TM 1-1500-204-23-9

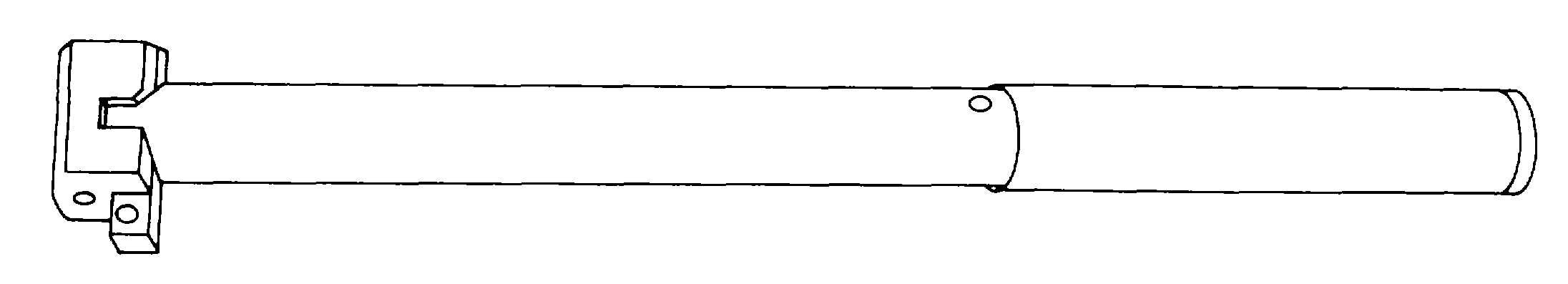

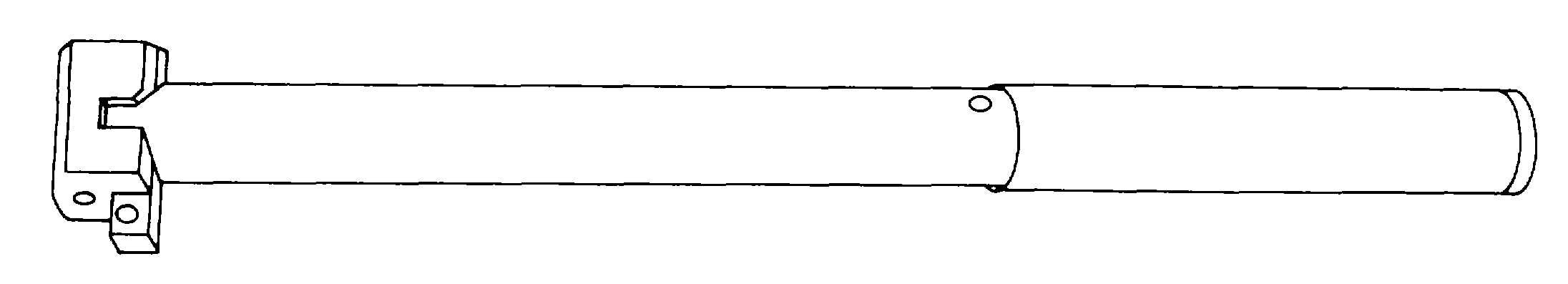

Figure 8-14. Type V Torque Wrench-Rigid Case, Preset Torque, Audible Signal

b. Reading the Torque Value. With the indicating

dial-type wrench, the torque value is read on the dial as

the force is applied. With the audible-indicating torque

wrench, the torque value is preset on the wrench by

releasing the lock in the end of the handle and rotating

the grip to the desired torque setting. When the preset

torque value is reached during the tightening operation,

the handle will automatically release or break, producing

approximately 15 to 20 degrees of free travel. This

release is distinct, easily detected by the mechanic, and

indicates completed torquing action on the fastener.

c. Use of Attachments and Extensions. Many torque

wrench applications will require the use of attachments

such as adapters and extensions to reach fasteners in

places of limited accessibility or to position the torque

wrench so that the dial is more easily read. In some

cases, the use of such attachments may greatly affect

the actual torque applied to the fastener.

(1) Concentric attachments. The use of an

attachment which operates in line with the drive square

of the wrench presents no particular problem, since the

effective length of the wrench is not lengthened or

shortened. The torque applied to the fastener will

therefore be the torque value indicated on the dial.

Figure 8-15 illustrates typical attachments of this type.

These attachments may also be used on the audible

indicating torque wrenches without affecting the torque

setting.

(2) Nonconcentric attachments.

For some

tightening applications, an attachment can be used on

the torque wrench that does not operate concentrically

with the drive square. An attachment of this type has

the effect of lengthening or shortening the lever length,

and the torque value shown on the dial is not the torque

that is applied to the fastener. When using these

attachments, it is necessary to calculate the effect of the

lever length to determine the correct torque reading.

Table 8-2. Recommended Torque Values

Fine Thread

Size

Plain &

Thin Plain &

and

Castellated Steel

Castellated Steel

Thread

Hex Nuts

Hex Nuts

Average

Average

8 - 36

12 - 15

7- 9

10- 32

20 -25

12 - 15

1/4 - 28

50 - 70

30 -40

5/16 - 24

100 - 140

60 - 85

3/8 - 24

160 - 190

95 - 110

7/16 - 20

450 - 500

270 -300

1/2 - 20

480 - 690

290 - 410

9/16 - 18

800 - 1000

480 - 600

5/8 - 18

1100 - 1300

600 - 780

3/4 - 16

2300 - 2500

1300 - 1500

7/8 - 14

2500 - 3000

1500 - 1800

1 - 14

3700 - 5500

2200 - 3300

11/8 - 12

5000 - 7000

3000 - 4200

11/4 - 12

9000 - 11000

5400 - 6000

Coarse Thread

8- 32

12 - 15

7- 9

10 -24

20 - 25

12 -15

1/4 - 20

40 - 50

25 - 30

5/16 - 18

80 - 90

48 - 55

3/8 - 16

160 - 185

95 - 100

7/16 - 14

235 -255

140 - 155

1/2 - 13

400 - 480

240 - 290

9/16 - 12

500 - 700

300 - 420

5/8 - 11

700 - 900

420 - 540

3/4 - 10

1150 - 1600

700 - 950

7/8 - 9

2200 - 3000

1300 - 1800

8-6