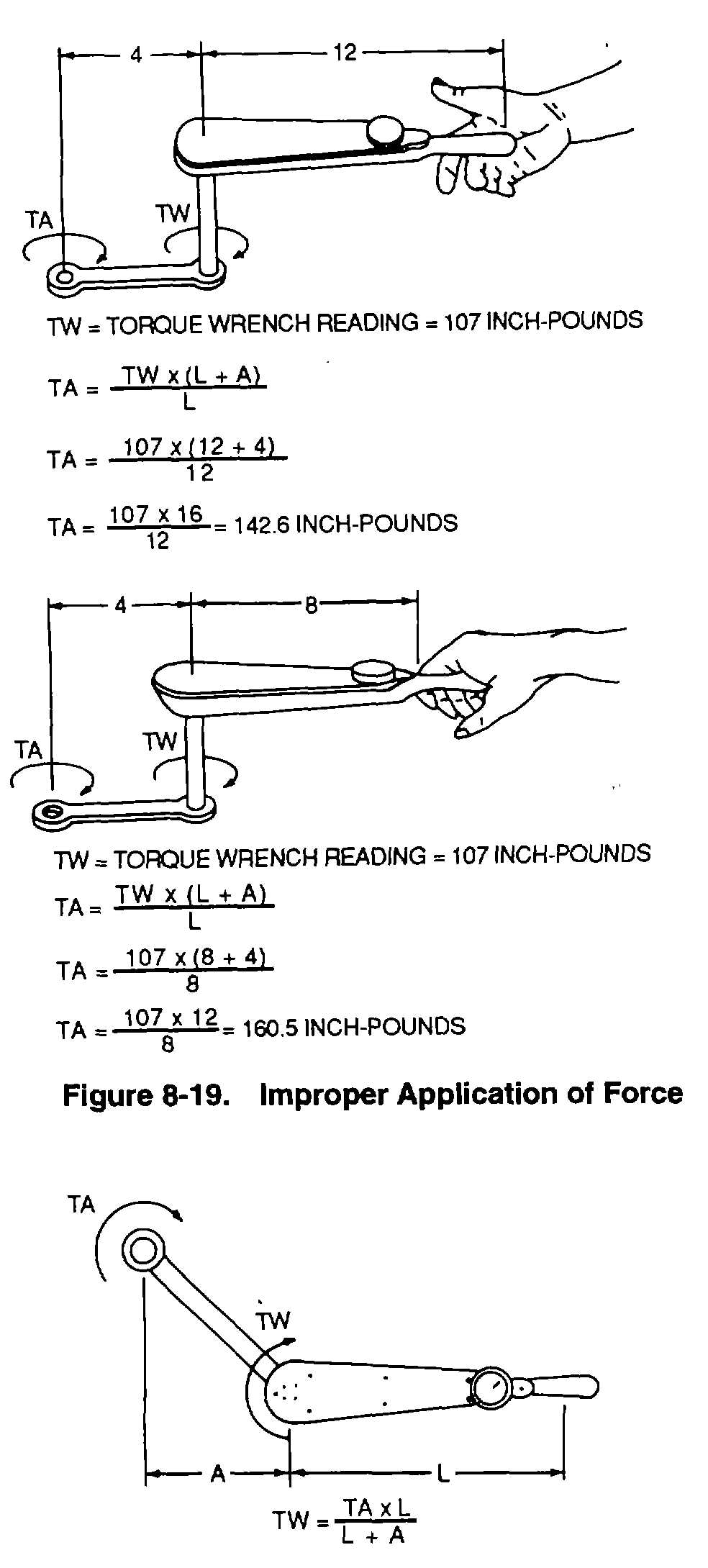

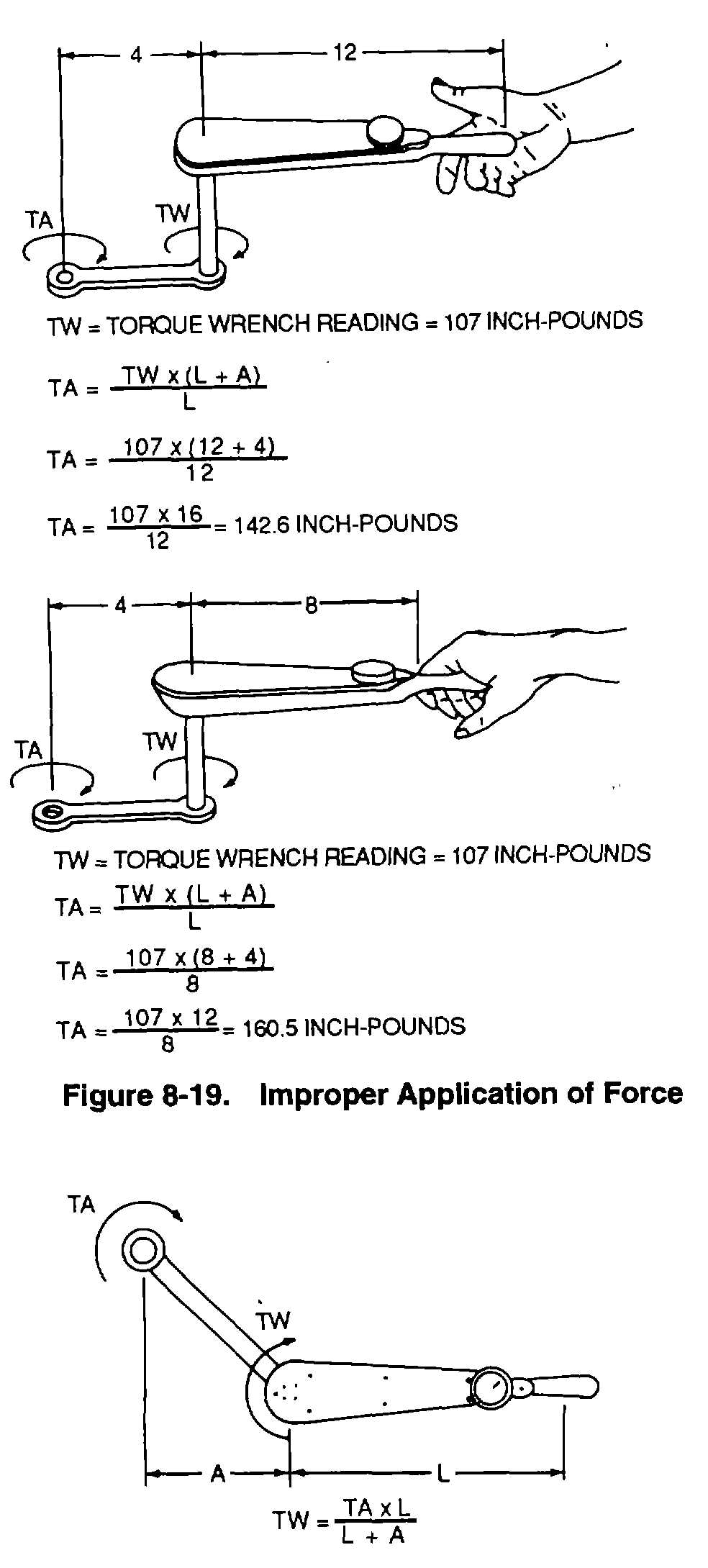

Figure 8-20. Angle Extension Torque

Wrench Attachment

c. Never drop a torque tool on the floor. If this does

happen, the wrench should be checked for accuracy

before its use.

d. Do not file, mark, or etch the beam of a flexible

beam wrench. This structure is the measuring element

of the wrench. Any alteration will seriously affect the

accuracy of the wrench.

e. Do not load a tool in excess of its capacity.

Overloading a torque tool can result in permanently

deforming the torque-sensing element and damaging

the tool.

f. Before use, check all nonadjusting torque wrenches

for minimum torque indication. If they do not indicate

minimum torque, tag them for calibration.

8-7. Testing of Torque Tools . A torque wrench is

subject to wear and other factors which can be

detrimental to the accuracy of the tool. Periodic testing

in accordance with applicable directives is essential to

ensure continued accuracy. Several different types of

torque wrench testers are manufactured and, to ensure

their proper use, some understanding of their operating

principles is desirable.

a. Description. A torque wrench tester consists of a

force resisting element to absorb the load applied by the

tool and a dial or scale to indicate the magnitude of the

applied load in torque units. A maximum reading

pointer is provided that remains at the point of

maximum applied torque and holds the reading when

