TM 1-1500-204-23-9

CHAPTER 4

GENERAL MAINTENANCE TOOLS

4-1. General. The general maintenance tools covered

in this chapter are those tools which are most commonly

used in the maintenance of Army aircraft. Regardless of

the type of work to be done, a mechanic must select and

use the correct tools in order to do his work quickly,

accurately, and safely. Without the correct tools and the

knowledge to use them, he wastes time, reduces his

efficiency, and may even injure himself. This chapter

explains the purposes, correct use, and proper care of

the more common tools.

4-2. Hammers and Mallets. Hammers are striking

tools which are composed of a head made of metal,

plastic, leather, or wood mounted on a handle. The

handle is usually made of wood, although some modern

hammers and mallets have handles made of fiberglass.

a.

Types. The more common types of

hammers and mallets are described in the following

paragraphs.

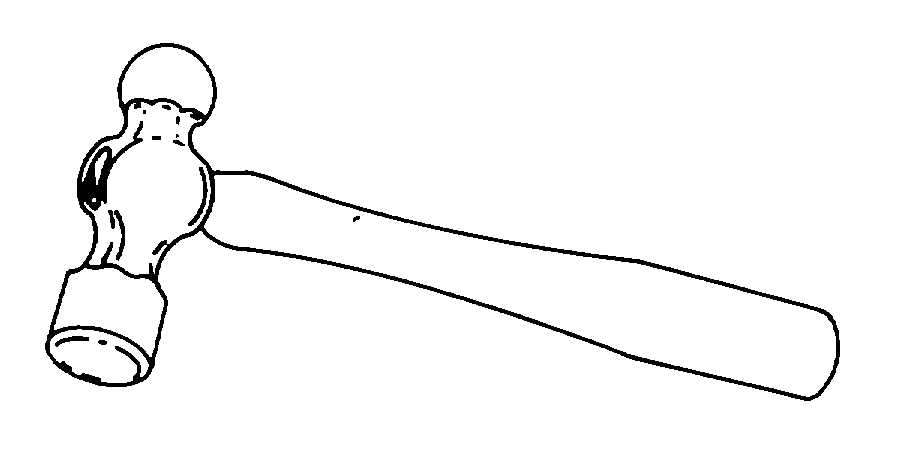

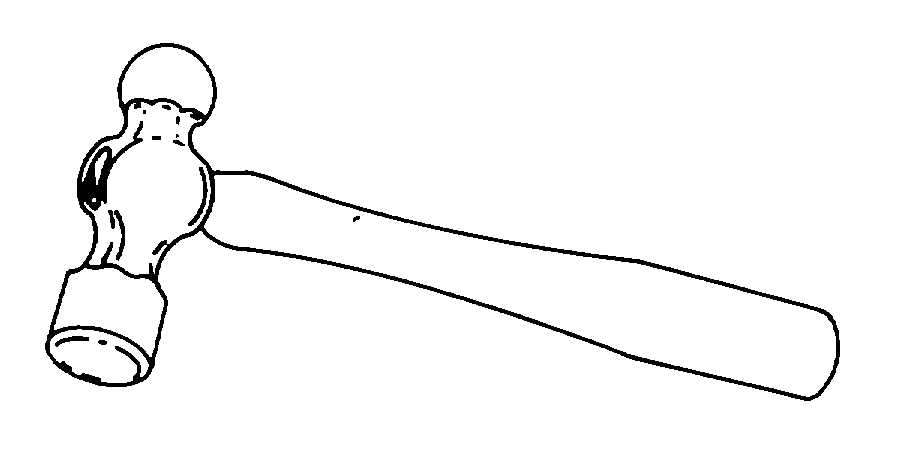

(1)

Ball peen hammer. The ball peen

hammer is the type most often used by mechanics. It

has a steel head and is usually available in 4-, 6-, 8-,

and 12ounces, and 1, 1 1/2-, and 2-pounds. As figure 4-

1 shows, this hammer is identified by the ball-shaped

peen at the opposite end of the face.

