TM 1-1500-204-23-9

available as ratchet-types, which allow the screw to be

driven without having to remove the tip from the screw

head.

(4)

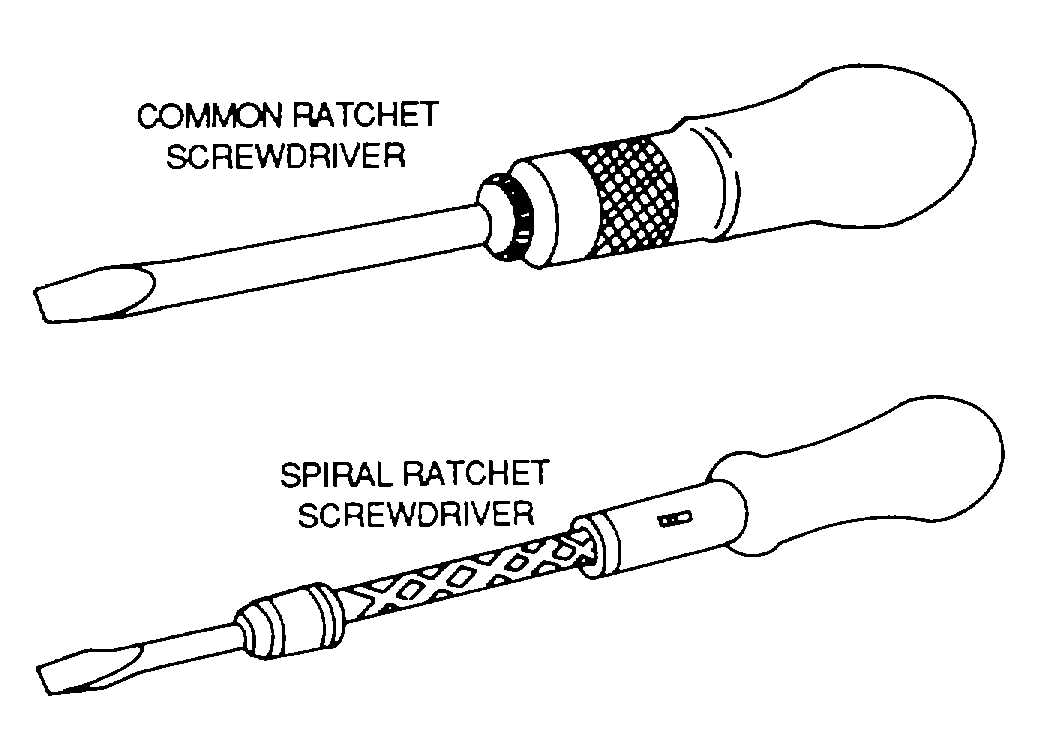

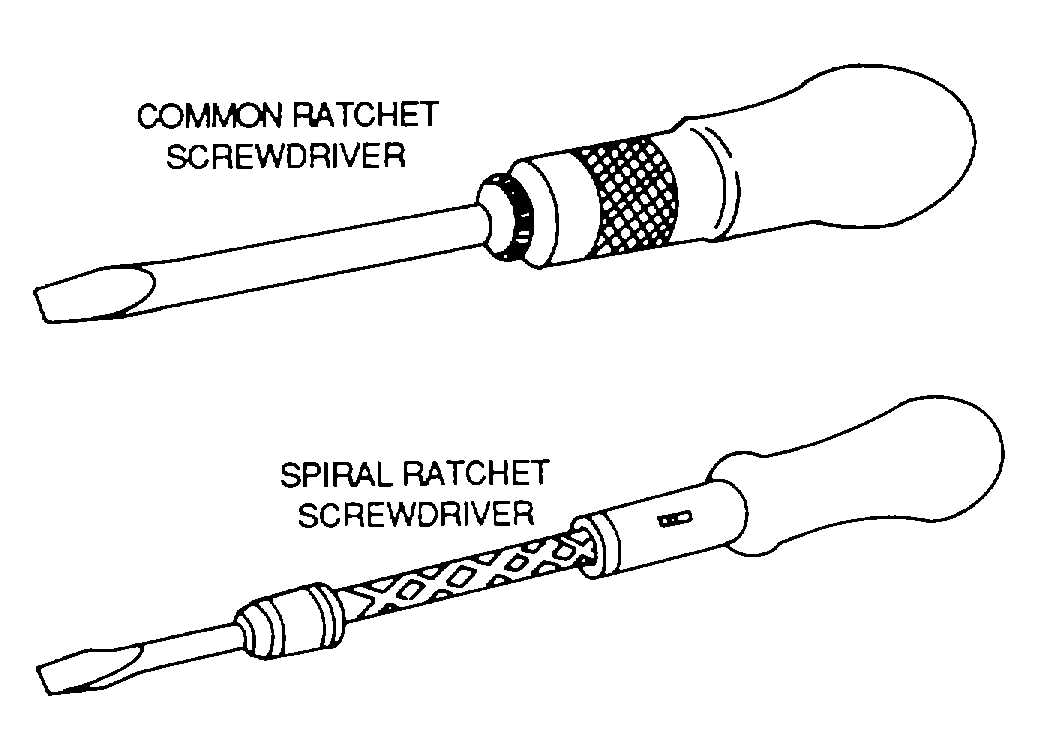

Ratchet screwdrivers. The ratchet, or spiral,

screwdriver shown in figure 4-16 is fast acting in that it

turns the screw when the handle is pulled back and then

pushed forward. It can be set to turn the screw either

clockwise or counterclockwise, or it can be locked in

position and used as a standard screwdriver. The

ratchet screwdriver is not a heavy-duty tool and should

be used only for light work.

