TM 1-1500-204-23-9

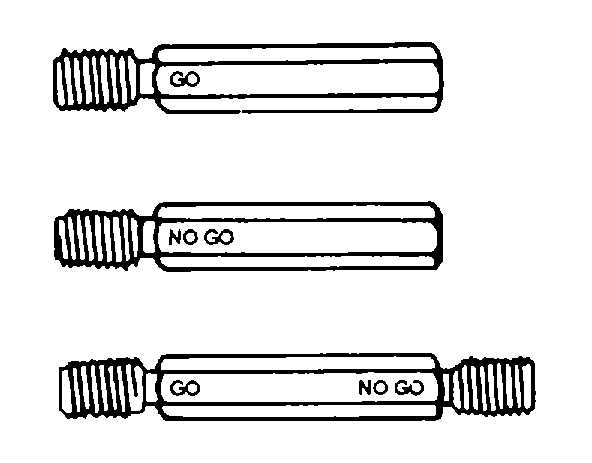

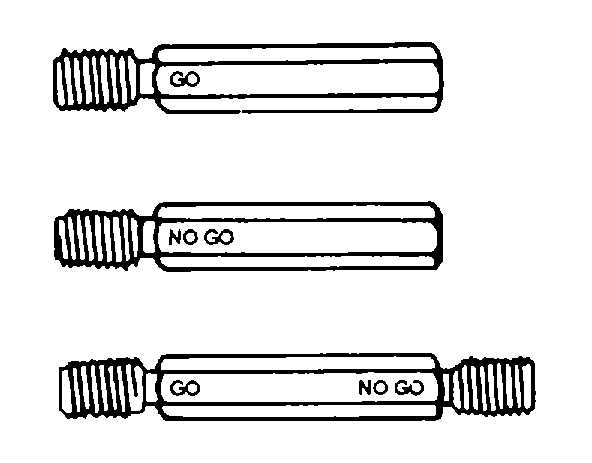

Figure 3-54. Plug Gauges

(2)

NO GO gauge. An internal thread within

limits must not accept the NO GO gauge past 1 1/2

turns.

b.

Care. Ensure that plug gauges are carefully

handled, as the threads are machined to within very fine

tolerances, and any damage will alter the accuracy of

the measurements. Observe the following additional

practices for the care and upkeep of plug gauges:

(1)

Coat metal parts with a light film of oil to

prevent rust.

(2)

Store gauges in separate containers

provided by the manufacturer.