Figure 4-1. Ball Peen Hammer

(2)

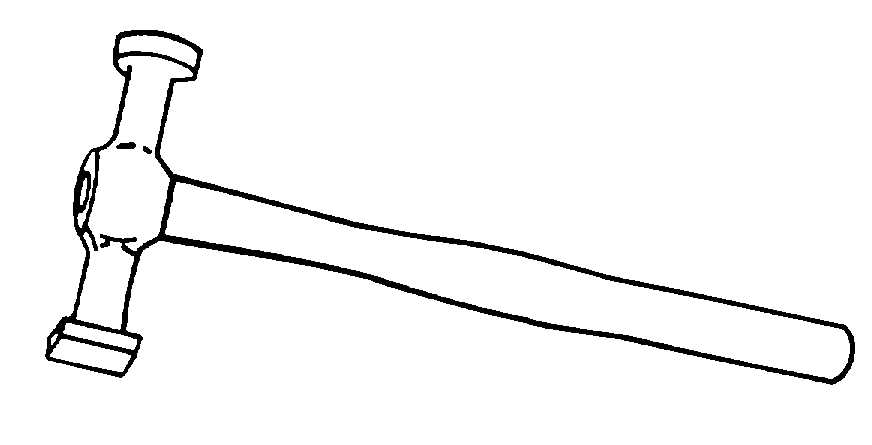

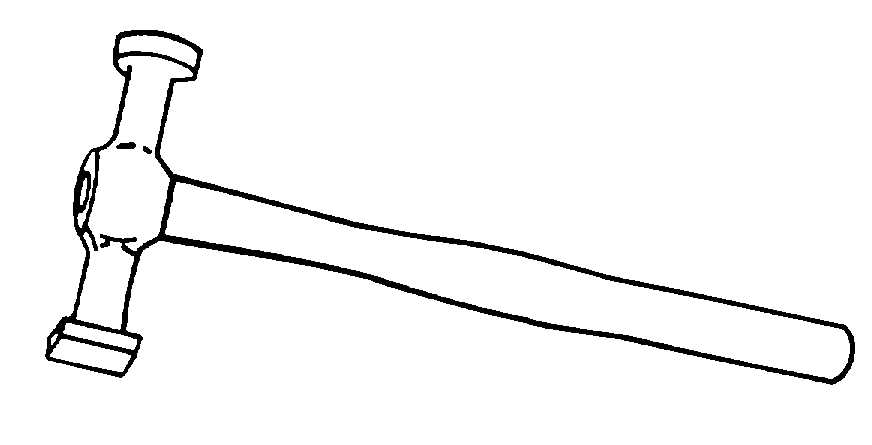

Body hammer. A body hammer,

shown in figure 4-2, is used to straighten and form

metal.

(3)

