TM 1-1500-204-23-9

a.

Operation. Height gauges usually have vernier

scales, and are operated similarly to depth gauges, as

outlined in paragraph 3-11b(2). The clamping screws

ensure that the measuring arm will not slip after the

gauge is removed from the object being measured.

b.

Care. Observe the following practices for the

care and upkeep of height gauges:

(1)

Coat all metal parts of height gauges with

a light coat of oil to prevent rust.

(2)

Carefully store height gauges in separate

containers provided by manufacturer.

(3)

Keep graduations and markings clean and

legible.

(4)

Do not drop any height gauge. Small

nicks

and

scratches

can

cause

inaccurate

measurements.

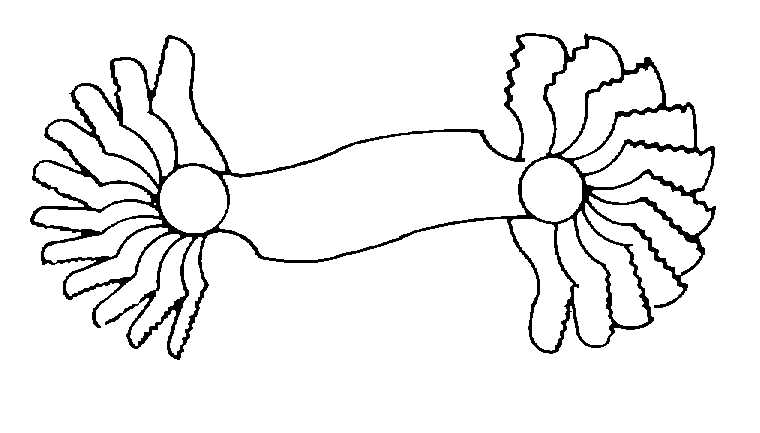

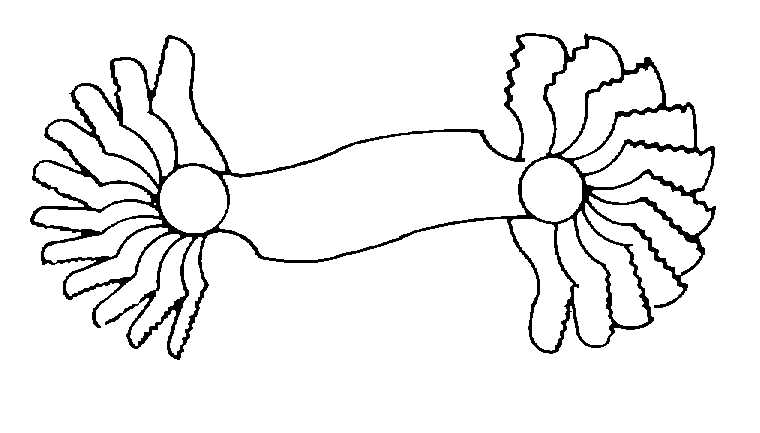

3-13. Thread Gauges. Thread gauges are used to

determine the pitch and number of threads per inch on

threaded fasteners. They consist of leaves whose

edges are toothed to correspond to standard threads. A

typical thread gauge is shown in figure 3-52.

