TM 1-1500-204-23-9

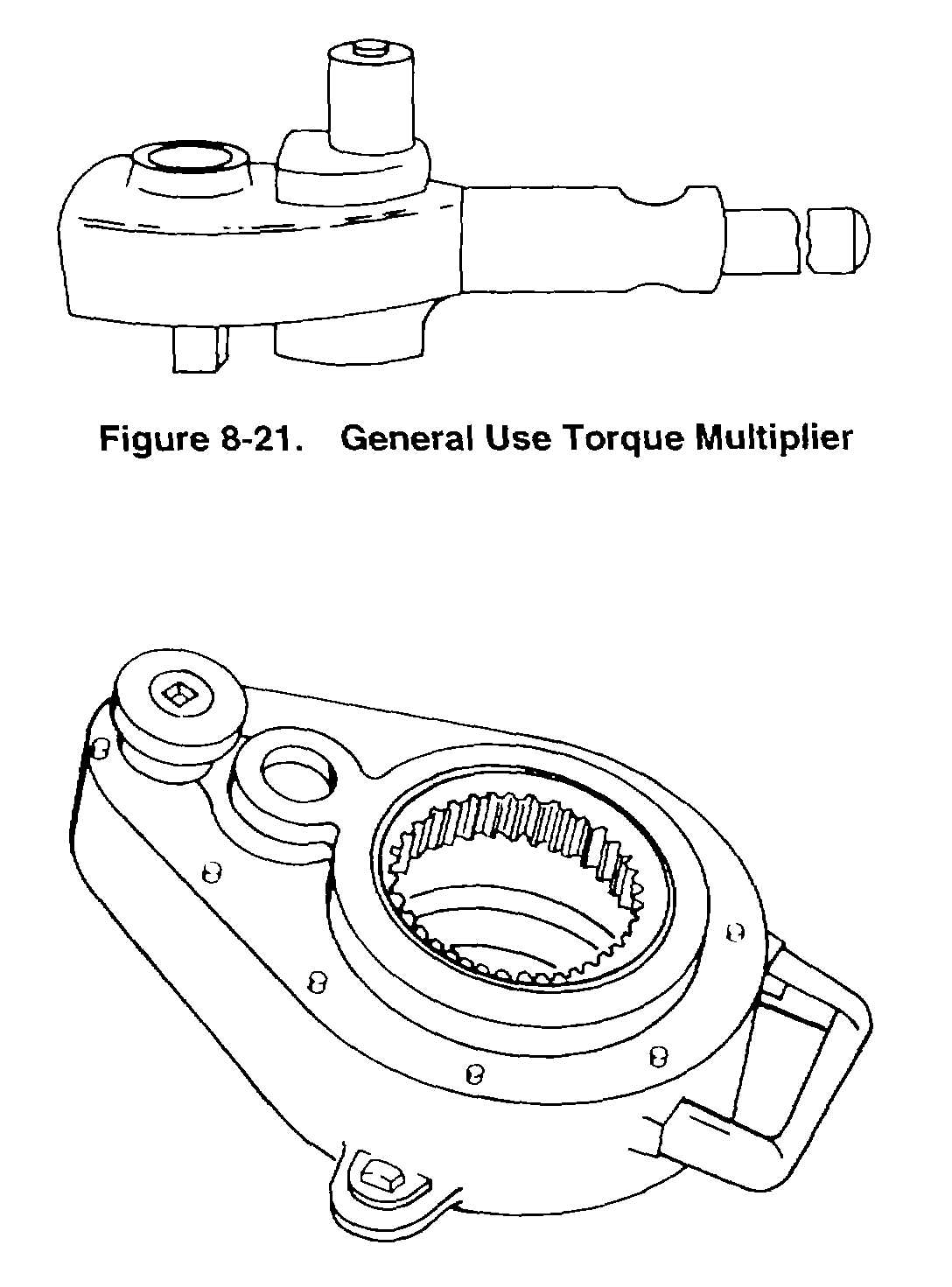

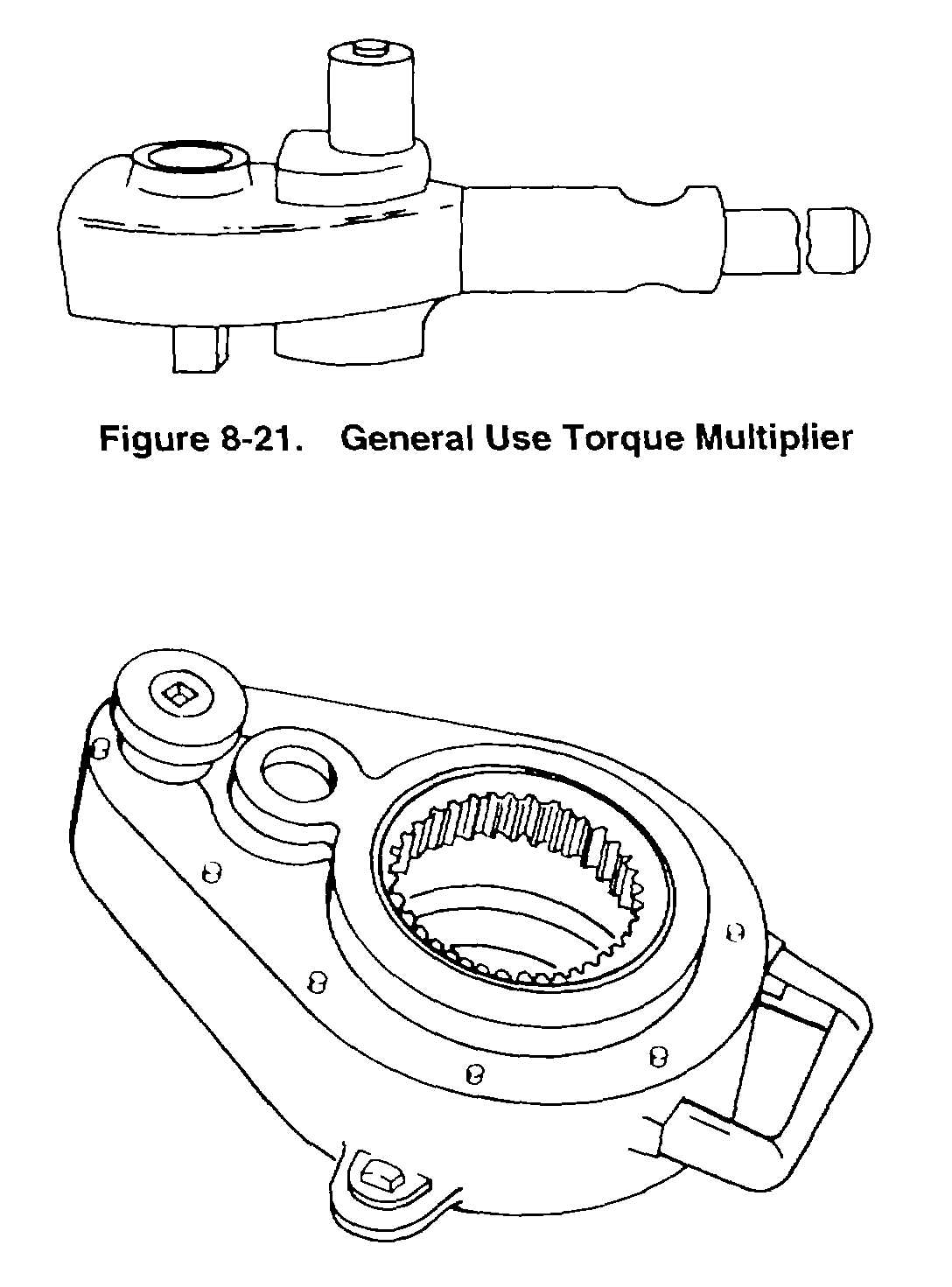

for engine thrust nuts, propeller nuts, and helicopter

rotor hub nuts. Figure 8-21 and 8-22 show typical

torque multipliers.

a. Use. Torque multipliers are available in ratios

ranging from 3:1 to 11.1:1. Multipliers must be

anchored or secured to a structure relative to the

fastener being tightened, or be fitted with a reaction bar

to prevent the multiplier from turning. For this reason,

their use is usually restricted to special applications.

b. Determining Torque. When using a torque

multiplier, the torque to be applied with the torque

wrench is determined by dividing the specified torque for

the fastener by the multiplier ratio. For example: If the

torque specified for the fastener is 3000 foot-pounds and

a torque multiplier with an 11.1 to 1 ratio is going to be

3000

used, then 11.1 or 270-pounds is the torque applied by

the torque wrench. In this case, a 350 foot-pound

capacity torque wrench or a wrench up to a 900 foot-

pound capacity would be used to apply 270 foot-pounds

of torque to the input of the torque multiplier. In this

range

Figure 8-22. Hub Nut Torque Multiplier

of torque wrenches, the applied torque is between the

desired 30- to 80-percent range.

8-10. Torque Multiplier Power Wrench. Utilizing a

powerful gear train, the torque multiplier power wrench,

shown in figure 8-23, is completely mechanical in its

operation. This tool operates on the same principle as

the general purpose torque multipliers described in

paragraph 8-9. The wrench is operated by turning a

small hand crank, but power tools (including air or