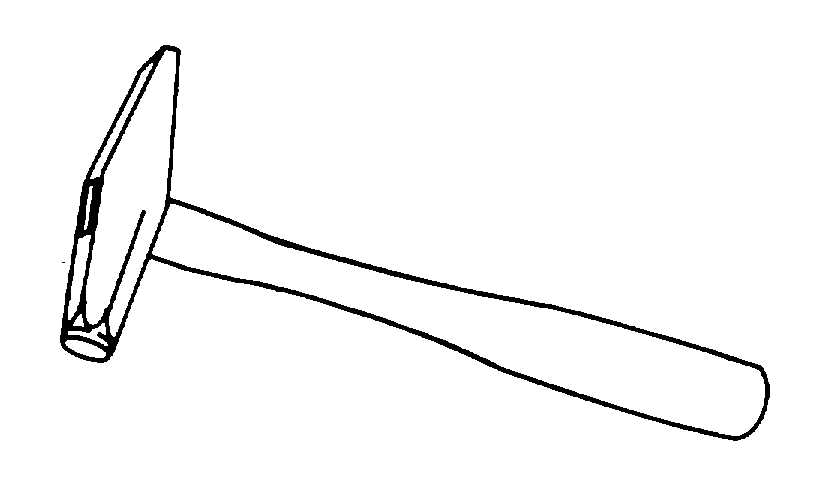

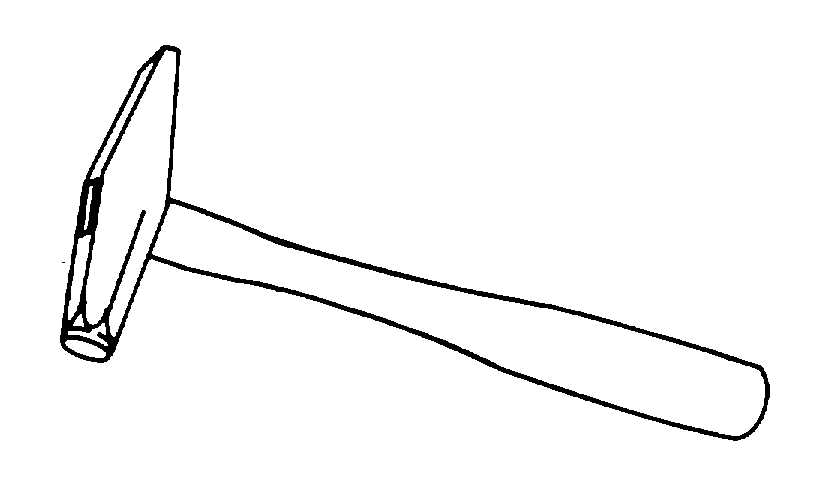

Riveting

hammer.

The

riveting

hammer, shown in figure 4-3, is used for driving rivets

and for light chiseling. One end of the head is cross

peened. The other end may have either a square or a

chamfered face.

Figure 4-2. Body Hammer

Figure 4-3. Riveting Hammer

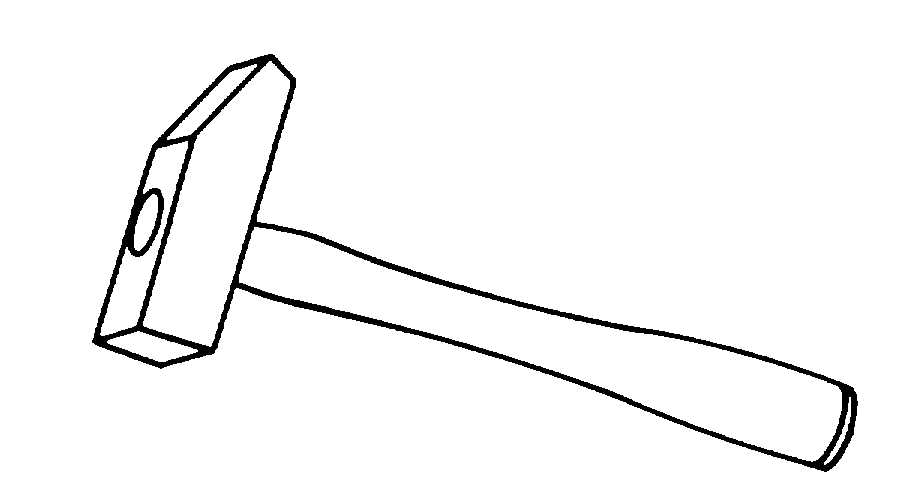

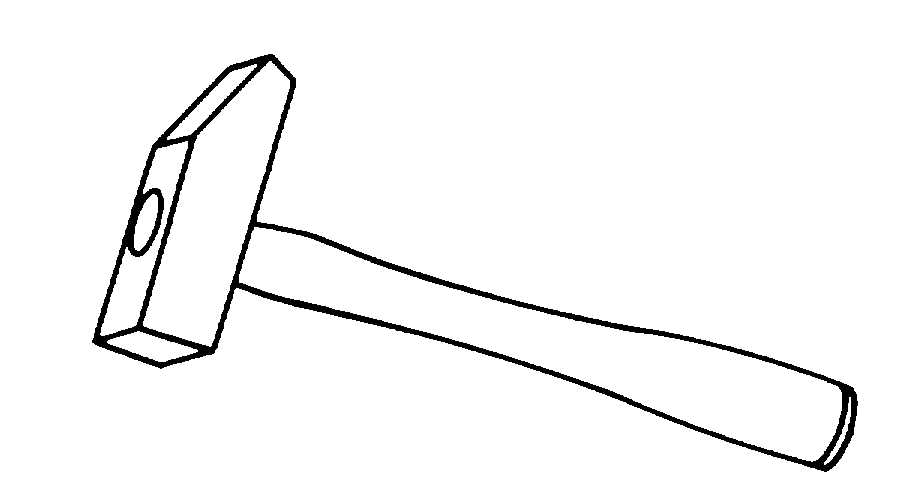

(4)

Setting hammer. The setting hammer

has a square flat face on one end of the head and a

sloping beveled edge on the other end. It is used in

sheet metal work for leveling and bending edges and for

setting double seams. An example of this type of

hammer is shown in figure 4-4.

Figure 4-4. Setting Hammer

4-1