the load is released until reset to zero by the operator.

b. Indication. The force resisting element may be a

weight, a steel spring, a torsion bar, or strain gauge load

cells. The movement of deflection of the force resisting

element resulting from the application of the load

applied by a torque wrench is relatively small and must

be magnified in order to indicate the small variations in

the amount of the applied load. Magnification is

accomplished on mechanical-type tester by a gear

segment and pinion or a mechanical linkage. Other

types

of testers use optical magnification or electronic

amplifiers.

8-8. Repair and Calibration. The repair and

calibration of torque tools is normally the responsibility

of the Area TMDE Support Team (ASTS) (TMDE is

Test, Measurement, and Diagnostic Equipment). TB

750-111 contains the procedures for repair and

calibration of torque wrenches for local units.

8-9. Torque Multipliers . The direct application of

torque to a fastener is limited by the force that can be

applied and by the length of the wrench. The force

varies to some extent but is approximately 100 pounds.

With a wrench 30 inches long, the torque that can be

applied is 100 x 30 or 3000 inch-pounds (250 foot-

pounds). Higher torque values are possible with longer

wrenches; however, there is a limit to the size of a

wrench that can be used effectively by one man.

Torque multipliers are used for the high torque values,

such as those specified

Figure 8-19. Improper Application of Force

8-9