TM 1-1500-204-23-9

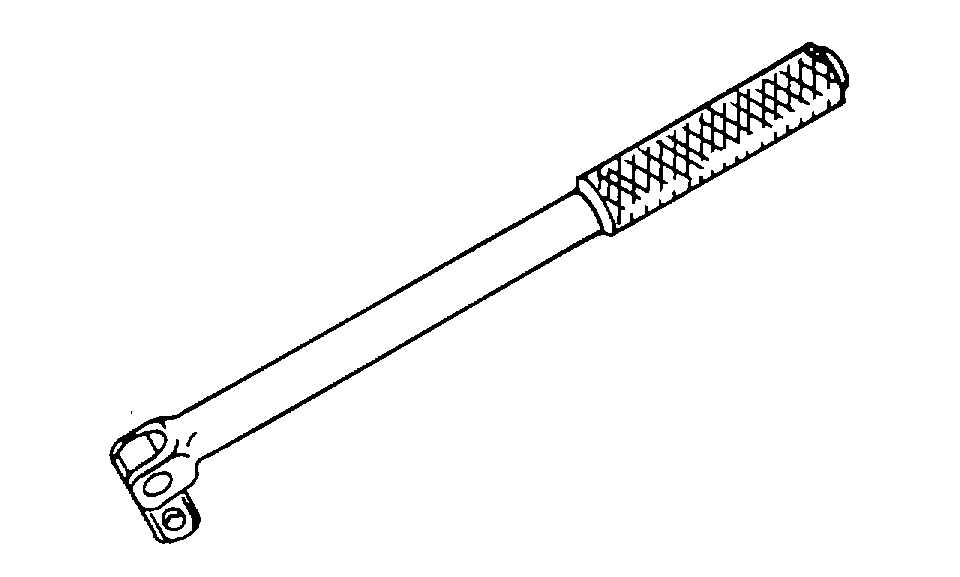

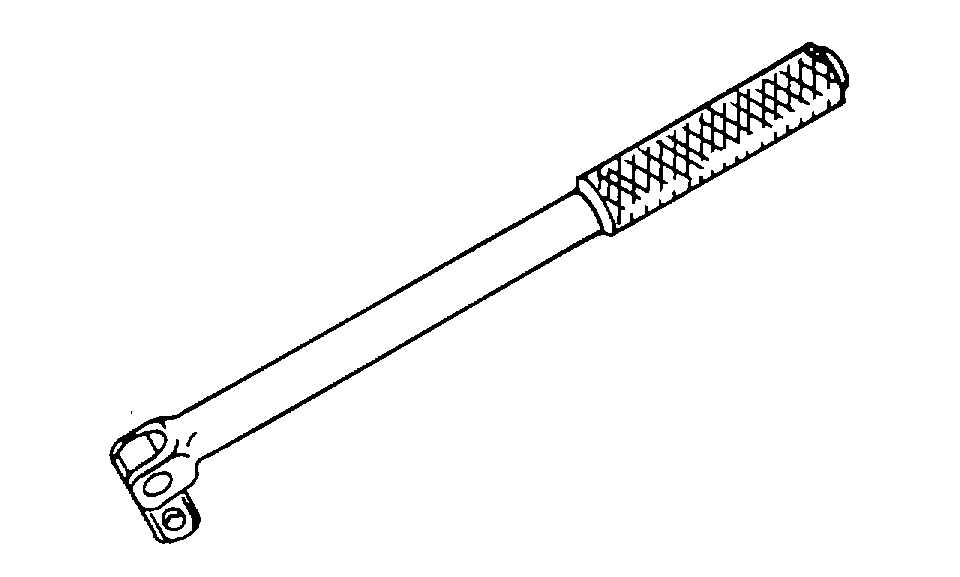

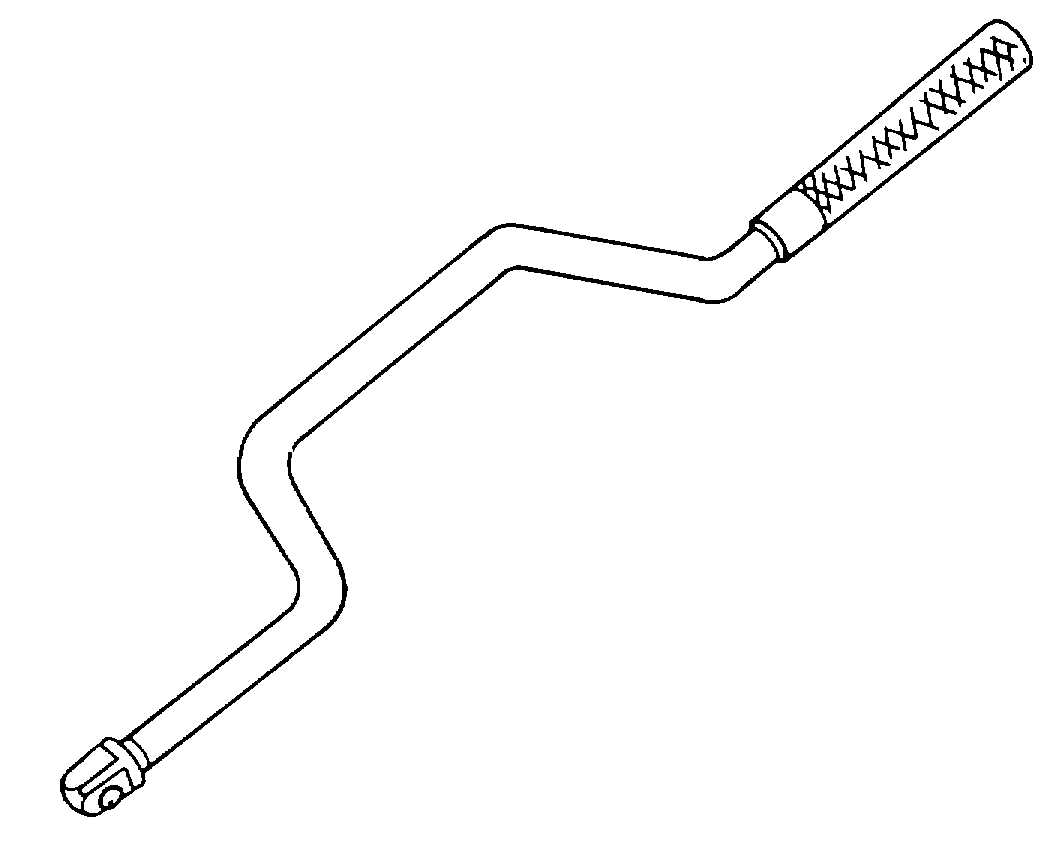

Figure 4-29. Hinged Handle

4

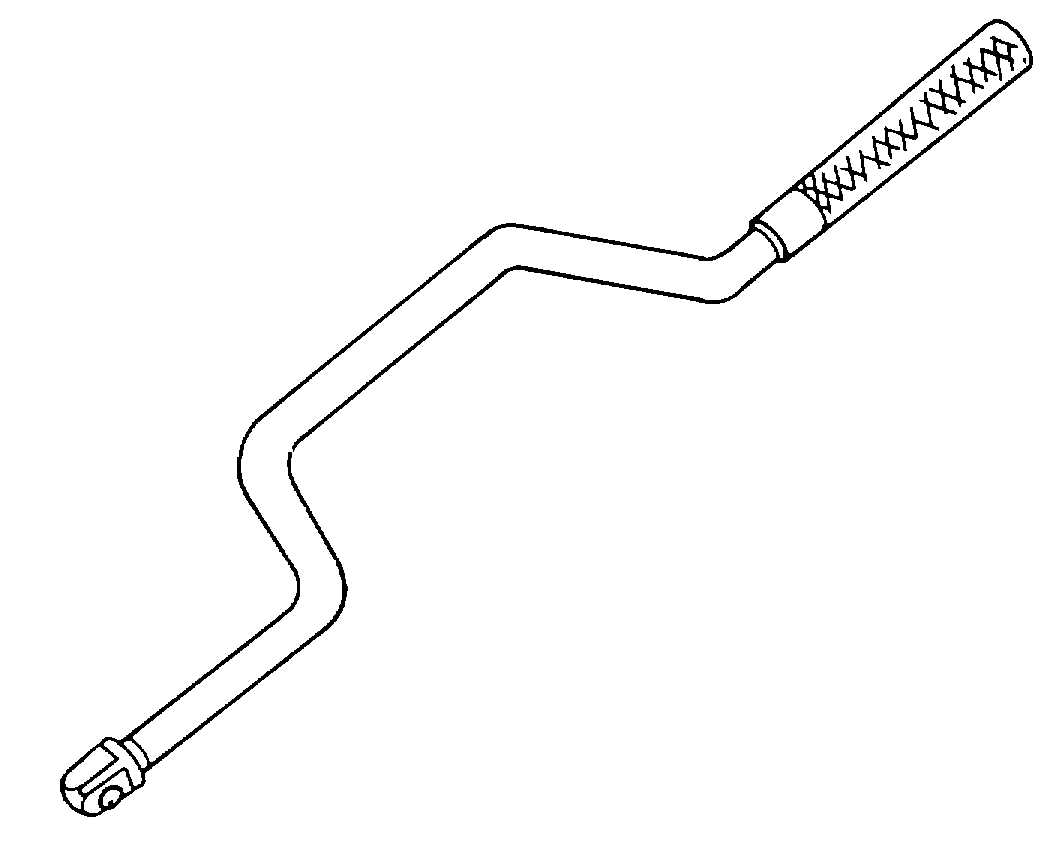

Speed handle. The speed handle, shown

in figure 4-30, has a brace-type shaft with a revolving

grip on the top. It is used for rapid removal and/or

installation of nuts or bolts, which are out in the open

and have little or no torque.