Figure 4-16. Ratchet Screwdrivers

NOTE

When

using

a

spiral

or

ratchet

screwdriver, extreme care must be used

to

maintain

constant

pressure

and

prevent the blade from slipping out from

the slot in the screw head. If this occurs,

the surrounding structure is subject to

damage.

(5)

Nonmagnetic screwdriver. The nonmagnetic

screwdriver is shaped like a common screwdriver, but

the blade is made of brass so as to have no magnetic

effect. It is used for compensating compasses.

b.

Safety. The following precautions must be kept

in mind when using screwdrivers:

Ensure that the handle of the screwdriver

is clean.

•

Do not use a screwdriver for prying,

punching, chiseling, scoring, or scraping.

•

Do not use a screwdriver to check an

electric circuit since an electric arc will

burn the tip and make it useless. In some

cases, an electric arc may fuse the blade

to the unit being checked.

•

When using a screwdriver on a small

part, always hold the part in the vise or

rest it on a workbench. Do not hold the

part in the hand, because the screwdriver

may slip and cause serious personal

injury.

c.

Use The following paragraphs describe the use

of various types of screwdrivers.

(1)

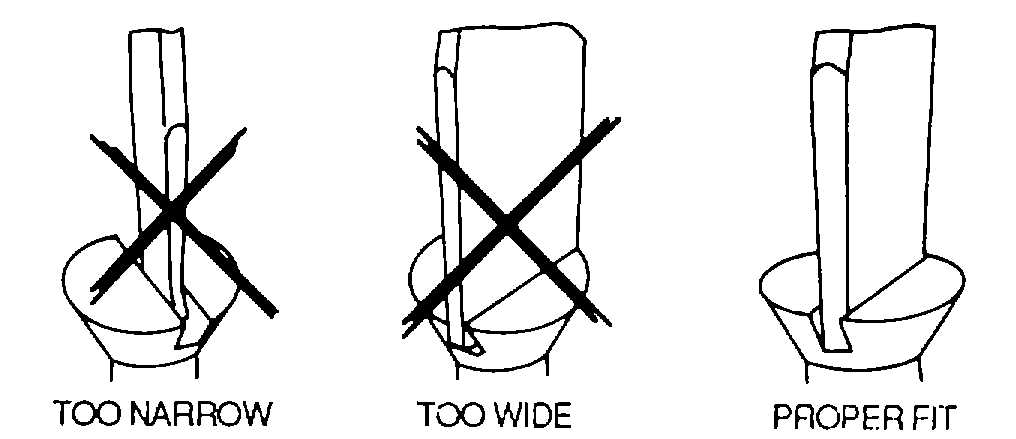

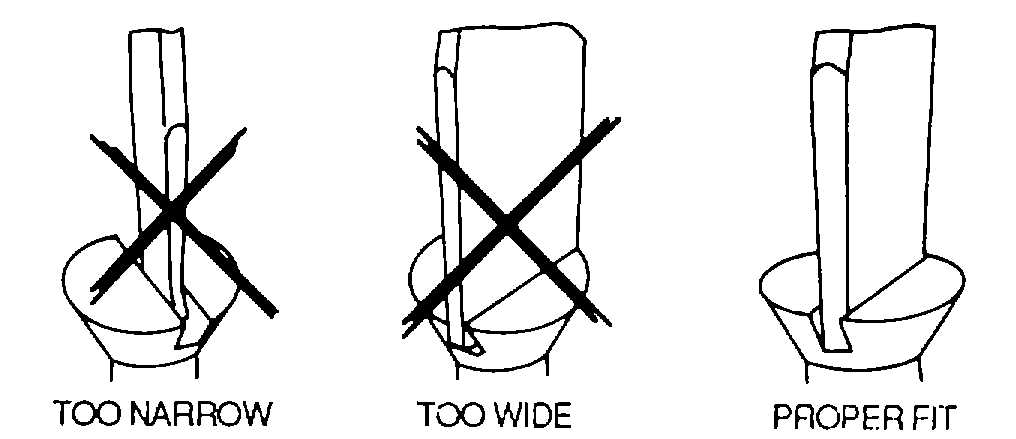

Proper fit. Select a screwdriver large enough so

the blade fits closely in the screw slot. A loose fitting

blade can slip and cause burring of the screw slot and

damage to the blade. Proper and improper fits are

shown in figure 4-17. It is important that the screwdriver

be held firmly against the screw to prevent it from

slipping and possibly injuring the mechanic or scarring

the work.

(2)

Use of screwdriver. A screwdriver is used as

follows:

(a)

Insert the screwdriver tip into the screw

slot of the screw.

(b)

Turn the screw as required. Keep the

screwdriver in line with the screw.

(3)

Use of offset screwdriver. The procedure for

using an offset screwdriver is as follows (see figure 4-

18):

Figure 4-17. Proper Fit of Screwdrivers

4-6