TM 1-1500-204-23-9

Table 3-2. Snap Gauge Tolerances

To and

Above

Including

X1

Y2

Z3

0.029

0.825

0.00004

0.00007

0.00010

0.825

1.510

0.00006

0.00009

0.00012

1.510

2.510

0.00008

0.00012

0.00016

2.510

4.510

0.00010

0.00015

0.00020

4.510

6.510

0.00013

0.00019

0.00025

6.510

9.010

0.00016

0.00024

0.00032

9.010

12.010

0.00020

0.00030

0.00040

1

Precision lapped

2

Lapped

3

Ground or polished (grinding marks may be in evidence)

(a)

Clamp the snap gauge in a vise

or a holder.

CAUTION

To prevent damage to the gauge from the

jaws of the vise, cover the jaws of the

vise with blocks of wood or sheets of soft

metal, such as brass.

NOTE

This procedure describes adjusting the

GO dimension first; however, either the

GO or the NO GO dimension may be

adjusted first.

(b)

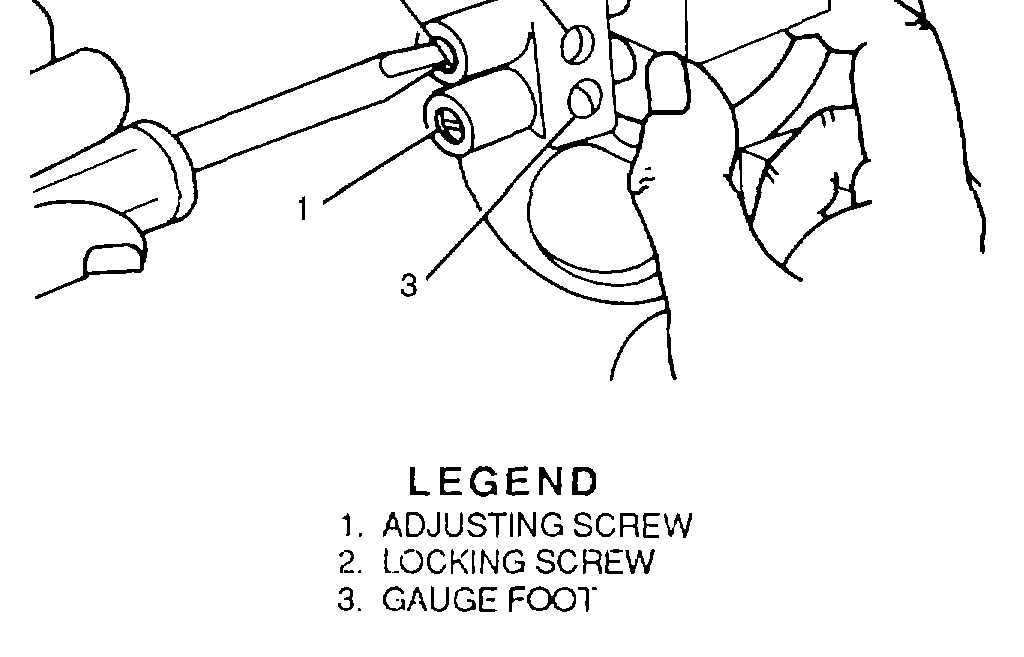

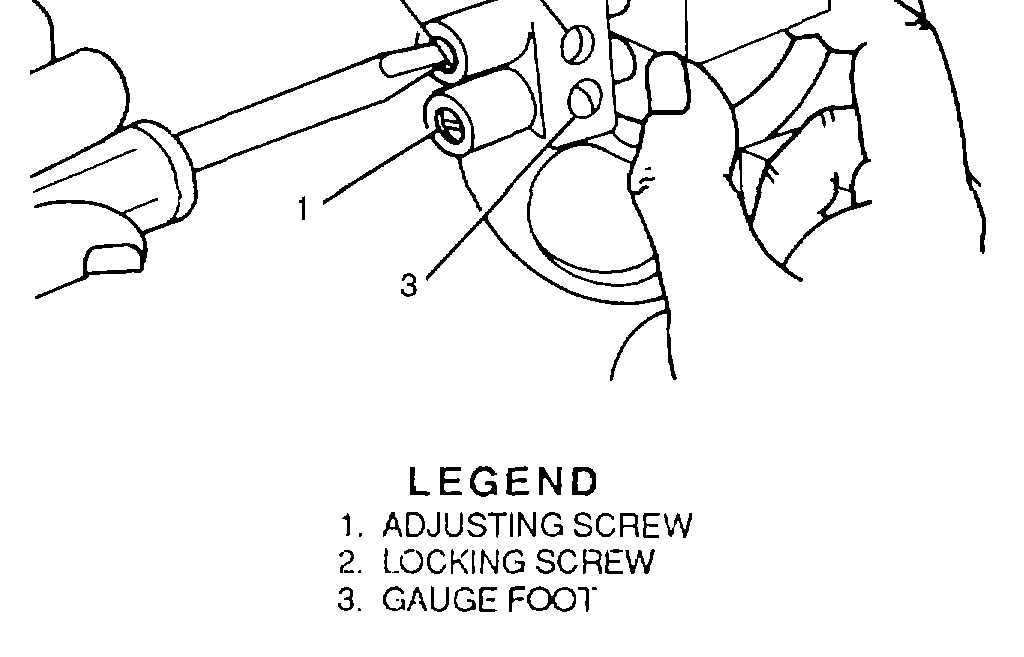

As shown in figure 3-65, turn

the locking screw (2) and turn the adjusting screws (1)

until the dimension is set (3).

NOTE

The desired dimension may be taken

from a master disc, a precision gauge

block, or a master plug.

(c)

Turn the other adjusting screw

until the NO GO dimension is set.

(d)

Tighten the locking screws with

the master precision piece still in place.

(e)

Remove the master precision

piece.

(f)

Recheck the gauge to make

sure the dimensions have not changed before using the

gauge.

LEGEND

1. ADJUSTING

2. LOCKINGSCREW

3. GAUGEFOOT

Figure 3-65. Adjusting the Snap Gauge

3-30