electric drills, nut runners, etc.), may be used for

speedier operation. A balanced features of the drive

gearing prevents snap-back should the input crank be

released.

a. Description. Output torque of the torque multiplier

power wrench, can be read directly. The torque

indicator is calibrated in foot-pounds or inch-pounds.

The operator can also read degree-of-turn on a

protractor on the input face of the unit. Wrench output

is a standard size square female drive. A ratchet

assembly controls the direction of rotation and provides

for quick take up and alignment. Counter torque is

absorbed by two pins located on the back of the wrench.

This reaction force is transferred to the load cells and

then to the gauge for direct output torque reading.

b. Use. As a general rule, always turn the input

handle in the direction that the output drive must turn.

Refer to the applicable aircraft maintenance manual for

specific uses for this tool.

NOTE

Do not use impact wrenches of any kind

to operate this wrench.

8-11. Torque Procedures Without a Torque Wrench.

In certain instances, when a torque wrench is not

available,

the

aircraft

maintenance

manual

may

prescribe an alternate method for determining that a

fastener is properly torqued. The two methods which

are commonly used are the wrench-arc method of

tightening, and the use of preload-indicating washers.

a. Wrench-Arc Method of Tightening. The wrench-arc

method of tightening will be used only when specified in

applicable aircraft maintenance manuals.

(1) Preliminary steps. The following paragraphs

provide preliminary steps that must be accomplished

before performing this operation:

Figure 8-21. General Use Torque Multiplier

8-10