TM 1-1500-204-23-9

7

Select the metal wedge and drive it into

the wooden wedge with a hammer.

WARNING

Wear eye protection when grinding

metal on a bench grinder. Failure to

comply may result in serious injury to

personnel.

8

Remove the excess portion of the metal

wedge using a bench grinder.

(4)

Repairing uneven face wear. Uneven face wear

can be repaired by reshaping the worn faces, using the

following procedures:

(a)

Determine the original shape of the face

by examining an unworn portion or comparing the

hammer to be repaired with another of the same type.

WARNING

Wear eye protection when grinding

metal on a bench grinder. Failure to

comply may result in serious injury to

personnel.

(b)

Grind the face to the original shape,

dipping in water frequently to avoid overheating.

NOTE

•

Remove only the amount of stock

necessary to repair the face.

•

When grinding mallets, remove equal

amounts of stock from both faces to

retain balance.

4-3. Screwdrivers. Screwdrivers are tools used for

driving or removing screws. Generally, they consist of a

steel blade and shank set in a handle of wood or plastic.

However, they come in various other shapes, some

being adapted to a particular usage. A large variety of

sizes is available.

a.

Types. There are many types of screwdrivers

used in the maintenance of Army aircraft. The following

paragraphs describe the types most commonly used.

(1)

Common

screwdriver.

The

common,

or

standard, screwdriver, shown in figure 4-13, is suitable

for driving or removing slotted screws. The blade must

have sharp corners and fit the screw slot closely. The

size is designated by the length of the shank and blade.

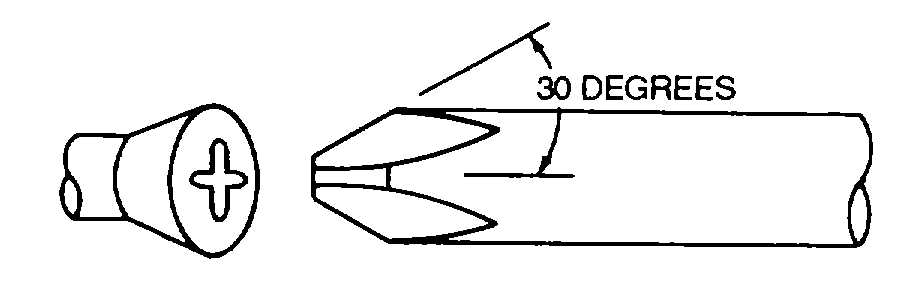

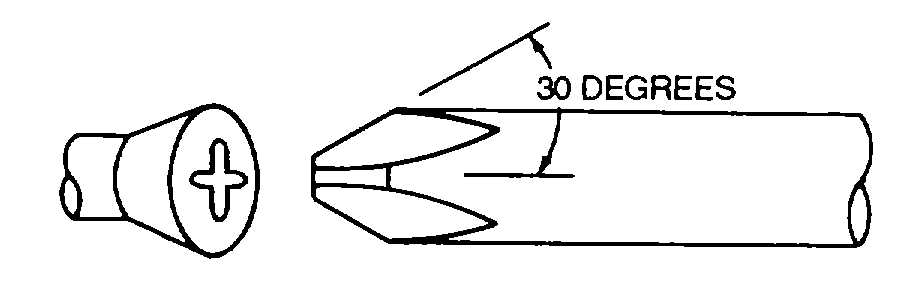

(2)

Phillips screwdriver. The Phillips screwdriver

has a blunt cross tip. The tip is ground to a 30-degree

angle, as shown in figure 4-14.

NOTE

The Phillips screwdriver is not inter-

changeable with the Reed and Prince

screwdriver. The use of the wrong type

screwdriver results in mutilation of the

screwdriver and the screw head.

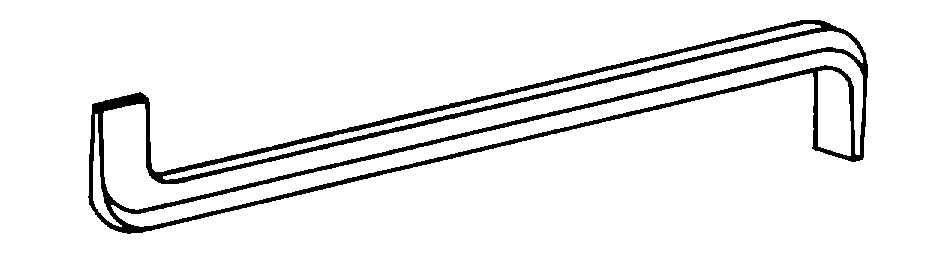

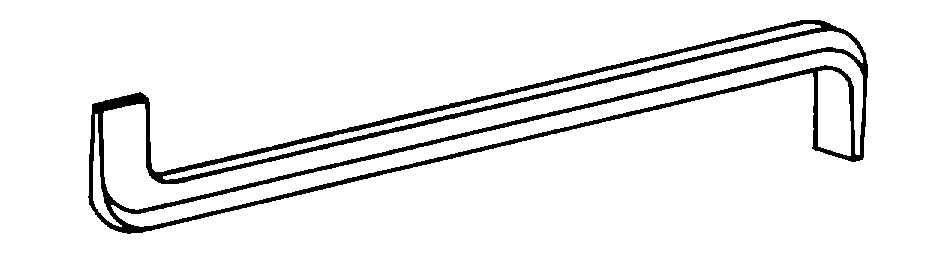

(3)

Offset screwdrivers. The offset screwdriver

shown in figure 4-15 is composed of a shank with a

blade on each end. The blades are bent at right angles

to the shank. One is parallel to the shank, the other is

set at 90 degrees. This screwdriver is especially

usefully in performing close work. Some offset

screwdrivers are

Figure 4-13. Common Screwdriver

Figure 4-14. Phillips Screwdriver

Figure 4-15. Offset Screwdriver

4-5