TM 1-1500-204-23-9

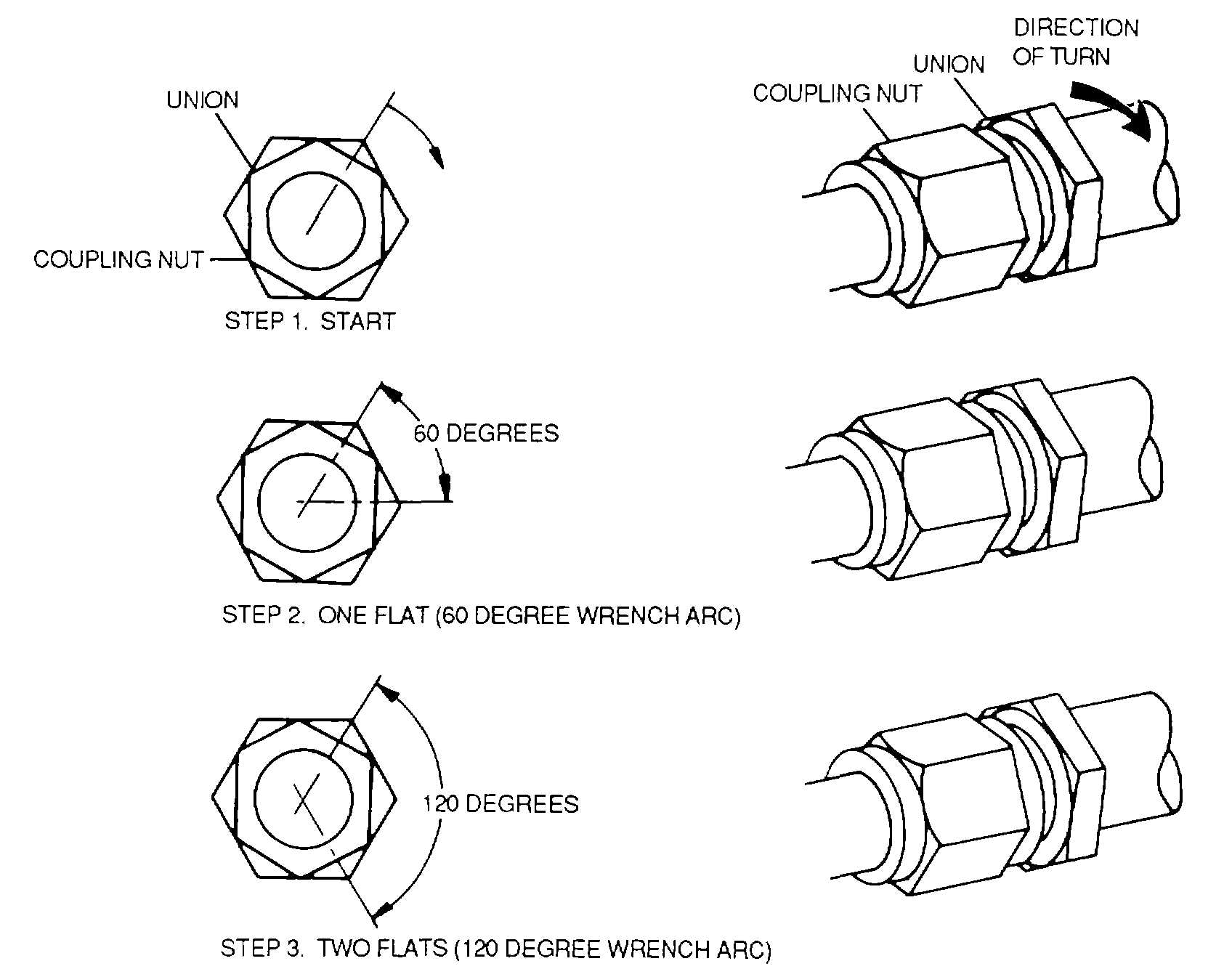

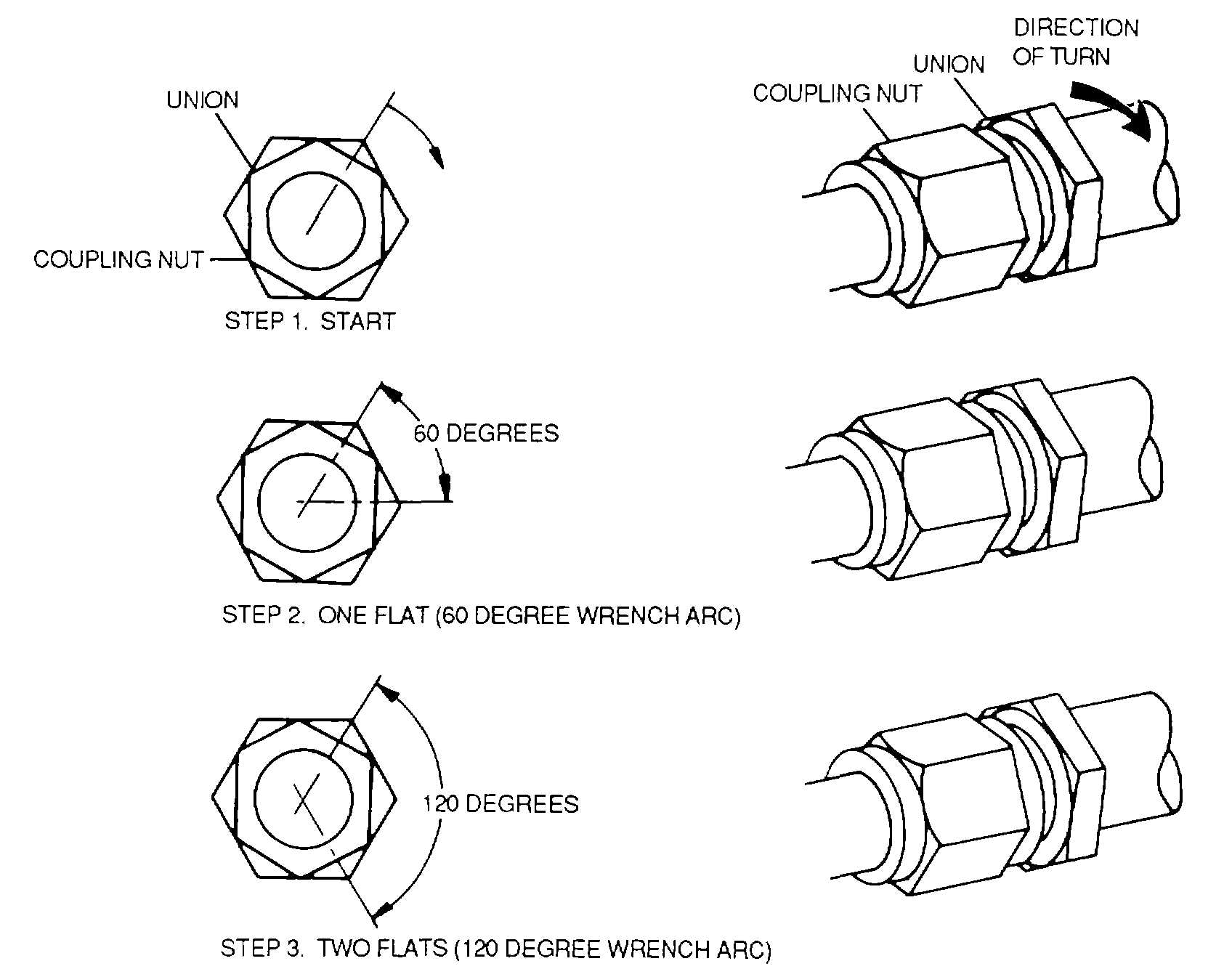

Figure 8-26. Tightening to 60- or 120-Degree Wrench Arc

(c) For 180 degree arc, turn wrench until handle

points in opposite direction.

b. Preload indicating Washers. The preload

indicating washer, shown in figure 8-29, consists of two

plain washers, one inner preload washer, and one outer

preload washer. The plain washers mash the inner

preload ring into the outer preload ring. When this has

occurred, the nut or bolt is properly tightened (see figure

8-30).

(1) Installation of preload washer on stud. To install

preload washers on a stud, see figure 8-31 and proceed

as follows:

(a) Install plain washer.

(b) Install inner preload washer.

(c) Install outer preload washer.

(d) Install plain washer.

(2) Installation of preload washer on a bolt. To

install preload washers on a bolt, see figure 8-32.

(3) Tightening. To tighten preload washers on a

stud or a bolt, see figure 8-33 and proceed as follows:

NOTE

An aircraft inspector or supervisor may be

required to be present during tightening of

the preload indicating washers to verify

that the preload washer has been properly

tightened.

(a) Place a ratchet handle wrench with socket on

the nut.

(b) Place a scribe in one of the preload indicating

outer ring holes.

(c) Move the preload ring with the scribe and

tighten the nut. As soon as the preload washer can no

8-14