TM 1-1500-204-23-9

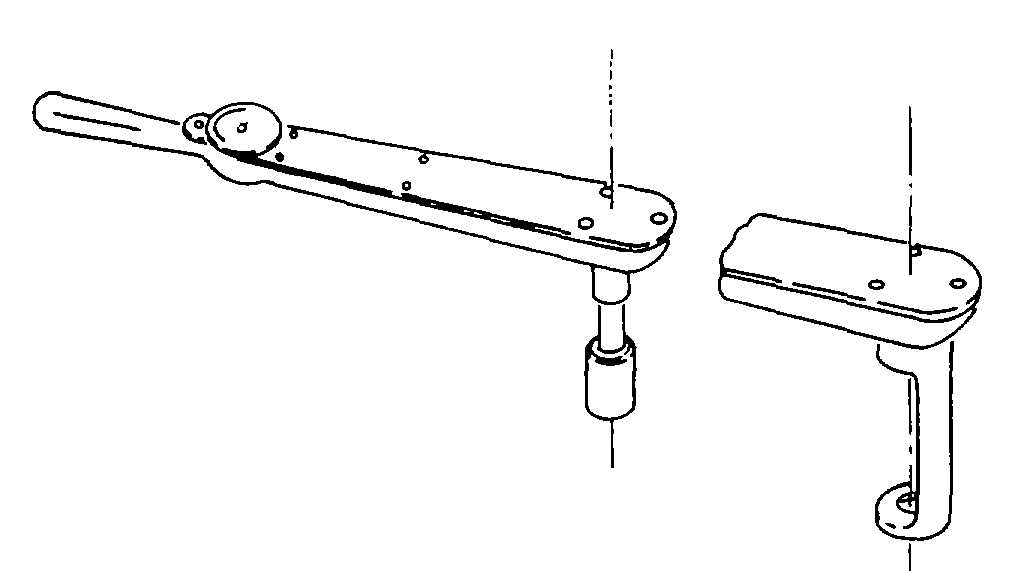

Figure 8-15. Concentric Torque Wrench

Attachments

(a) Extending lever length. Figure 8-16 shows an

attachment that adds to the lever length with the

applicable formula for obtaining the correct torque

reading. The formula is as follows:

TA x L

TW=

L+A

where:

TA = Actual torque applied to fastener

TW = Indicated torque value on torque wrench

L =

Lever length

A =

Attachment length

For example, if the length of the torque wrench is 10

inches, the length of the attachment Is 4 inches, and the

desired torque to be applied is 300 inch-pounds, the

formula would be completed as follows:

TA x L

TW=

L+A

300 x 10

TW=

10+4

3000

TW=

14

TW = 214 inch-pounds

Therefore, the torque wrench must indicate 214 inch-

pounds in order for the desired torque of 300 pounds to

be obtained on the fastener.

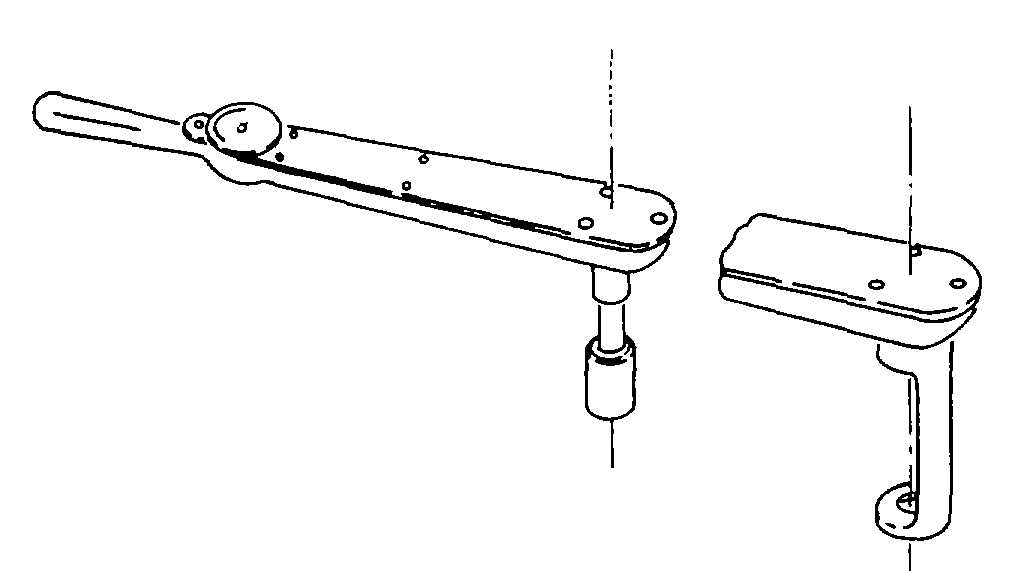

(b) Shortening lever length. In the previous case

of added lever length, the indicated torque value is

smaller than the actual torque value. Attachments,

when used as shown in figure 8-17, shorten the effective

lever length. In these instances, the attachment length

A is subtracted in the formula and the indicated torque

value is greater than the actual torque value.

(c) Importance of proper technique. When using

these formulas, the lever length L is a critical factor. On

a flexible beam-type wrench with a pivoted grip, this

dimension is fixed, and the pivot point of the grip

determines the point of force application and therefore

the length of the lever. On the rigid frame and audible-

indicating torque wrenches, the point of force application

must be in the center of the grip as shown in figure 8-18.

In figure 8-18, using the 10-inch lever length, 107 inch-

pounds of torque, as read on the torque wrench, results

in 150-pounds of torque on the fastener when the force

is applied correctly to the center of the grip. If the force

were applied to the torque wrench at the tip end or the

root of the grip, as shown in figure 8-19, at the same

107 inch-pounds reading, the torque applied to the

fastener would be 142.6 inch-pounds and 160.5 inch-

pounds, respectively.

(3) Angle attachments. Attachments will not always

extend straight from the end of the torque wrench. In

instances where the centerline of the adapter is not in

line with the centerline of the torque wrench, as shown

in figure 8-20, the length of the adapter is not used. The

effective length used to calculate the torque reading is

the distance A in figure 8-20.

8-6. Care of Torque Tools. A torque tool is a

precision measuring tool and, when handled and used

with

reasonable

care,

will

remain

accurate

and

serviceable for a considerable period of time. Observe

the following practices for the care and upkeep of torque

tools:

a. Never toss a torque tool carelessly among other

tools. Stow it in a clean, dry place where it will not be

subjected to shock or damage.

b. On audible-indicating torque wrenches, return the

micrometer-type barrel to lowest setting after each use

and before returning to storage.

Change 1

8-7