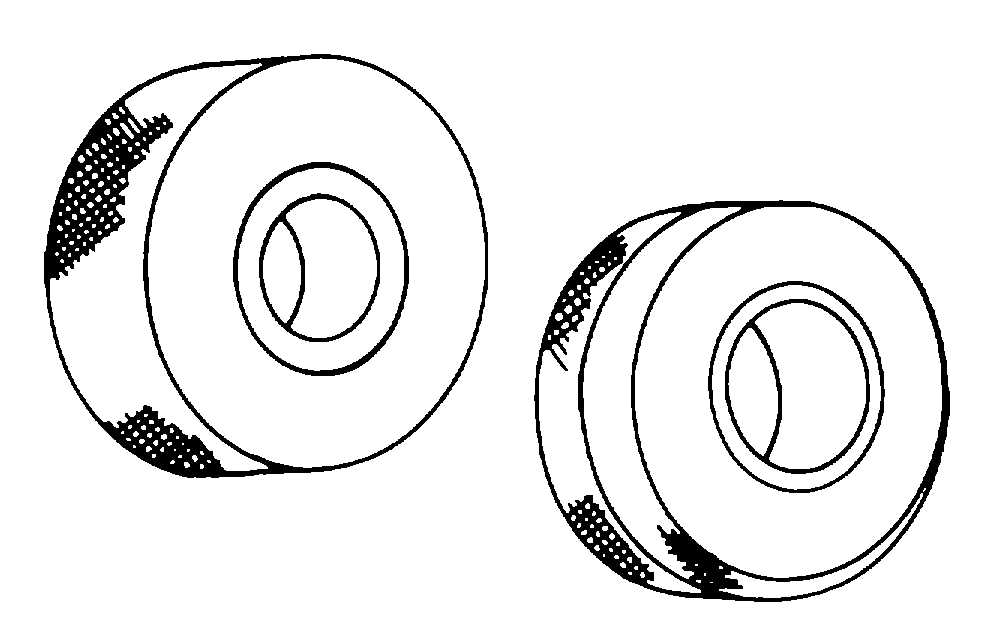

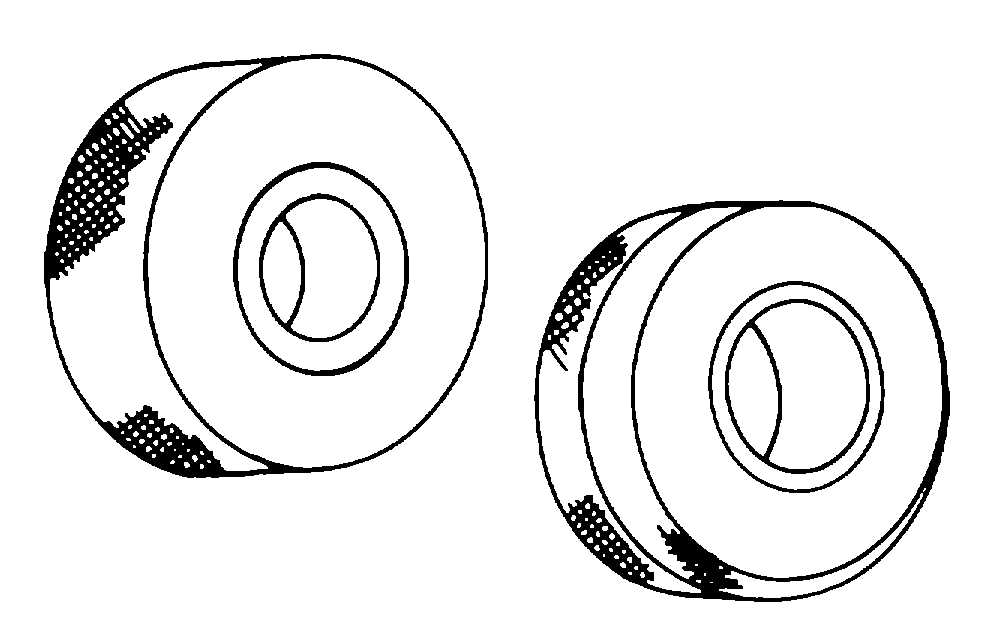

3-15. Ring Gauges. Ring gauges, shown in figure 3-

55, are used as standards to determine whether or not

one or more dimensions of a manufactured post are

within specified limits. They are nonadjustable, and

therefore called fixed gauges.

a.

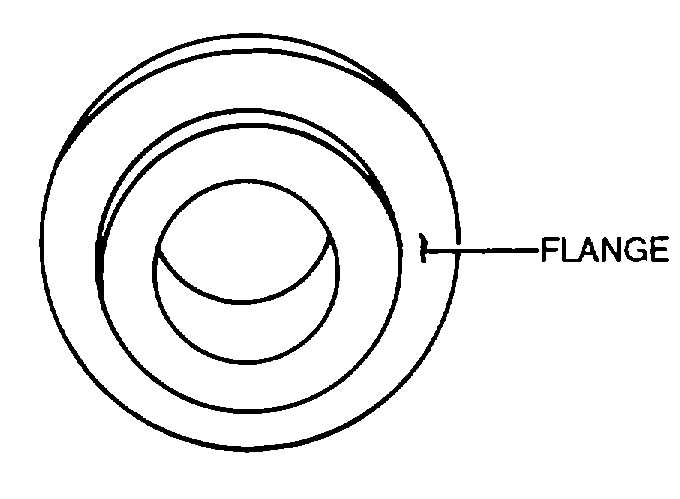

Description. The ring gauge is an external

gauge of circular form. For sizes between 0.059 and

0.510 inch, ring gauges are made with a hardened

bushing pressed into a soft body. The thickness of the

gauge ranges from 3/16 to 1 5/16 inches. Ring gauges

made for diameters of 0.510 to 1.510 inches are made

in one piece, without the hardened bushing. Gauges

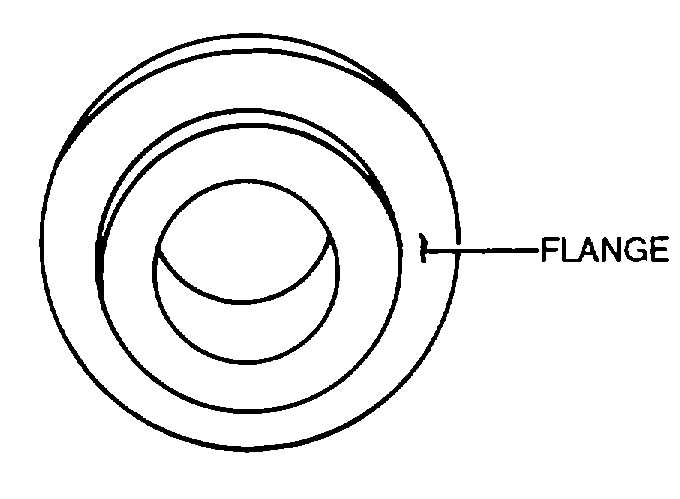

ranging in diameter from 1.510 to 5.510 inches are

made with a flange, as shown in figure 3-56, which

reduces the weight and makes them easier to handle.