Figure 4-30. Speed Handle

(6)

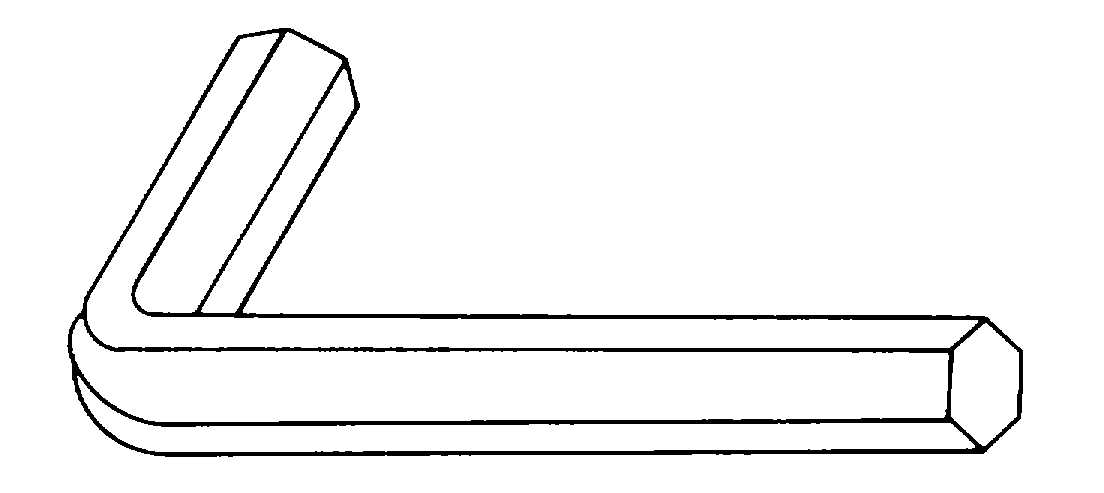

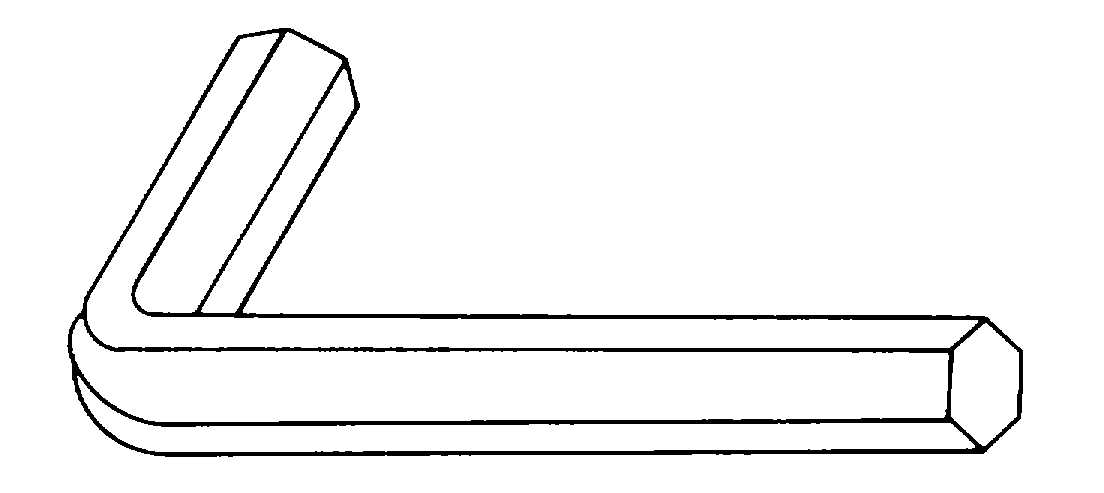

Hexagonal wrenches. Hexagonal setscrew

wrenches (Allen wrenches) are L-shaped, headless,

hexagonal bars that range in size from 3/64-to 1/2-inch.

A typical Allen wrench is shown in figure 4-31. They are

used in tightening or removing screws that have

hexagonal recesses.

b.

Uses. When using any type wrench, special

attention should be given to choosing the one best

suited for

Figure 4-31. Hexagonal Setscrew Wrench (Allen

Wrench)

the job. Selecting a wrench larger than the nut or bolt

head will often result in rounded corners and additional

maintenance time. Arrange work so a wrench is pulled,

not pushed. Never use pipe or other extensions to

increase leverage. The following paragraphs describe

the various procedures involved with operating the

previously described wrenches.

(1)

Use of open-end wrenches. The 15-degree

offset of the jaws from the centerline of the wrench

makes the open-end wrench appropriate for use in some

applications where there is room to make only a part of

a complete turn of a nut or bolt. A typical procedure for

this application is shown in figure 4-32 and outlined in

the following:

NOTE

Where conditions make it impossible to

use a socket or box-end, an open-end

wrench may be used. The open-end

wrench has fewer contact points than

either a socket or box-end and is more

likely to round off the corners of the nut.

(a)

Step 1 shows the wrench, with the

opening sloping to the left, about to be placed on the

nut.

(b)

Position the wrench on the nut (step 2).

Note that space for swinging the wrench is limited.

(c)

Move the wrench clockwise to tighten the

nut. The wrench will strike the casting which prevents

further movement (step 3).

(d)

Remove the wrench from the nut and turn

counterclockwise to place it on the next set of flats on

the nut.

4-10