Figure 3-52. Thread Gauge

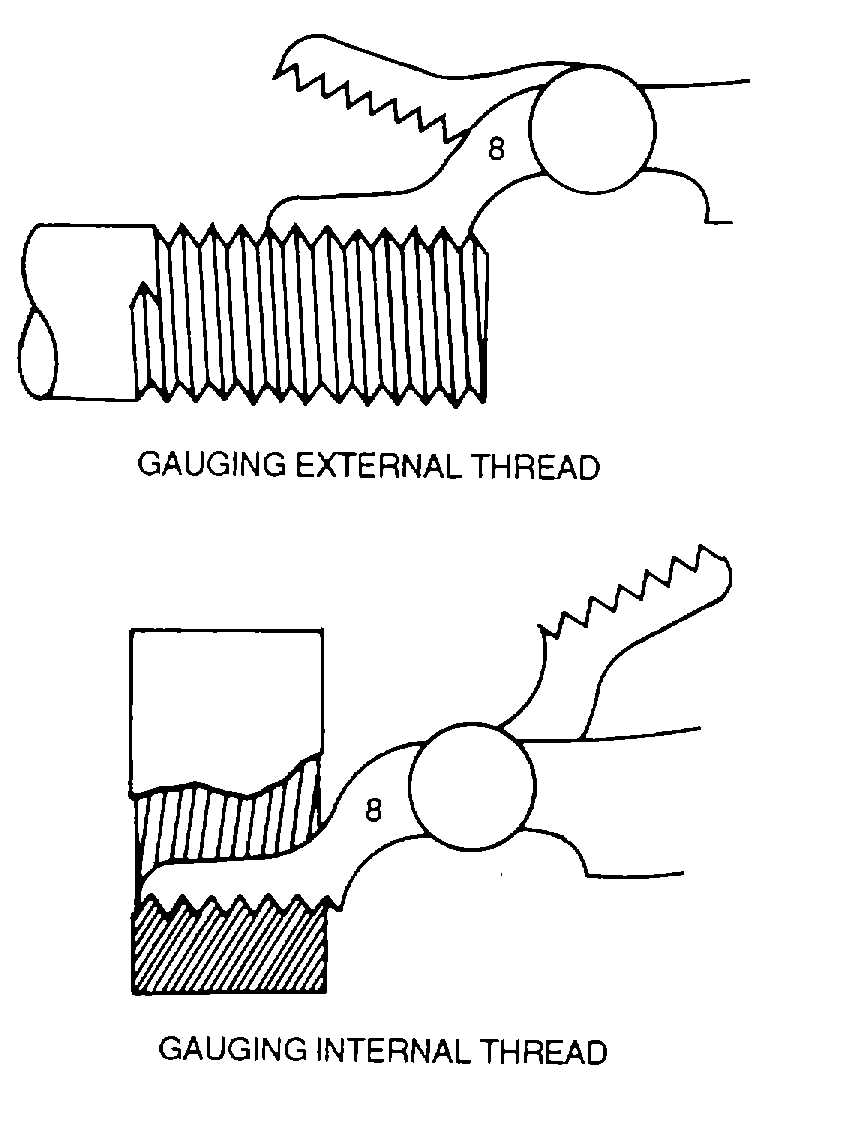

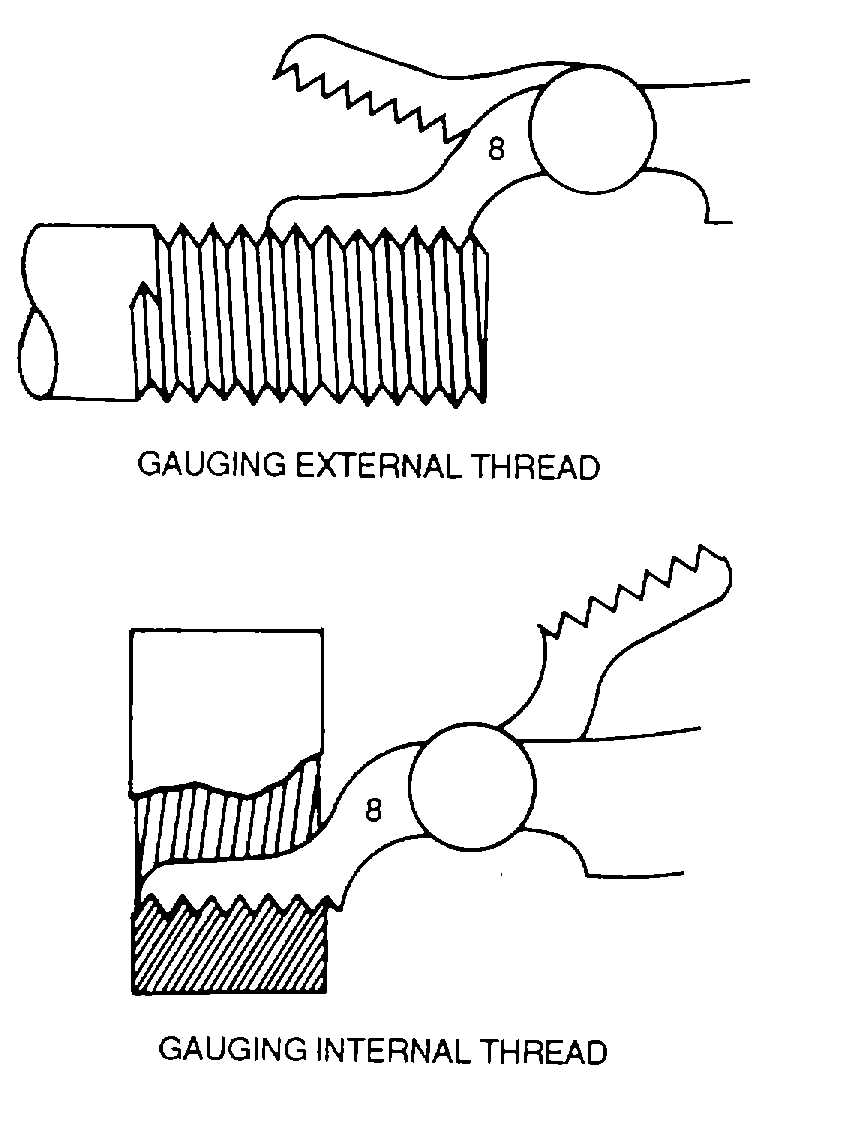

a.

Use. To measure the unknown pitch of a

thread, compare it with the standard of the thread

gauge. Various leaves are held to the threads until an

exact fit is found, as shown in figure 3-53.

b.

Reading. The number of threads per inch is

indicated on the leaf which is found to exactly match the

threads being measured. Using this value as a basis,

correct sizes of nuts, bolts, screws, taps, and dies are

selected for use.

c.

Care. Observe the following practices for the

care and upkeep of thread gauges:

Figure 3-53. Using Thread Gauges

(1)

Coat metal parts of thread gauges with a

light film of oil to prevent rust.

(2)

Store gauges in separate containers.

(3)

Keep graduations and markings clean and

legible.

(4)

Do not drop thread gauges. Small nicks

and scratches will result in inaccurate measurements.

3-14. Plug Gauges. Thread gauges provide a fast and

reliable method of determining whether internal and

external threads match. One disadvantage of their use

is that part of the thread tolerance must be built into the

thread gauge. For more precise measurement of thread

pitch, plug gauges are used.

a.

Use. GO and NO GO plug gauges are used to

inspect internal threads. They are available as separate

tools or with both ends combined in one tool, as shown

in figure 3-54. Threads are inspected as follows:

(1)

GO gauge. For an internal thread to be

accepted, the GO plug gauge must pass through the

entire length of the thread.

3-24