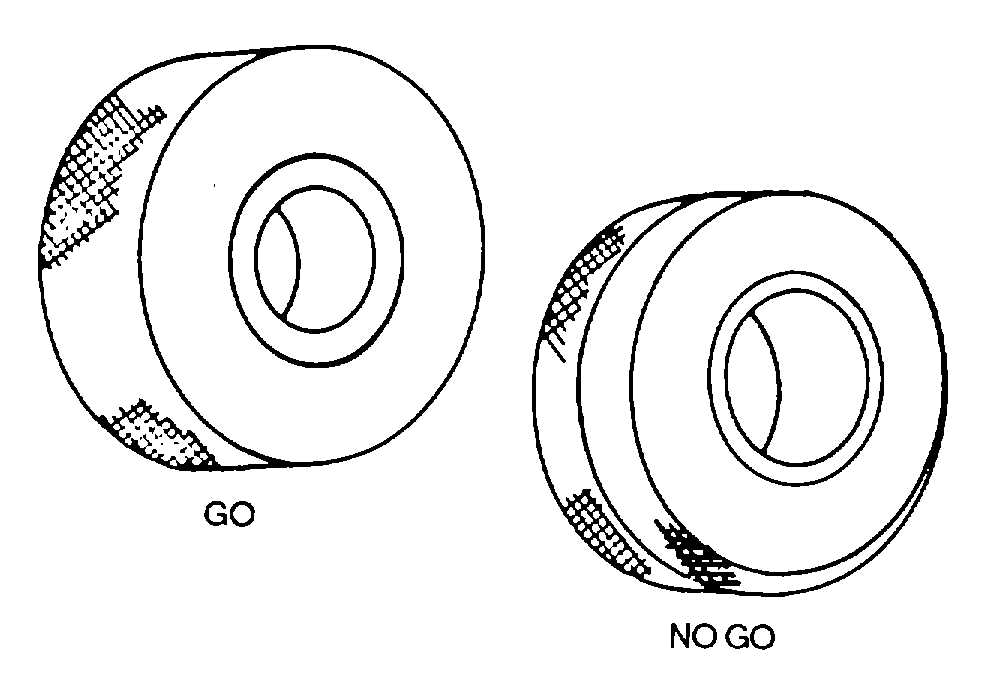

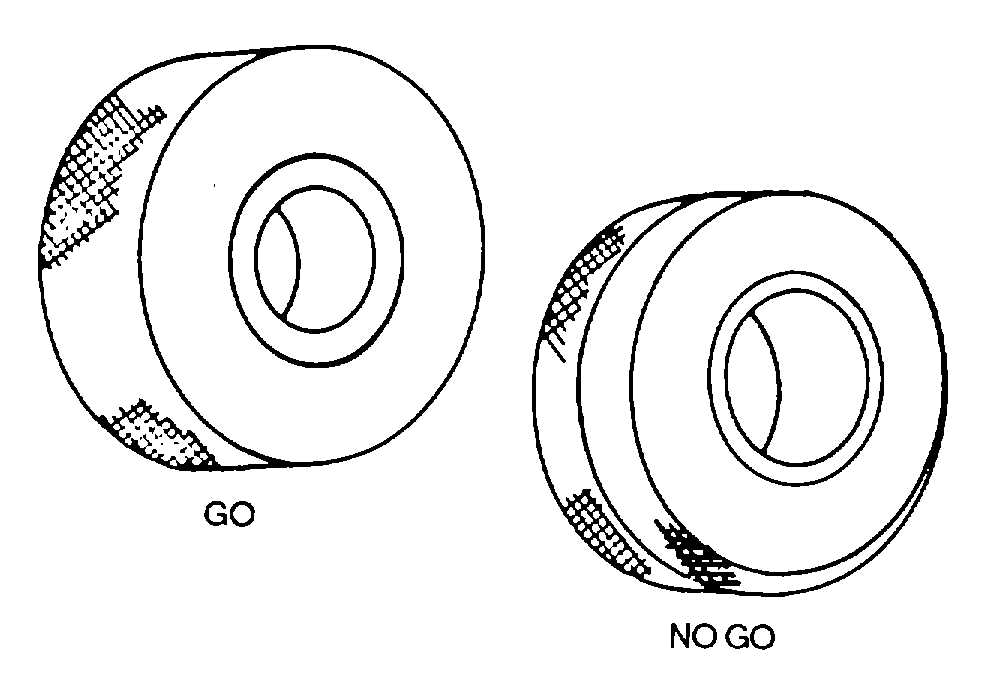

There are two types of ring gauges; the GO and the NO

GO gauges (see figure 3-57).

(1)

GO ring gauges. GO ring gauges are

larger than NO GO gauges. The outer surface of the

ring is knurled.

Figure 3-55. Ring Gauges

Figure 3-56. Flanged Ring Gauge

Figure 3-57. Ring Gauge Types

3-25