TM 1-1500-204-23-9

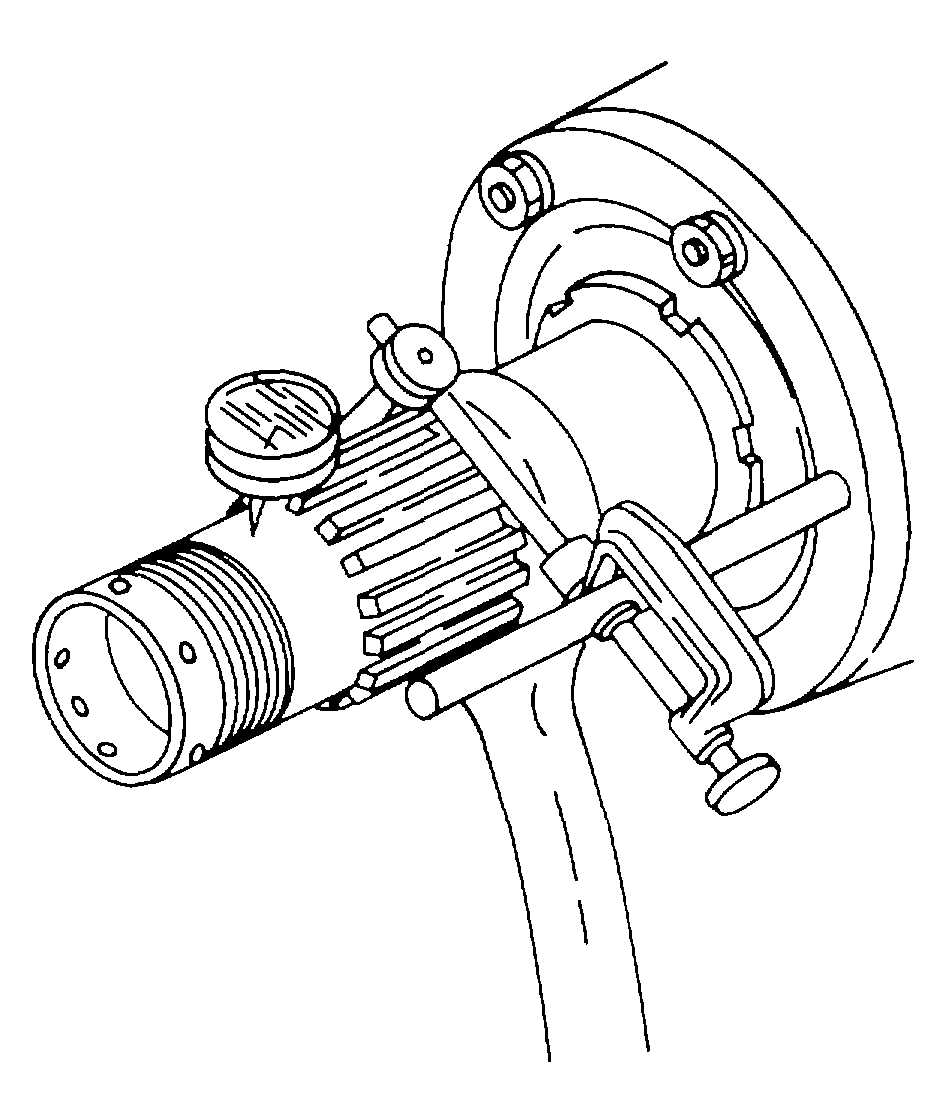

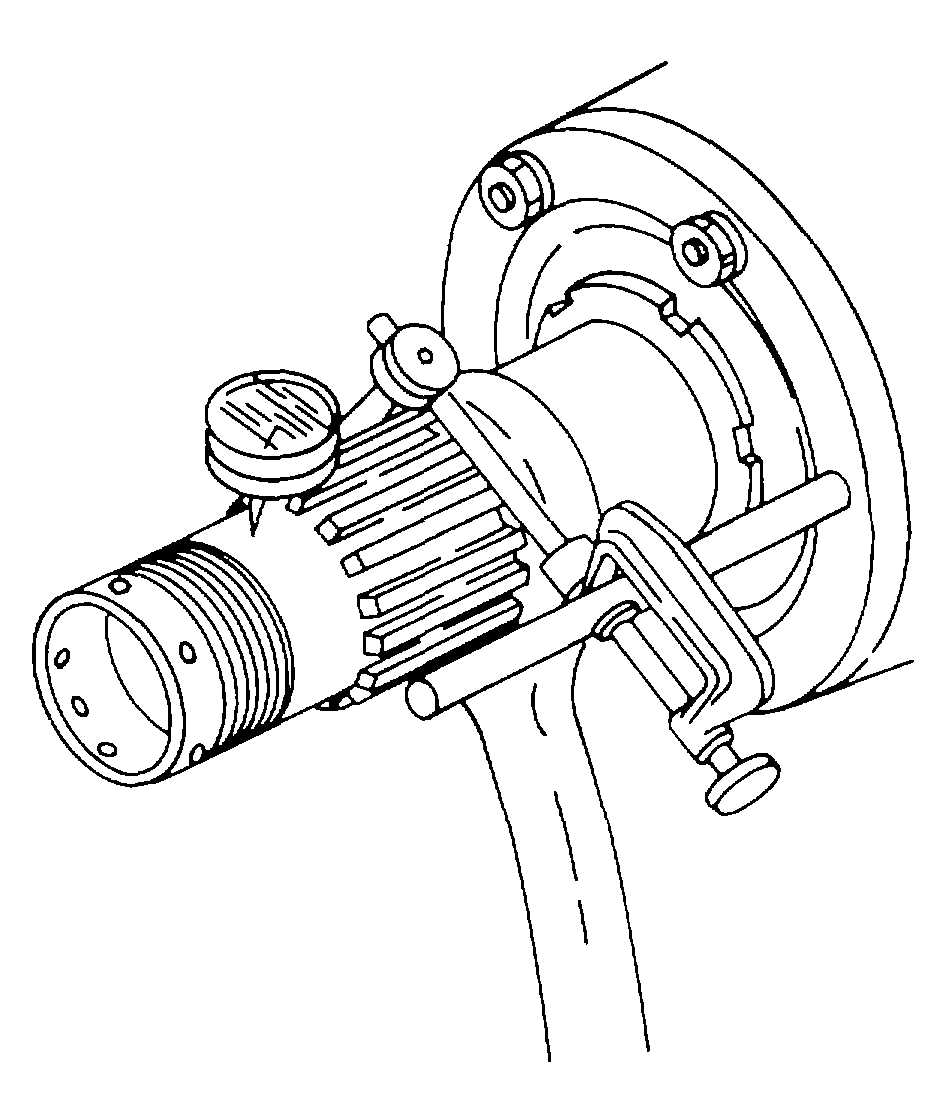

Figure 3-76. Checking Propeller Shaft Run Out

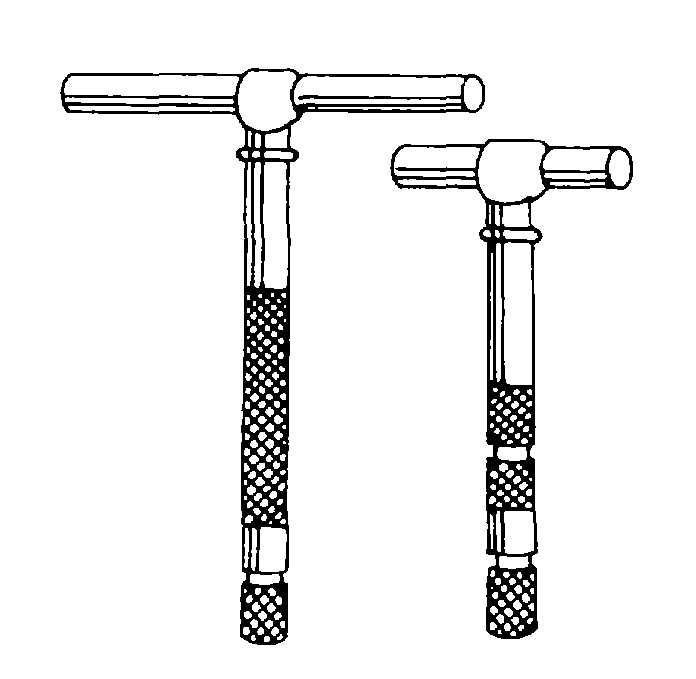

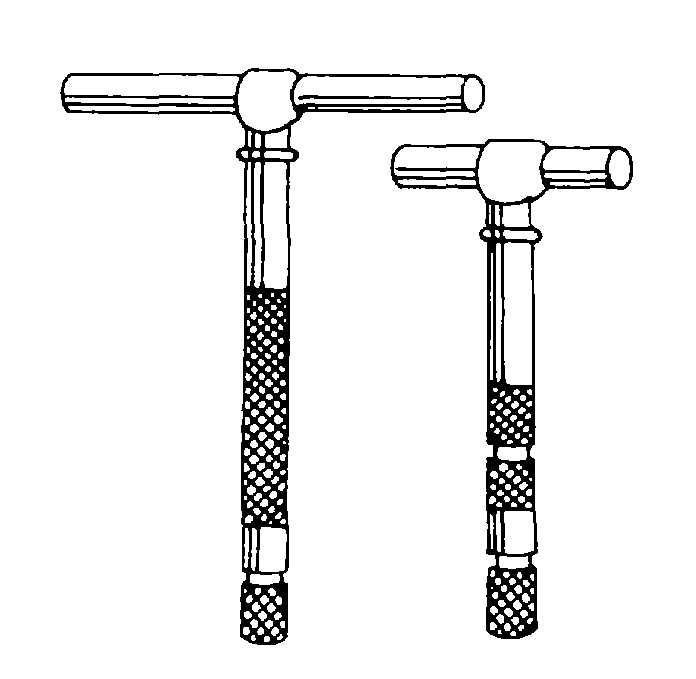

Figure 3-77. Telescoping Gauges

b.

Use. To use the gauge, the arms are

compressed, placed in the hole to be measured, and

allowed to expand. A twist of the locknut on top of the

handle locks the arms. The tool may then be withdrawn

and the distance across the arms measured. To measure

the diameter of a hole from 1/2 to 6 inches in diameter,

select the tool with the proper range and proceed as

follows:

(1)

Loosen the knurled nut at the end of the

handle.

(2)

Telescope the adjustable end of the

gauge of a size slightly smaller than the hole, and retighten

the nut.

(3)

Insert the gauge into the hole as shown

in figure 3-78.

(4)

Loosen the nut to permit the spring-

loaded adjustable end to expand to the hole diameter, and

tighten the nut. The spring-loaded feature will assure

proper contact.

NOTE

Ensure that the gauge is held with the

telescoping end at right angles to the axis of

the hole to measure the true diameter.

(5)

Remove the gauge and measure the

setting with an outside micrometer.

c.

Care. Observe the following practices for the

care and upkeep of telescope gauges:

(1)

Coat metal parts of telescope gauges

with a light film of oil to prevent rust.

(2)

Store gauges in separate containers.

(3)

Keep graduations and markings clean

and legible.

(4)

Do not drop telescope gauges. Small

nicks and scratches will result in inaccurate measurements.

3-22. Small Hole Gauges. For measuring smaller slots or

holes than the telescoping gauges will measure, small hole

gauges can be used. These gauges come in sets of four or

more and will measure distances of approximately 1/8 to

1/2 inch. They are shown in figure 3-79.

3-36