TM 1-1500-204-23-9

(a)

Find the slot that refuses to

pass the wire without forcing.

(b)

Try the next larger slots until

one is found that passes the wire. This is the correct

size.

NOTE

·

Measurements are taken at the slot portion

rather than the cutout portion of the gauge.

·

The decimal equivalent of the gauge

number is shown on the opposite side of the gauge.

c.

Care. Observe the following practices for

the care and upkeep of sheet metal and wire gauges:

(1)

Coat metal parts of wire gauges with a

light coat of oil to prevent rust.

(2)

Store gauges in separate containers.

(3)

Keep graduations and markings clean

and legible.

(4)

Do not drop wire gauges. Small nicks

and scratches will result in inaccurate measurements.

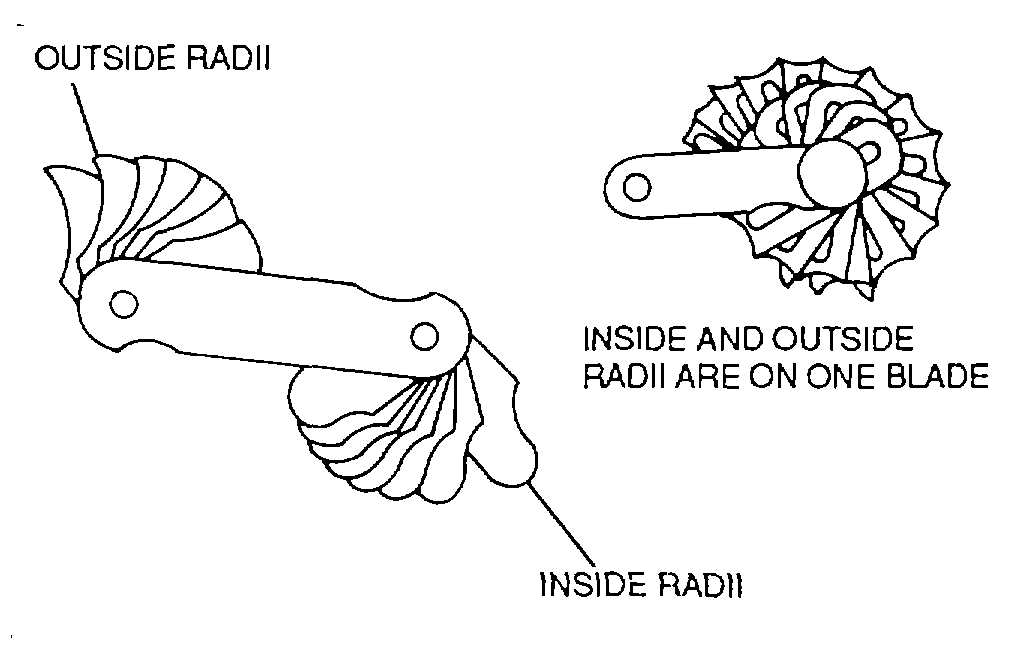

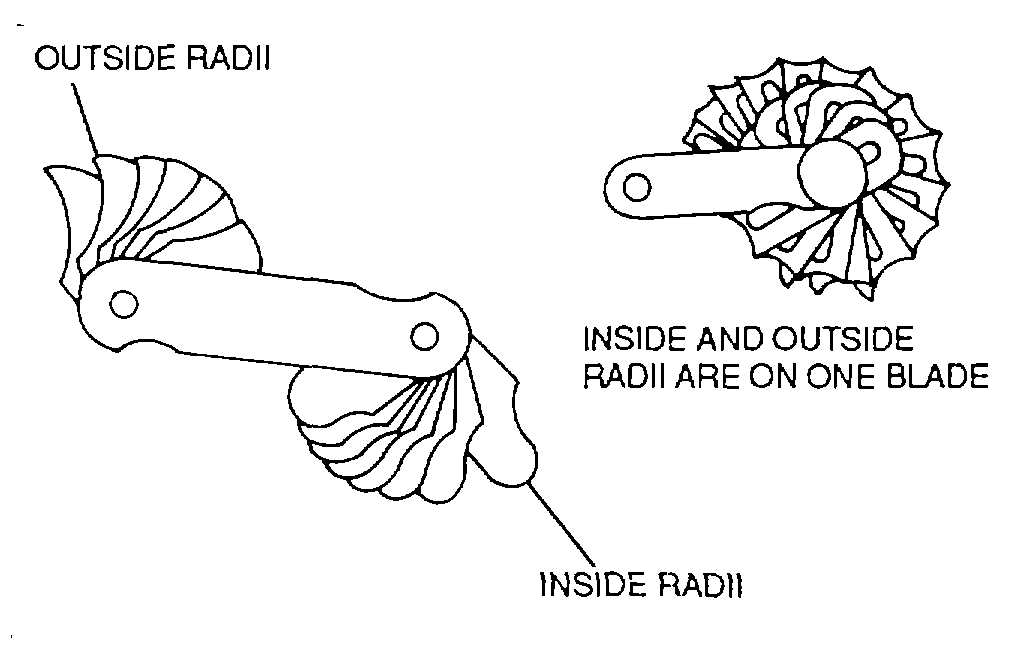

3-19. Fillet and Radius Gauges. Fillet and radius

gauges are used to check the inside or outside corners

(or fillets) of a machined part.

a.

Description. The blades of fillet and radius

gauges are made of hard-rolled steel. The double

ended blades of the gauge have a lock which holds the

blades in position. The inside and outside radii are on

one blade on one of the gauges shown in figure 3-73.

The other gauge has separate blades for inside and

outside measurements. Each blade of each gauge is

marked in 64ths. Each gauge has 16 blades.

b.

Use. Fillet or radius gauges are used to

check the inside or outside corners of a machined part,

as shown in figure 3-74. These gauges can be used in

any position and at any angle for both inside and outside

radii.

c.

Care. Observe the following practices for

the care and upkeep of fillet and radius gauges:

Figure 3-73. Fillet and Radius Gauges

(1)

Coat metal parts of fillet and radius

gauges with a light film of oil to prevent rust.

(2)

Store gauges in separate containers.

(3)

Keep graduations and markings clean

and legible.

(4)

Do not drop fillet and radius gauges.

Small nicks and scratches will result in inaccurate

measurements.

3-20. Dial Indicators. A dial indicator is a precision

measuring tool designed for checking items such as

bearing radial and axial play, propeller shaft run out,

bushing and flight control system components for

excessive play. The dial indicator plays an important

part in deciding if a part is worn beyond an allowable

tolerance.

a.

Description. The dial indicator consists of a

dial with reading needle and a graduated scale. The dial

indicator has a measuring range from 0.001 to 0.200 of

an inch. The dial is adjustable and has the reading

pointer located on the back of the dial. The indicator

can be mounted in various positions using a special

clamp and tool post holder which is provided in the dial

indicator kit. This assembly is shown in figure 3-75.

b.

Use. Generally speaking, the dial indicator

measures variations from a perfectly circular condition.

Proceed with installation and use as follows:

3-34